Oil-absorbing carbon sponge and preparation method thereof

A sponge and oil-carbon technology, applied in the field of materials, can solve the problems of expensive, difficult to reuse, easy to be damaged, etc., and achieve the effects of excellent mechanical properties, fast oil-water separation, and excellent hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

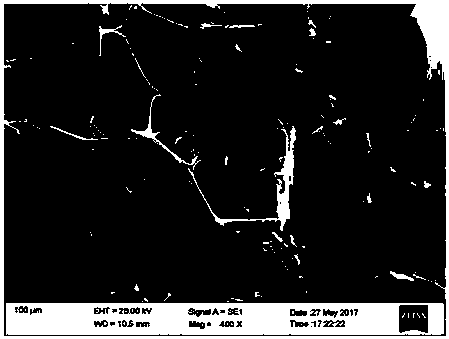

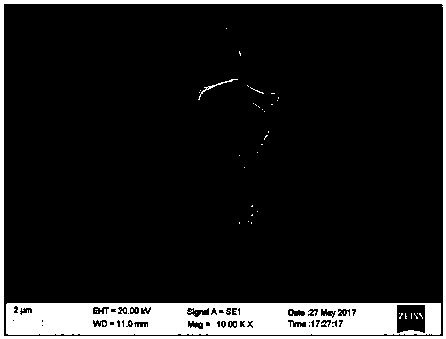

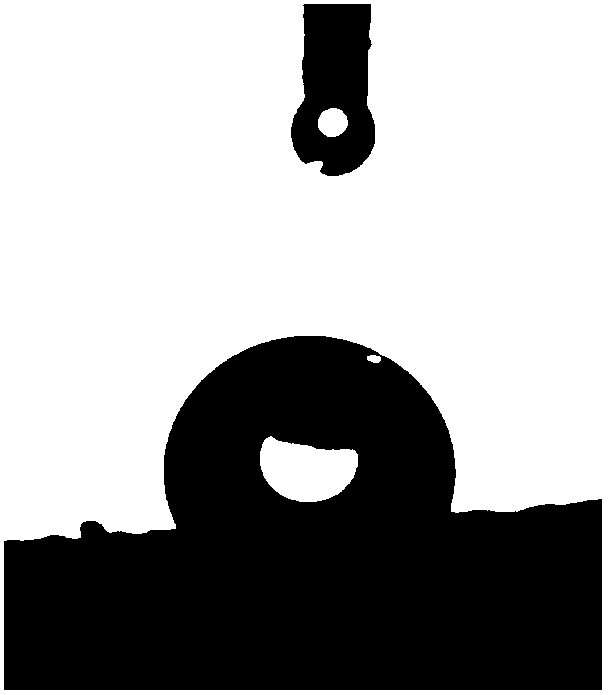

Image

Examples

Embodiment

[0023] First, cut the commercial sponge, that is, the melamine sponge, into a suitable size, and then ultrasonically clean the melamine sponge with ultrapure water for 3 to 5 times;

[0024] Specifically, the purpose of ultrasonic cleaning is to wash off the dust and impurities on the surface of commercial sponges, so that graphene oxide can be better loaded on the sponges;

[0025] Ultrasonic cleaning with ethanol solution and drying;

[0026] Specifically, the purpose of cleaning with ethanol is to:

[0027] (1) In order to dissolve some organic impurities;

[0028] (2) After cleaning the sponge, use ethanol solvent instead of water to make the sponge dry faster.

[0029] Adjust the concentration of graphene oxide to an appropriate range: 0.5~5mg mL -1 ;

[0030] Put the dried sponge into graphene oxide of known concentration and disperse it ultrasonically (ultrasonic frequency: 59kHz; temperature: room temperature; time: half an hour) to obtain a graphene oxide-coated m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com