Method for synthesizing amide type gemini quaternary ammonium salt surfactant

A technology of gemini quaternary ammonium salt and surfactant, which is applied in the field of synthesis of amide type gemini quaternary ammonium salt surfactant, can solve the problems of poor durability of corrosion inhibition film, high use concentration, and inability to take into account, and achieve simple and easy reaction , high surface activity and excellent corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The synthetic method of the amide type gemini quaternary ammonium salt surfactant provided by the present embodiment comprises the following steps carried out in order:

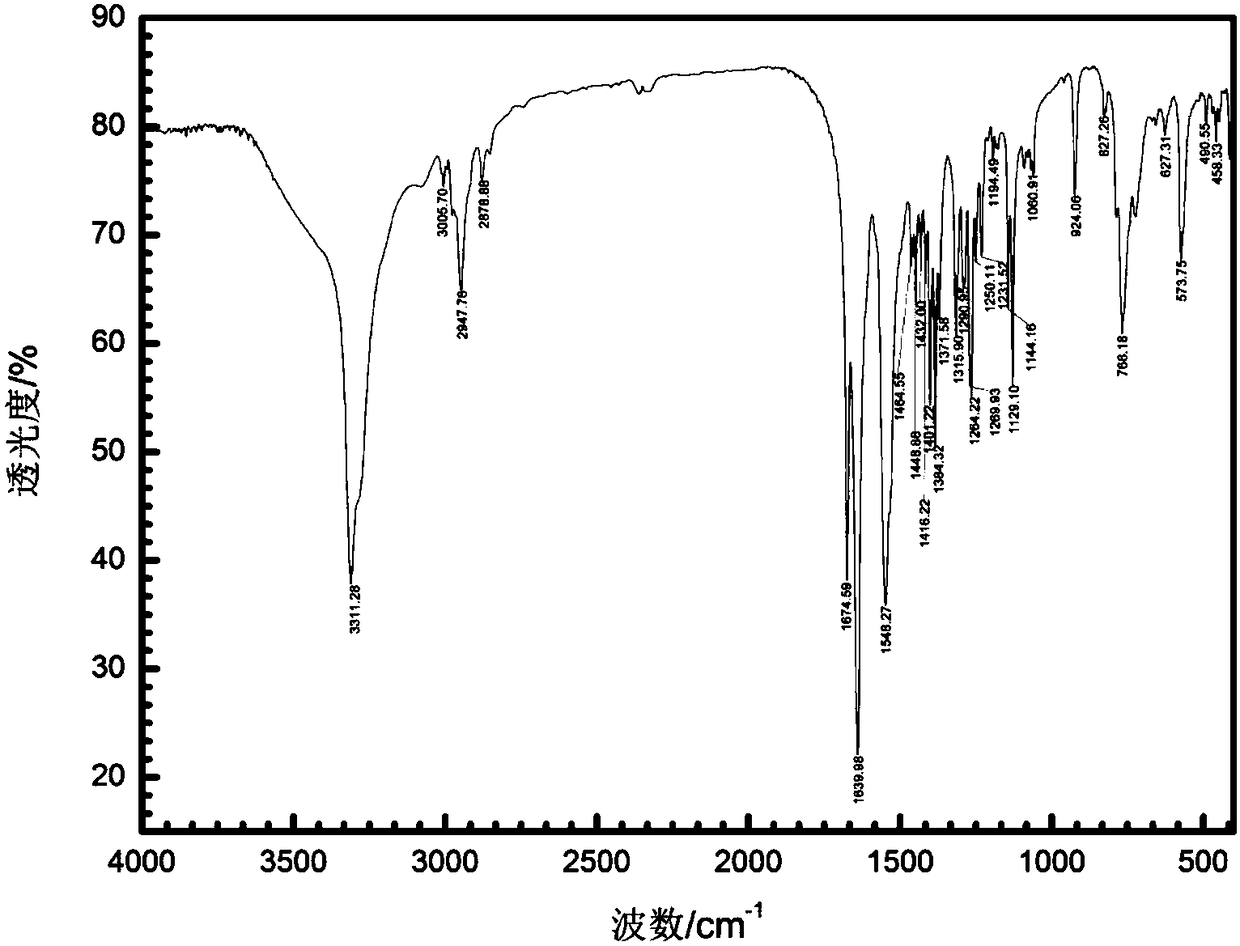

