High-efficiency separation and purification method for pneumocandin

A technology of separation and purification, nemocontin, applied in the direction of peptides, etc., can solve the problems of difficult environmental control, low process efficiency, low sample load, etc., to solve the problems of insufficient selectivity, good repeatability, and fast separation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

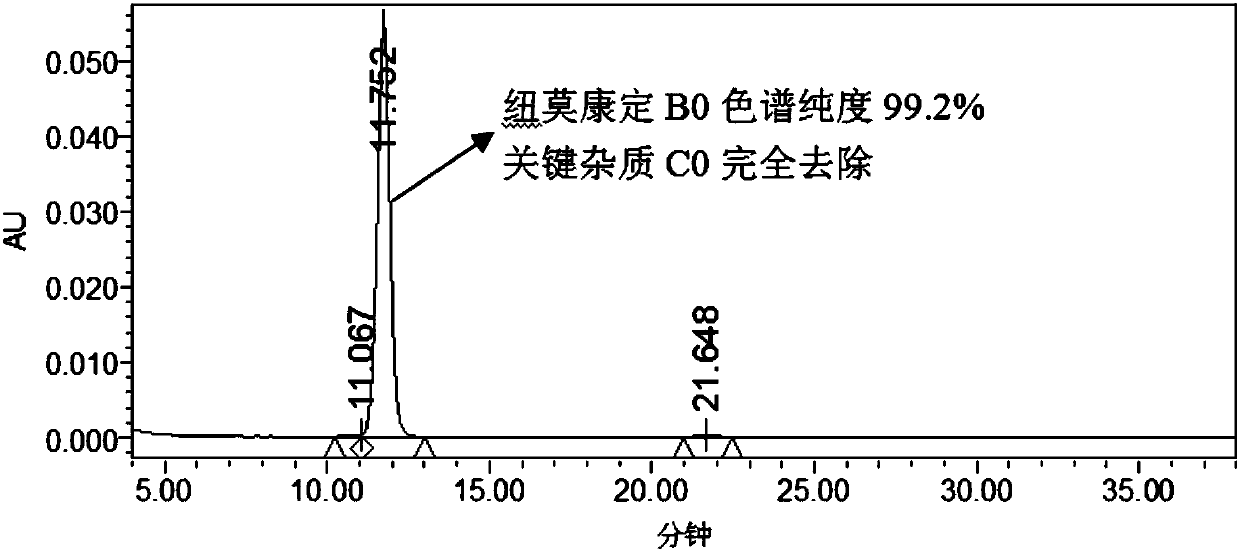

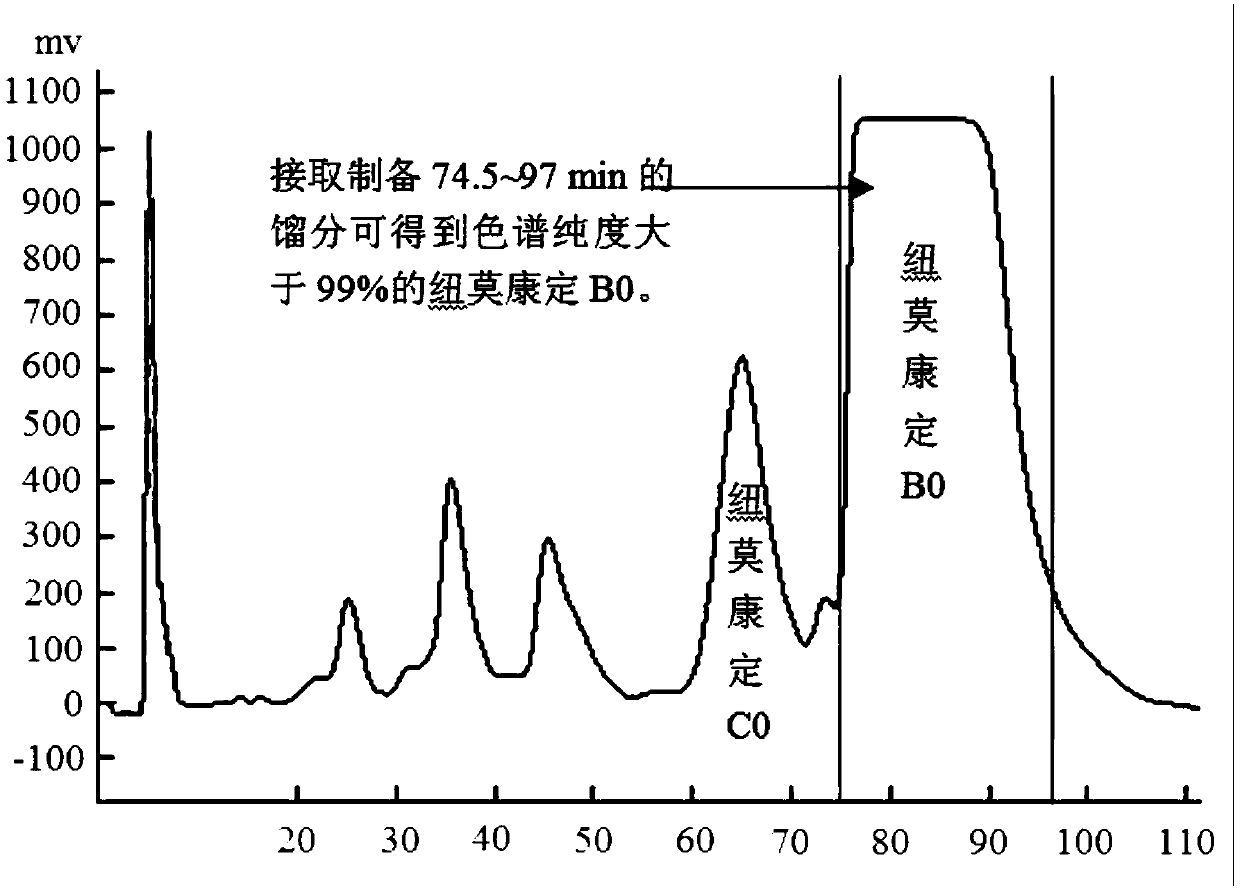

[0030] Neomocontin crude product 3g, be dissolved in 30mL ethanol-water, sample volume 30mL, load sample volume 1%; Use the hydrophilic silica gel column (column specification 50 * 250mm, particle size 10 μm, aperture Packing mass 300g), flow rate 80mL / min; organic solvent is ethanol, wherein the volume ratio of organic solvent / water is 90 / 10; ultraviolet detector, detection wavelength 210nm, from the target peak out of the peak start to receive fractions until the peak returns to the baseline stop , after purification, a product with a purity of more than 99.1% of nemocontinin B0 and an impurity C0 of less than 0.1% can be obtained.

Embodiment 2

[0032] Other conditions are identical with embodiment 1, and difference is that filler aperture is After purification, a product with a purity of more than 99.8% of pneumocidine B0 and an impurity C0 of less than 0.1% can be obtained.

Embodiment 3

[0034] Other conditions are identical with embodiment 1, and difference is to use carboxyl hydrophilic silica gel column (column specification 50 * 1000mm, particle diameter 10 μ m, pore diameter Filler quality 1.2kg), can obtain the product of pneumocidine B0 purity more than 99.5% after purification, impurity C0 less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com