Preparation method of aldehyde-free non-mildew non-combustible recombinant bamboo floor

A technology for recombining bamboo and flooring, applied in mechanical equipment, manufacturing tools, flat products and other directions, can solve the problems of easy mildew, contain formaldehyde, easy to burn, etc., and achieve a simple preparation method, easy-to-obtain raw materials, and good flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

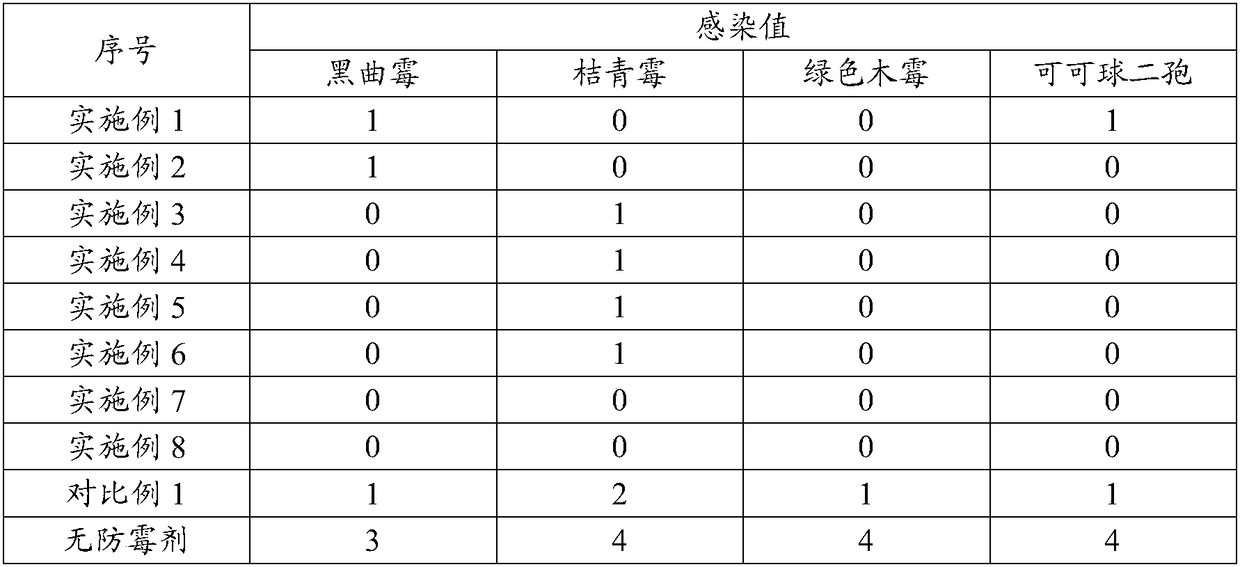

Examples

Embodiment 1

[0061] A preparation method of a Chinese herbal medicine antifungal agent is as follows: soak the Chinese herbal medicine in 70% ethanol solution, the mass ratio of the Chinese herbal medicine to ethanol is 1:5, heat up to 50°C, filter and remove the filter residue after heating for 120min, and obtain the Chinese herbal medicine concentration of 98.2mg / ml Chinese herbal antifungal agent;

[0062] The above-mentioned Chinese herbal medicine is composed of the following components in parts by weight: 20 parts of thyme, 50 parts of male clove, 15 parts of cinnamaldehyde and 10 parts of tangerine peel.

Embodiment 2

[0064] A preparation method of a Chinese herbal medicine antifungal agent is as follows: soak the Chinese herbal medicine in 40% ethanol solution, the mass ratio of the Chinese herbal medicine to ethanol is 1:20, heat up to 80° C., filter and remove the filter residue after heating for 30 minutes, and obtain the Chinese herbal medicine concentration of 52.7mg / ml Chinese herbal antifungal agent;

[0065] The above-mentioned Chinese herbal medicine is composed of the following components in parts by weight: 30 parts of thyme, 60 parts of male clove, 10 parts of cinnamaldehyde and 5 parts of tangerine peel.

Embodiment 3

[0067] A preparation method of a nano-silver-zinc composite antifungal agent is as follows: Weigh 75 parts of zinc acetate, 15 parts of anhydrous sodium carbonate, 5 parts of silver nitrate and 10 parts of sodium dodecylbenzenesulfonate, and grind them in a mortar Mix evenly, then wash with deionized water and absolute ethanol respectively, filter and dry, and then put it into a high-temperature roasting furnace for sintering at a temperature of 250-500°C to obtain a nano-silver-zinc composite antifungal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com