Method for producing graphene film through microwave combined sol-gel technology

A technology of graphene film and sol, which is applied in the field of nanomaterials, can solve problems such as complex process, influence of graphene film performance, film conductivity, etc., and achieve the effect of simple process, excellent thermal conductivity and hydrophobicity, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

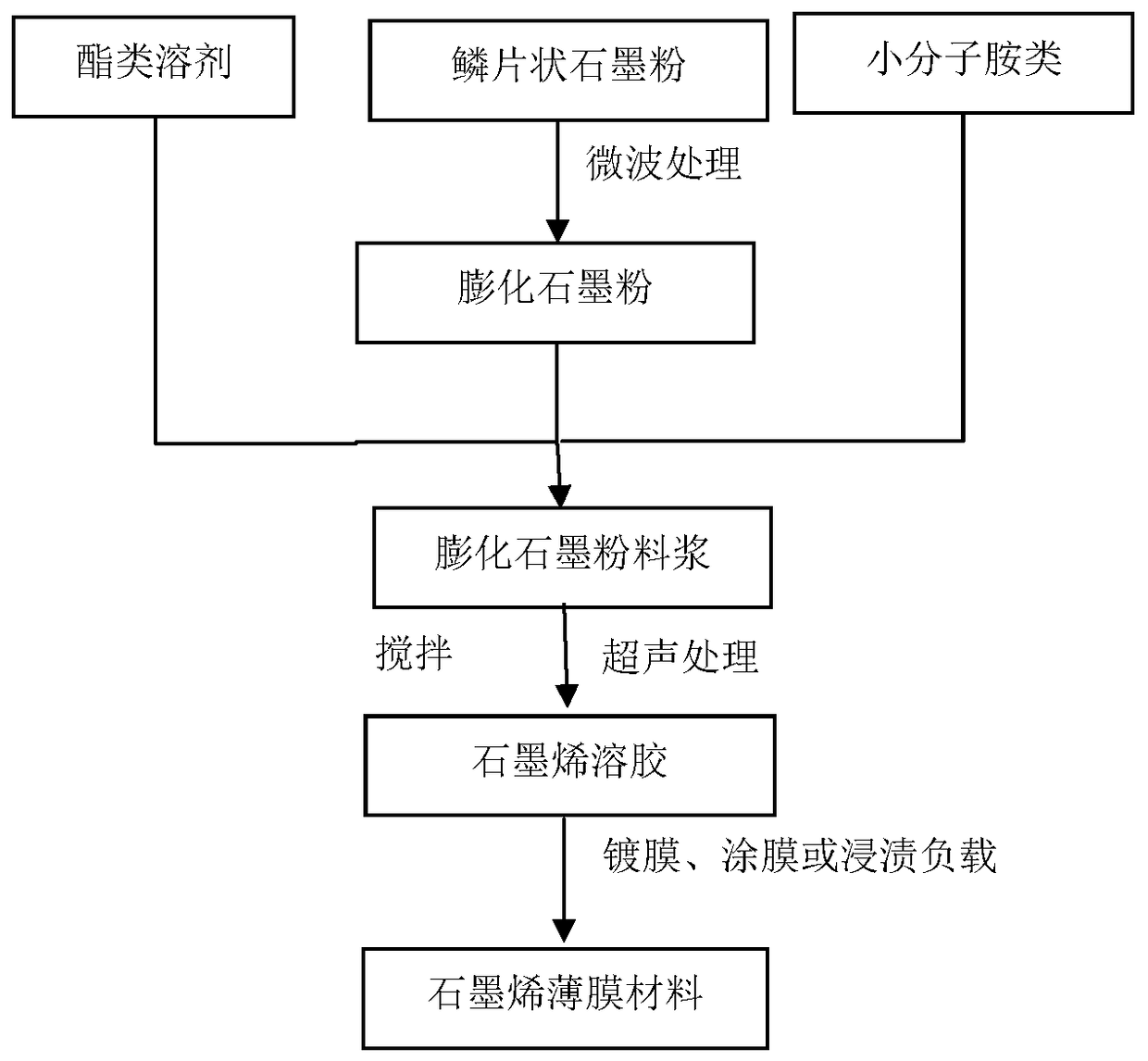

Method used

Image

Examples

Embodiment 1

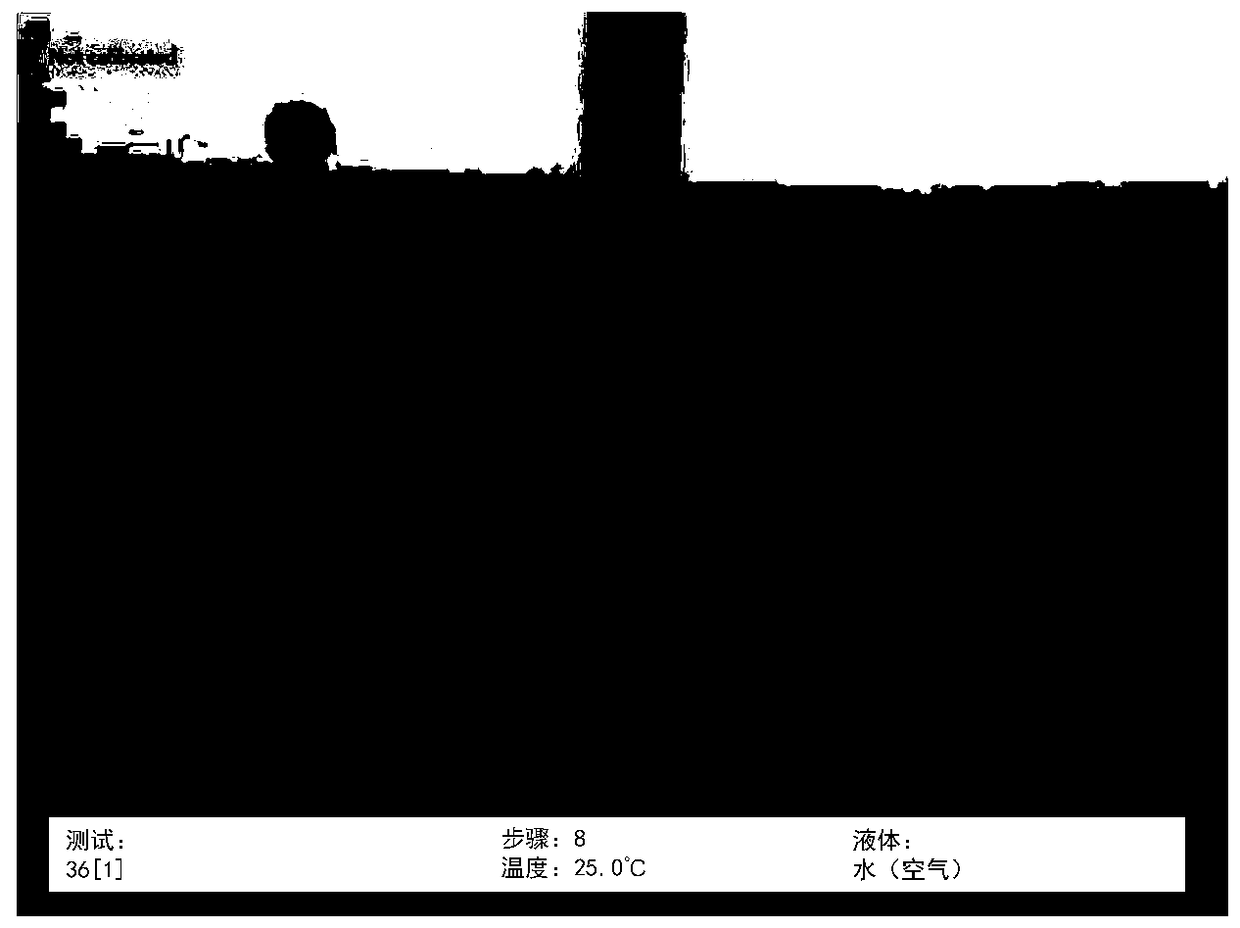

[0036]Put 0.2 g of flake graphite powder into a microwave oven, and use 350W power microwave to expand for 30 minutes to obtain expanded flake graphite powder. Mixed dibasic acid ester (DBE) was selected as the solvent, and dimethylamine was used as the intercalation agent. Take 0.2g of expanded graphite powder, add 200mL of mixed dibasic acid ester (DBE) and 15mL of dimethylamine, and process at 40KHz ultrasonic frequency for 240min to obtain graphene sol, aging at room temperature for 12h, and coating on glass substrate by dipping and pulling , and finally dried at 60°C for 6h to prepare a graphene film. The thickness of the graphene film was measured to be 20.5 μm. The measured wetting angle of the film is 110.6°, as Figure 4 shown.

Embodiment 2

