Silver/RGO (reduced graphene oxide) composite material prepared on basis of graphene oxide and preparation method of silver/RGO composite material

A composite material, graphene technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of reduced electrical and thermal conductivity, and achieve the effect of improving corrosion resistance, high thermal conductivity, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

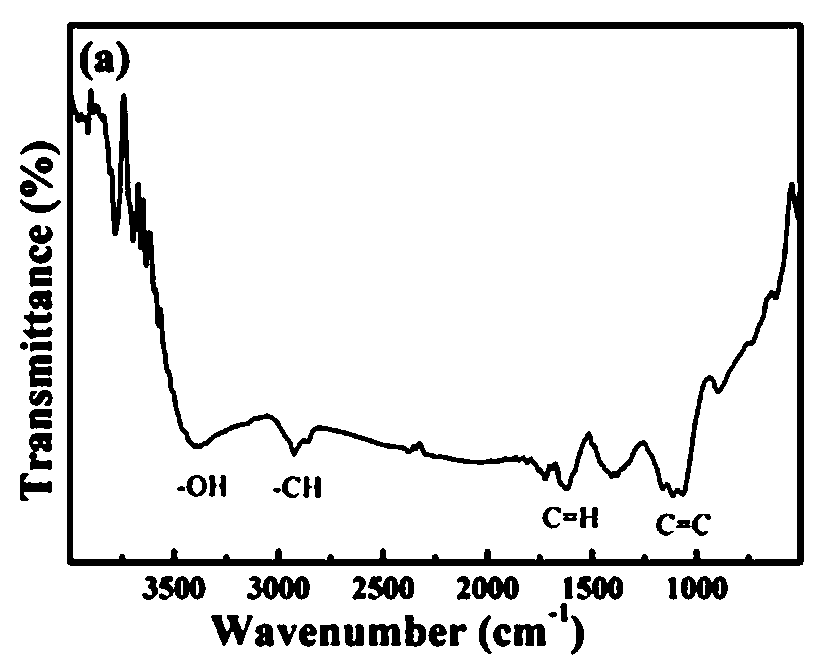

Image

Examples

Embodiment

[0040] A preparation method for preparing silver / reduced graphene oxide composite material based on graphene oxide, comprising the steps of:

[0041] 1) Degrease the aluminum substrate sample in a degreasing solution at 60°C for 5 minutes, and then clean the aluminum substrate sample with clean water. The degreasing solution in this example is: sodium carbonate 40g / L, trisodium phosphate 50g / L, OP-10 emulsifier 1.0g / L mixed solution;

[0042] 2) Activate the degreased sample in an activation solution at 25°C for 2 minutes, and wash it with clean water. The activation solution in this example is sodium hydroxide 40g / L;

[0043] 3) Dip the activated sample in a zinc dipping solution at 25°C for 1 minute, and clean it with clean water. The primary zinc dipping solution in this example is: sodium hydroxide 80g / L, trisodium citrate 12.5g / L, a mixture of zinc nitrate hexahydrate 25g / L, nickel chloride hexahydrate 12.5 g / L, ferric chloride hexahydrate 0.8g / L and thiourea 0.2g / L;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com