Composite surface structure friction pair

A technology of surface texture and surface friction, which is applied to rotating parts, bearings, and bearing components that resist centrifugal force, can solve problems such as unfavorable development trends, large environmental hazards, and impact on the service life of mechanical structures, achieving a wide range of applications and improving Excellent tribological properties and strong pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

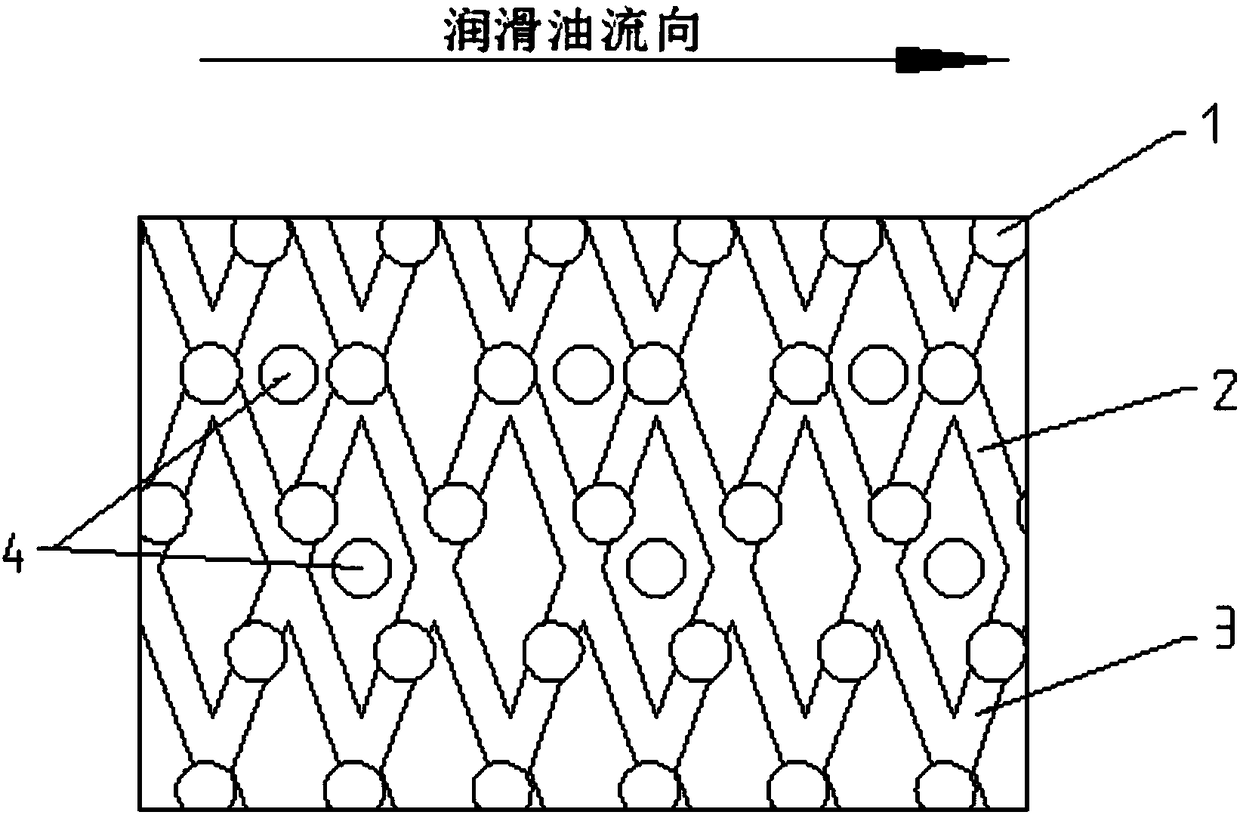

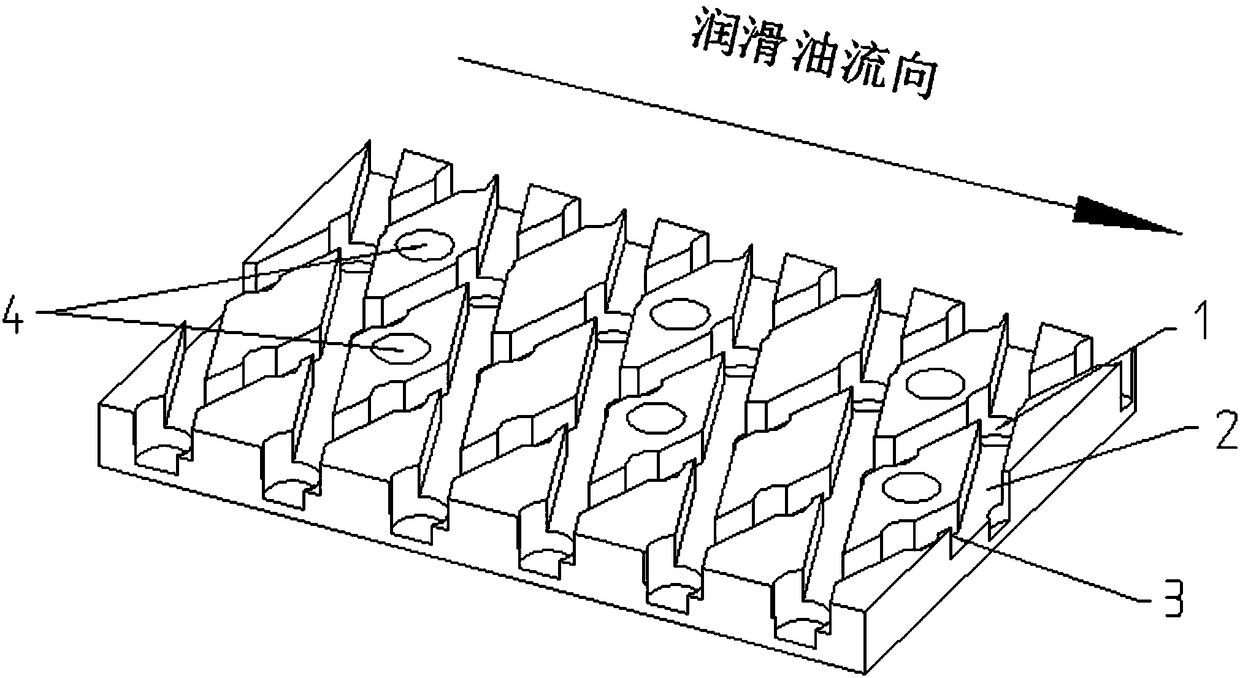

[0030] Taking YT15 alloy steel as an example, the laser processing method uses Libra-HE femtosecond laser, combined with figure 1 The preparation of the present invention will be described.

[0031] The embodiment of the present invention provides YT15 composite surface texture design and processing method, including the following steps:

[0032] Step 1. The surface of YT15 needs to undergo a pre-treatment process before laser processing. The pre-treatment first uses boron carbide advanced polishing materials to grind YT15, and the entire grinding process is carried out on frosted glass; then use a polishing machine to polish YT15, so that its The surface roughness value Ra is about 0.04 on the Mitutoyo SJ-410 surface roughness measuring instrument; finally, it is cleaned ultrasonically in acetone solution for 15-20 minutes.

[0033] Step 2, optimize the design of the surface texture of the moving friction pair, the design results are as follows figure 1 As shown; the groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com