Preparation method of catalyst for preparing cyclohexanol from cyclohexene and application of catalyst

A catalyst, cyclohexene technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of short catalyst service life, complex product recovery, poor thermal stability, etc., achieve high conversion rate, preparation Advanced technology, strong water-oil amphiphilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

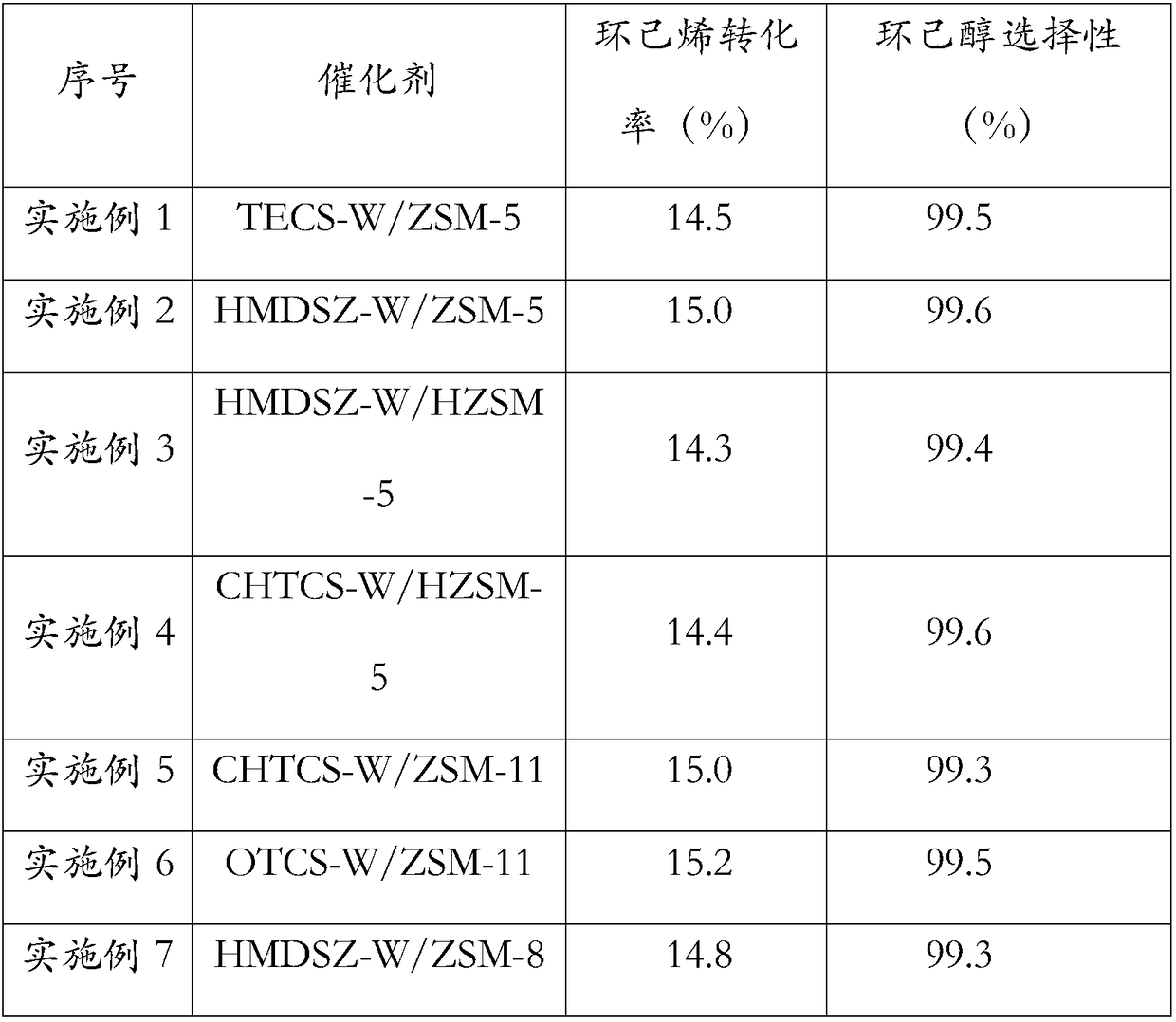

Examples

Embodiment 1

[0030] Weigh 1.0g of WO 3 Soaked in organic acid A for 30min, filtered to obtain acidified solid WO 3 . 1.0 g acidified solid WO 3 , 300.0g polyvinylpyrrolidone (PVP), 500.0g ZSM-5 molecular sieve, mix well, place the mixture in a microwave reactor with a power of 300W, heat it to 250°C under microwave radiation, and obtain a tungsten catalyst carrier W / ZSM- 5.

[0031] Put 10g of W / ZSM-5 catalyst into 100ml of 0.1g / ml triethylchlorosilane-toluene solution, put it in a microwave reactor, and under the action of nitrogen flow, radiate and heat to 55°C, radiate for 15min, and filter , The solid was calcined at 120°C for 3h. The obtained heterogeneous supported catalyst is designated as TECS-W / ZSM-5.

[0032] Add 10g of titanium-loaded TECS-W / ZSM-5 catalyst, 120g of cyclohexene, and 110g of water into a 500ml autoclave, close the autoclave, replace the air with high-purity nitrogen, heat to 120°C, stir, and react for 2h , filtered, the organic phase was analyzed by gas chro...

Embodiment 2

[0034] Weigh 1.0g of WO 3 Soaked in organic acid A for 40min, filtered to obtain acidified solid WO 3 . 1.0 g acidified solid WO 3 , 350.0g polyvinylpyrrolidone (PVP), 550.0g ZSM-5 molecular sieve, mix well, place the mixture in a microwave reactor with a power of 300W, heat it to 250°C under microwave radiation, and obtain a tungsten catalyst carrier W / ZSM- 5.

[0035] Put 10g of W / ZSM-5 catalyst into 50ml of 0.1g / ml hexamethyldisilazane-toluene solution, put it in a microwave reactor, and heat it to 50°C under the action of nitrogen flow, and radiate for 20min , filtered, and the solid was calcined at 110°C for 4h. The obtained heterogeneous supported catalyst is designated as HMDSZ-W / ZSM-5.

[0036] Add 10g of titanium-loaded HMDSZ-W / ZSM-5 catalyst, 120g of cyclohexene, and 100g of water into a 500ml autoclave, close the autoclave, replace the air with high-purity nitrogen, heat to 150°C, stir, and react for 2h , filtered, the organic phase was analyzed by gas chromat...

Embodiment 3

[0038] Weigh 1.0g of WO 3 Soaked in organic acid A for 50min, filtered to obtain acidified solid WO 3 . 1.0 g acidified solid WO 3 , 400.0g polyvinylpyrrolidone (PVP), 500.0gHZSM-5 molecular sieve, mix well, place the mixture in a microwave reactor with a power of 300W, and heat it to 250°C under microwave radiation. After 15min, the supported tungsten catalyst carrier W / HZSM- 5.

[0039] Put 10g of W / ZSM-5 catalyst into 6ml of 1.0g / ml hexamethyldisilazane-toluene solution, put it in a microwave reactor, and heat it to 40°C under the action of nitrogen flow for 15 minutes , filtered, and the solid was calcined at 90°C for 5h. The obtained heterogeneous supported catalyst is designated as HMDSZ-W / HZSM-5.

[0040] Add 10g of titanium-loaded HMDSZ-W / HZSM-5 catalyst, 100g of cyclohexene, and 200g of water into a 500ml autoclave, close the autoclave, replace the air with high-purity nitrogen, heat to 150°C, stir, and react for 2h , filtered, the organic phase was analyzed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com