A kind of graphene modified corn stalk core composite electromagnetic shielding film and preparation method thereof

A graphene modification, corn stalk technology, applied in the direction of graphene, chemical instruments and methods, nano carbon, etc., can solve the problems of complicated preparation process and high price, achieve the effect of wide source of materials, reduce dosage, and solve processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

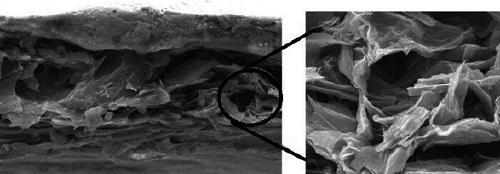

Image

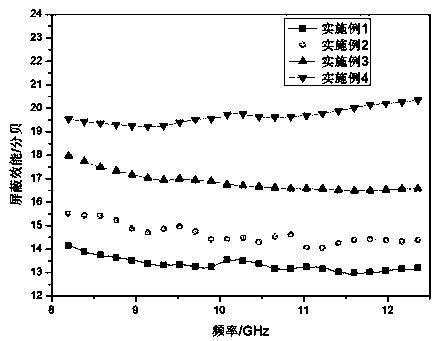

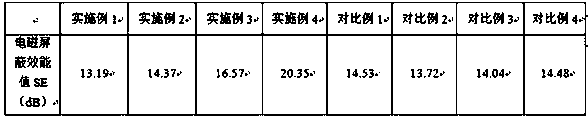

Examples

Embodiment 1

[0035] A composite electromagnetic shielding film prepared by the following steps:

[0036] (1) Corn stalk pretreatment

[0037] After the corn stalks are peeled off the stalk skin, the corn stalk cores are taken, dried in vacuum at 60°C for 2 hours, pulverized, and passed through a 100-mesh sieve to obtain the straw core powder; then the straw core powder is mixed with ZnCl 2 The aqueous solution is mixed at a mass ratio of 1:1, stirred in a water bath at 75°C for 1 hour, then suction filtered, washed with water, and dried at 40°C to obtain activated straw cores;

[0038] (2) Preparation of hybrid materials

[0039] a. Take the activated straw core powder prepared in step (1) and disperse it in water, the dispersion concentration is 0.1g / mL, stir at a speed of 150rpm, and stir for 10min to obtain a uniformly dispersed straw core powder suspension;

[0040] b. Add dropwise an aqueous solution of graphene oxide with a solid content of 10 mg / g to the suspension of straw core ...

Embodiment 2

[0051] A composite electromagnetic shielding film prepared by the following steps:

[0052] (1) Corn stalk pretreatment

[0053] After the corn stalks are peeled off the stalk skin, the corn stalk cores are taken, dried in vacuum at 60°C for 2 hours, pulverized, and passed through a 100-mesh sieve to obtain the straw core powder; then the straw core powder is mixed with ZnCl 2 The aqueous solution is mixed according to the mass ratio of 1:1.2, stirred in a water bath at 75°C for 1 hour, then suction filtered, washed with water, and dried at 40°C to obtain activated straw cores;

[0054] (2) Preparation of hybrid materials

[0055] a. Take the activated straw core powder prepared in step (1) and disperse it in water, the dispersion concentration is 0.1g / mL, stir at a speed of 150rpm, and stir for 10min to obtain a uniformly dispersed straw core powder suspension;

[0056] b. Add dropwise an aqueous solution of graphene oxide with a solid content of 10 mg / g to the straw core ...

Embodiment 3

[0067] A composite electromagnetic shielding film prepared by the following steps:

[0068] (1) Corn stalk pretreatment

[0069] After the corn stalks are peeled off the stalk skin, the corn stalk cores are taken, dried in vacuum at 60°C for 2 hours, pulverized, and passed through a 100-mesh sieve to obtain the straw core powder; then the straw core powder is mixed with ZnCl 2 The aqueous solution is mixed according to the mass ratio of 1:1.4, stirred in a water bath at 75°C for 1 hour, then suction filtered, washed with water, and dried at 40°C to obtain activated straw cores;

[0070] (2) Preparation of hybrid materials

[0071] a. Take the activated straw core powder prepared in step (1) and disperse it in water, the dispersion concentration is 0.1g / mL, stir at a speed of 150rpm, and stir for 10min to obtain a uniformly dispersed straw core powder suspension;

[0072] b. Add dropwise an aqueous solution of graphene oxide with a solid content of 10 mg / g to the straw core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com