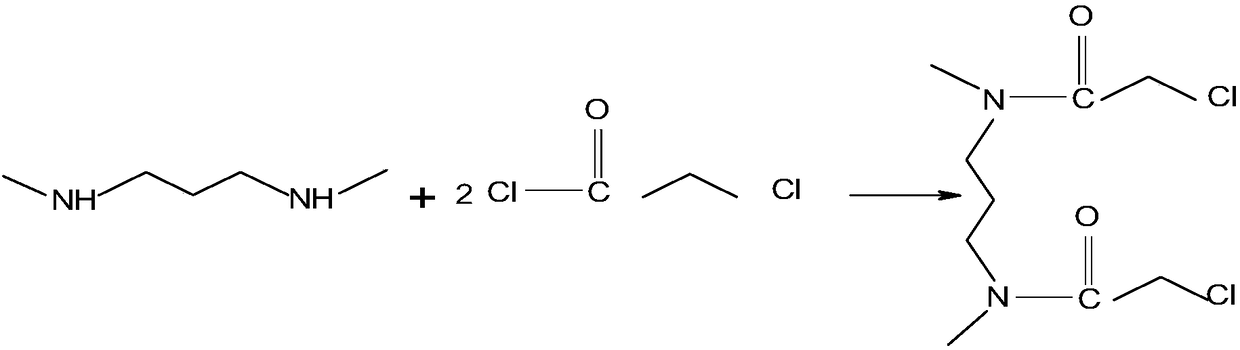

[0019] 1) Preparation of intermediate: add 50ml of dichloromethane into a beaker, dissolve 11.3g of chloroacetyl chloride in dichloromethane, take 3.7g of 1,3-propanediamine, and mix it in every 5 Slowly drip into the beaker at a rate of one drop per second. After the dropwise addition is complete, raise the temperature and react in a water bath at 35°C for 4 hours, and then evaporate under reduced pressure with a rotary evaporator in a water bath at 60°C for 1 hour to remove the solvent and excess chlorine. Acetyl chloride, the residue was dissolved in water, filtered, and then recrystallized once with absolute ethanol to obtain 4.7 g of an intermediate, namely 1,3-bis(2-chloroacetamide)propylamine.

