A kind of carbon fiber reinforced alloy composite material and preparation method thereof

A composite material and carbon fiber technology, used in mechanical equipment, pipes, pipes/pipe joints/fittings, etc., can solve the problems of high temperature corrosion resistance and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing a carbon fiber reinforced alloy composite material according to the above technical solution, including:

[0051] a) Vacuum melting the alloy to obtain a melt;

[0052] b) adding carbon fiber into the melt by hot extrusion to obtain a carbon fiber reinforced alloy composite material.

[0053] In the present invention, the temperature of step a) vacuum smelting is 1100~1600°C;

[0054] Step a) The vacuum degree of vacuum smelting is 40-60 Pa.

[0055] In terms of mass percentage, the mass of the carbon fiber is 0.02%-0.08% of the carbon fiber reinforced alloy composite material.

[0056] In the present invention, the addition of elements such as Cr and Mo in the alloy can use a master alloy. Vacuum smelting is specifically vacuum induction smelting. Step b) adding carbon fiber to the melt and adopting a hot extrusion process to obtain a carbon fiber reinforced alloy composite material. The alloy is subjected t...

Embodiment 1

[0060] Weigh 707.44 g of pure iron ingot, 12.4 g of chromium ingot, 0.1 g of molybdenum alloy, 10 g of pure aluminum ingot, 250 g of pure nickel ingot, 5 g of pure titanium ingot, 5 g of pure niobium ingot, 3 g of silicon nitride (Si 3 N 4 ), 0.2 g pure cobalt, 0.2 g pure copper block, 0.1 g pure silicon powder and 4.06 g rare earth (including 0.5 g neodymium, 0.01 g lanthanum, 0.05 g praseodymium, 0.5 g yttrium, 3 g vanadium), and prepare materials.

[0061] The metal raw materials in the preparation are smelted, and the smelting method is vacuum induction smelting. After the metal raw materials are put into the furnace, vacuum the entire furnace to ensure that the smelting process is carried out under vacuum; heat the furnace temperature to the range of 1100~1600°C, and stir properly to ensure that all the metal raw materials are melted and the components are evenly distributed; it should be noted that it can be According to the performance of each metal, the method of addi...

Embodiment 2

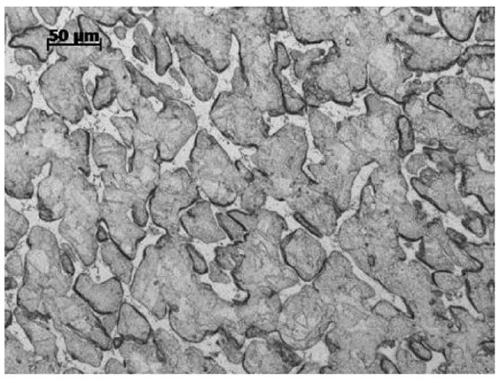

[0064] The carbon fiber reinforced alloy composite material prepared in Example 1 is carried out microscopic detection, such as figure 1 Shown is the metallographic micrograph of the carbon fiber reinforced alloy composite material prepared in Example 1 of the present invention.

[0065] Depend on figure 1 It can be seen that although the carbon fiber reinforced alloy composite material of the present invention adds more element types and higher element content, resulting in more substructures in the structure, it is still a ferritic alloy. Due to the addition of Nb and Ti, the carbon fiber reinforced alloy composite material of the present invention has a refined structure, which shows that the carbon fiber reinforced alloy composite material of the present invention has good mechanical properties. Chromium is the most basic element of heat-resistant steel, and can form a dense oxide film, so that the carbon fiber reinforced alloy composite material of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com