Construction method of oil-producing yeast engineering strain by using methyl alcohol and application

An oil-producing yeast and engineering strain technology, applied in the fields of biotechnology and bioenergy, can solve problems such as inability to use methanol, and achieve the effects of reducing CO2 emissions and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

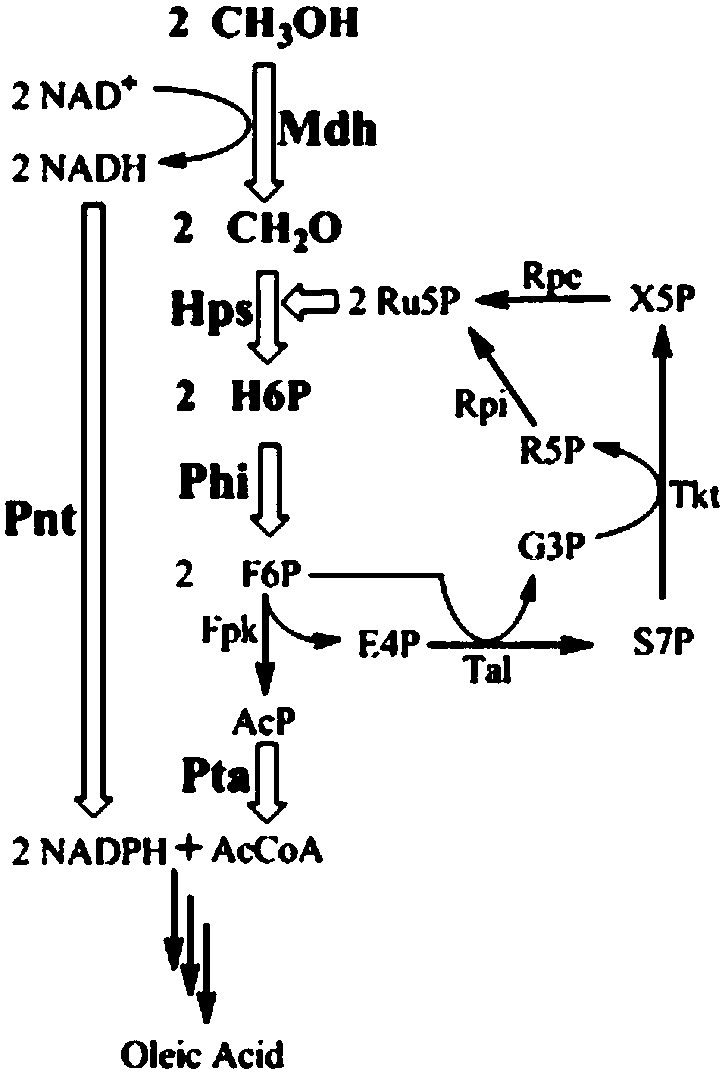

[0026] Recombinant Strain M-R1 Utilizes Methanol to Produce Oil

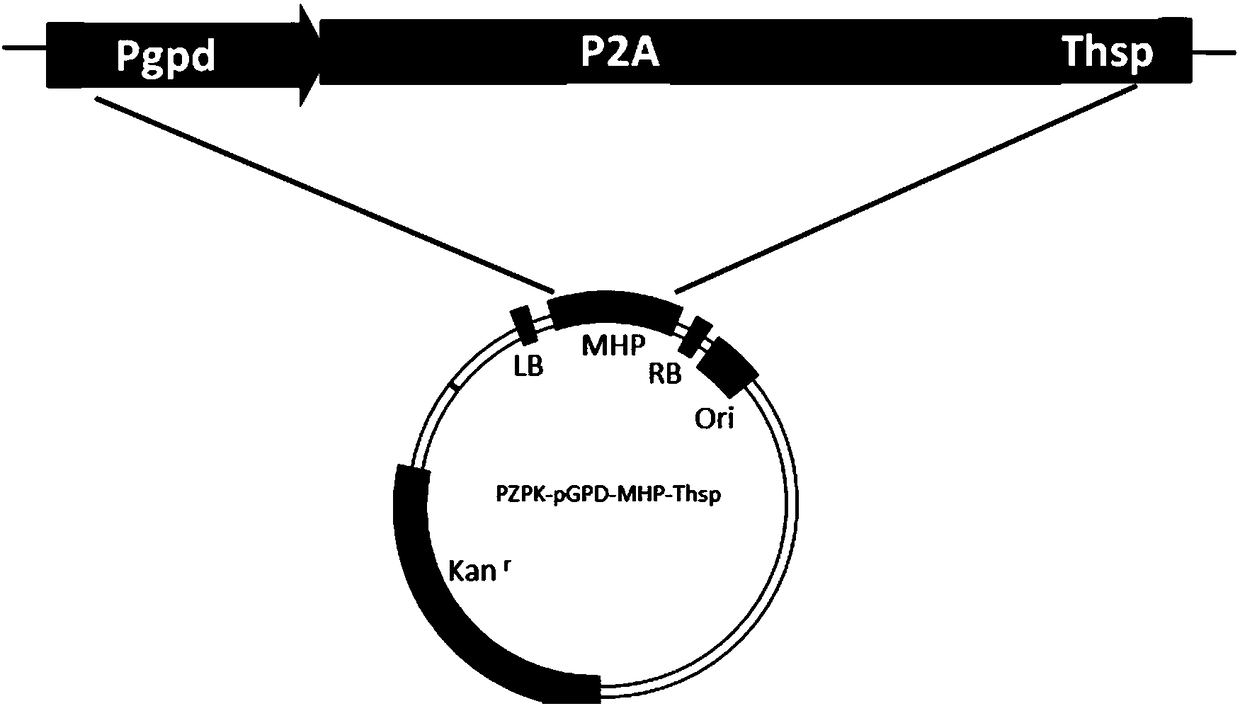

[0027] The oleaginous yeast Rhodosporidium toruloides CGMCC 2.1389 was purchased from China General Microorganism Culture Collection and Management Center. The recombinant strain M-R1 is an R. toruloides strain co-overexpressing MDH, HPS and PHI, and its construction process is as follows.

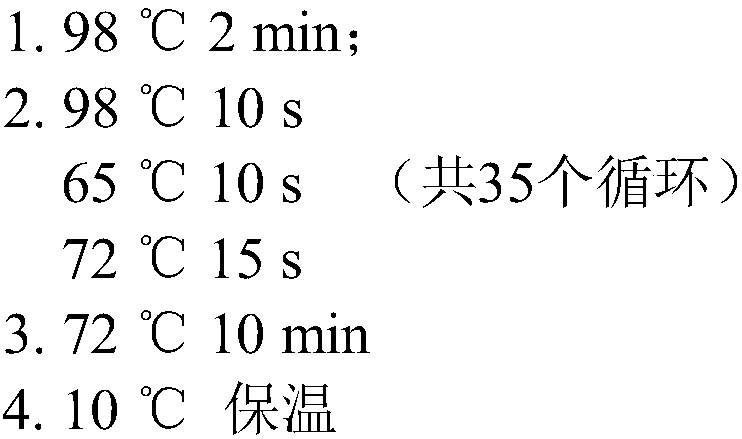

[0028] Step 1 Design the following primers according to the nucleotide sequence of GPD-p to construct the constitutive cloning vector pZPK (the underlined part of primer Pgpd-Xbal I-F is the XbaI restriction site, and the underlined part of primer Pgpd-Eco V-R is the EcoRV enzyme cutting site) wherein the specific primers used for cloning GPD-p are:

[0029] Pgpd-Xbal I-F 5'-CTAG TCTAGA TCCATGCTGCTGCGATCTGGGAGTG-3'

[0030] Pgpd-Eco V-R 5'-CCATGG GATATC TGTGACTGATCTGGTGTTGTTCTGA-3'

[0031] According to the nucleotide sequences of MDH, HPS and PHI, the following primers were respectively designed to construct the corr...

Embodiment 2

[0055] Recombinant Strain M-R2 Utilizes Methanol to Produce Oil