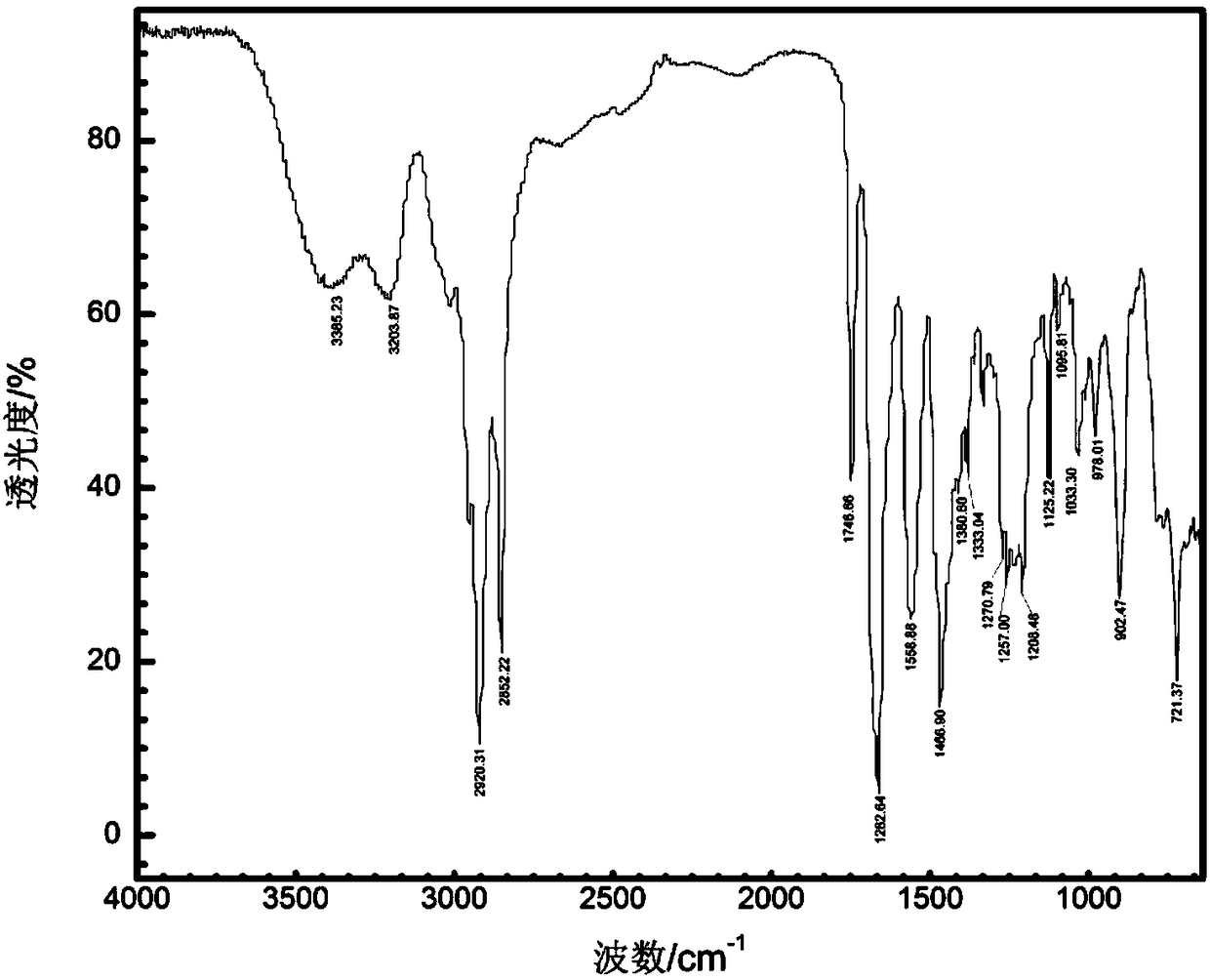

[0020] 2) Synthesis of amide-type gemini quaternary ammonium salt surfactant: 4.7 g of 1,3-bis(2-chlo...

Embodiment 2

[0022] The synthetic method of the amide type gemini quaternary ammonium salt surfactant provided by the present embodiment comprises the following steps carried out in order:

[0023] 1) Preparation of intermediate: add 50ml of dichloromethane into a beaker, dissolve 14.1g of chloroacetyl chloride in dichloromethane, take 3.7g of 1,3-propanediamine, and mix in ice bath and stirring at every 5 Slowly drip into the beaker at a rate of one drop per second. After the dropwise addition is completed, raise the temperature and react in a water bath at 35°C for 5 hours, and then use a rotary evaporator in a water bath at 60°C for 1.5 hours to remove the solvent and excess chlorine. Acetyl chloride, the residue was dissolved in water, filtered, and then recrystallized once with absolute ethanol to obtain 4.9 g of an intermediate, namely 1,3-bis(2-chloroacetamide)propylamine.

[0024] 2) Synthesis of amide-type gemini quaternary ammonium salt surfactant: 4.9 g of 1,3-bis(2-chloramide) ...

Embodiment 3

[0026] The synthetic method of the amide type gemini quaternary ammonium salt surfactant provided by the present embodiment comprises the following steps carried out in order:

[0027] 1) Preparation of intermediate: add 50ml of dichloromethane into a beaker, dissolve 17.0g of chloroacetyl chloride in dichloromethane, take 3.7g of 1,3-propanediamine, and mix it in every 5 Slowly drip into the beaker at a rate of one drop per second. After the dropwise addition is completed, raise the temperature and react in a water bath at 35°C for 6 hours, then evaporate under reduced pressure with a rotary evaporator in a water bath at 60°C for 2 hours to remove the solvent and excess chlorine. Acetyl chloride, the residue was dissolved in water, filtered, and then recrystallized once with absolute ethanol to obtain 5.0 g of an intermediate, namely 1,3-bis(2-chloroacetamide)propylamine.

[0028] 2) Synthesis of amide type gemini quaternary ammonium salt surfactant: 5.0 g of 1,3-bis(2-chloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com