[0038] Put 0.2 g of flake graphite powder into a microwave oven, and expand it for 3 minutes by using a microwave with a power of 3000W to obtain expanded flake graphite powder. Ethyl acetate was selected as the solvent, and monomethylamine was used as the intercalation agent. Take 0.2g of expanded graphite powder, add 100mL of ethyl acetate and 3mL of monomethylamine, and process it at an ultrasonic frequency of 25KHz for 360min to obtain a graphene sol, age at 80 for 2h, immerse the melamine foam in the sol for 2h, remove the sol, and finally Dry at 80°C for 4 hours to prepare a graphene film. The measured wetting angle of the film is 137°, as Figure 5 shown.

Embodiment 3

[0040] Put 0.2 g of flake graphite powder into a microwave oven, and use 1000W power microwave to expand for 10 minutes to obtain expanded flake graphite powder. Methyl acetate was selected as the solvent, and diethanolamine was used as the intercalation agent. Take 0.2g of expanded graphite powder, add 80mL of ethyl acetate and 12mL of monomethylamine, and process it at an ultrasonic frequency of 68KHz for 30min to obtain a graphene sol, age at room temperature for 72h, immerse the melamine foam in the sol for 4h, remove the sol, and finally Dry at 40°C for 10 h to prepare a graphene film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com