[0056] The oleaginous yeast R. toruloides CGMCC 2.1389 was purchased from China General Microorganism Culture Collection and Management Center. The recombinant strain M-R2 is an R. toruloides strain co-overexpressing MDH3, HPS and PHI, and its construction process is basically the same as in Example 1. The difference lies in the selection of methanol dehydrogenase MDH3 during the construction of M-R2.

[0057] According to the nucleotide sequence of MDH3, the following primers were respectively designed to construct the corresponding constitutive expression vector pZPK-GDP-MDH3 (the underlined part with EcoR V in the primer name is the EcoR V restriction site, and the primer name with The underlined part of SpeI is the SpeI restriction site):

[0058] The specific primers used to clone MDH3 are:

[0059] MDH3-EcoR V-F 5’-CCATGG GATATC ATGAAGAACACCCAGTCGGC-3'

[0060] MDH3-Spe I-R 5'-GG ACTAGT CTACTTGATGA...

Embodiment 3

[0075] Recombinant Strain M-R3 Utilizes Methanol to Produce Oil

[0076] The oleaginous yeast R. toruloides CGMCC 2.1389 was purchased from China General Microorganism Culture Collection and Management Center. The recombinant strain M-R3 is an R. toruloides strain co-overexpressing MDH3ACT, HPS and PHI, and its construction process is basically the same as in Example 1. The difference is that methanol dehydrogenase MDH3-ACT with activator protein is expressed during the construction of M-R2.

[0077] According to the nucleotide sequence of MDH3-ACT, the following primers were respectively designed to construct the corresponding constitutive expression vector pZPK-GDP-MDH3 (the underlined part with EcoR V in the primer name is the EcoR V restriction site, and the primer name in The underlined part with SpeI is the SpeI restriction site):

[0078] The specific primers used for cloning MDH3 are: MDH3-EcoR V-F and MDH3-ACT-Spe I-R, wherein

[0079] MDH3-ACT-Spe I-R 5'-GG ACTA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com