Method of preparing perovskite nanocrystalline film by spraying

A nanocrystal and perovskite technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of uneven film, inability to evaporate to dryness quickly, poor solution stability, etc. Film speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) CsPbBr 3 Quantum dots were dispersed into n-hexane to obtain CsPbBr at a concentration of 0.5 mg / mL 3 Quantum dot dispersion;

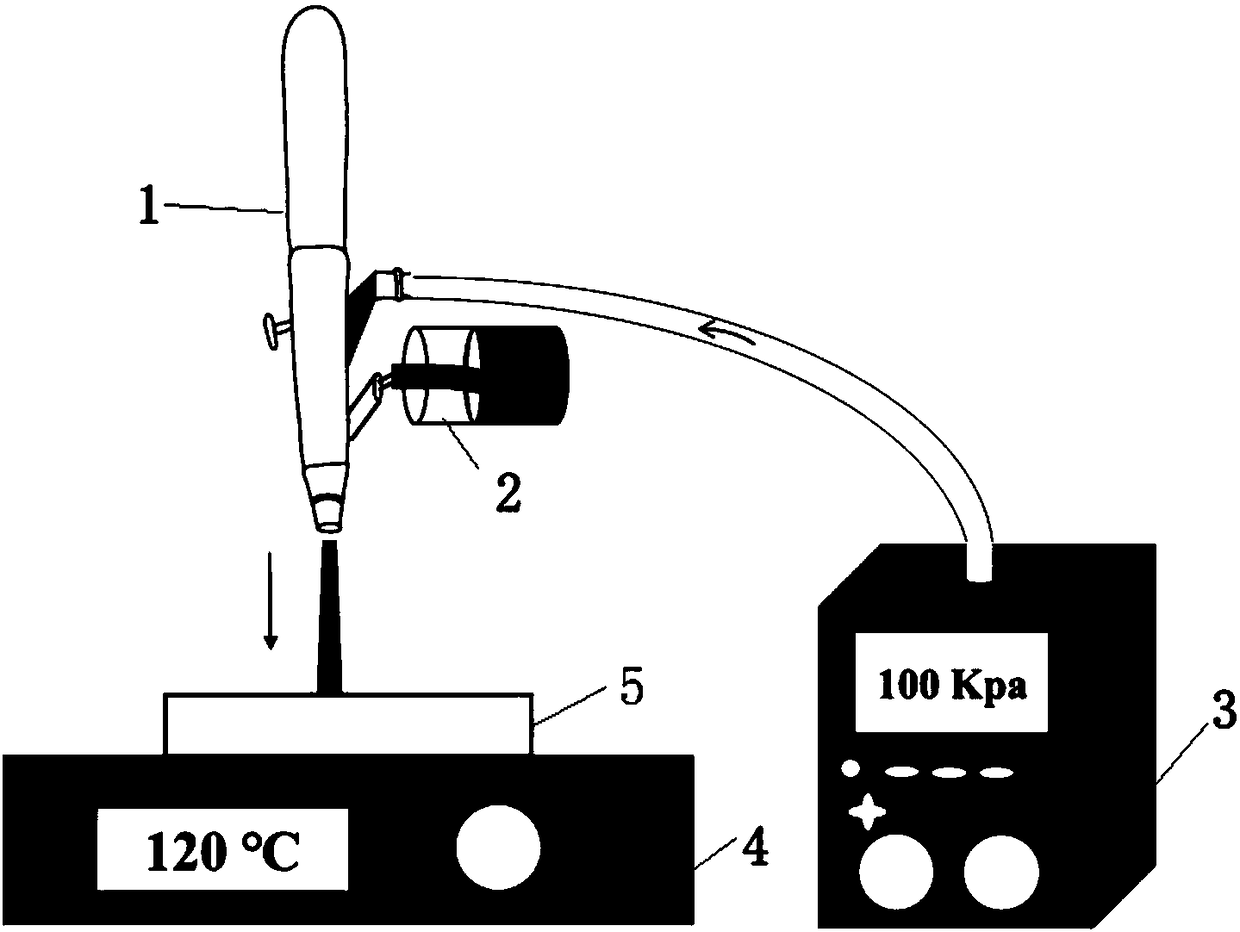

[0031] 2) CsPbBr 3 Put the quantum dot dispersion into a spray bottle and install it on the spray gun. The base area is 2×2cm 2 , adjust the distance between the spray gun and the horizontally placed glass substrate to be 4cm, through EFD's Ultimus TM The I dispensing platform can precisely control the air pressure to 100Kpa, and the liquid output of the spray gun is 0.02mL / s;

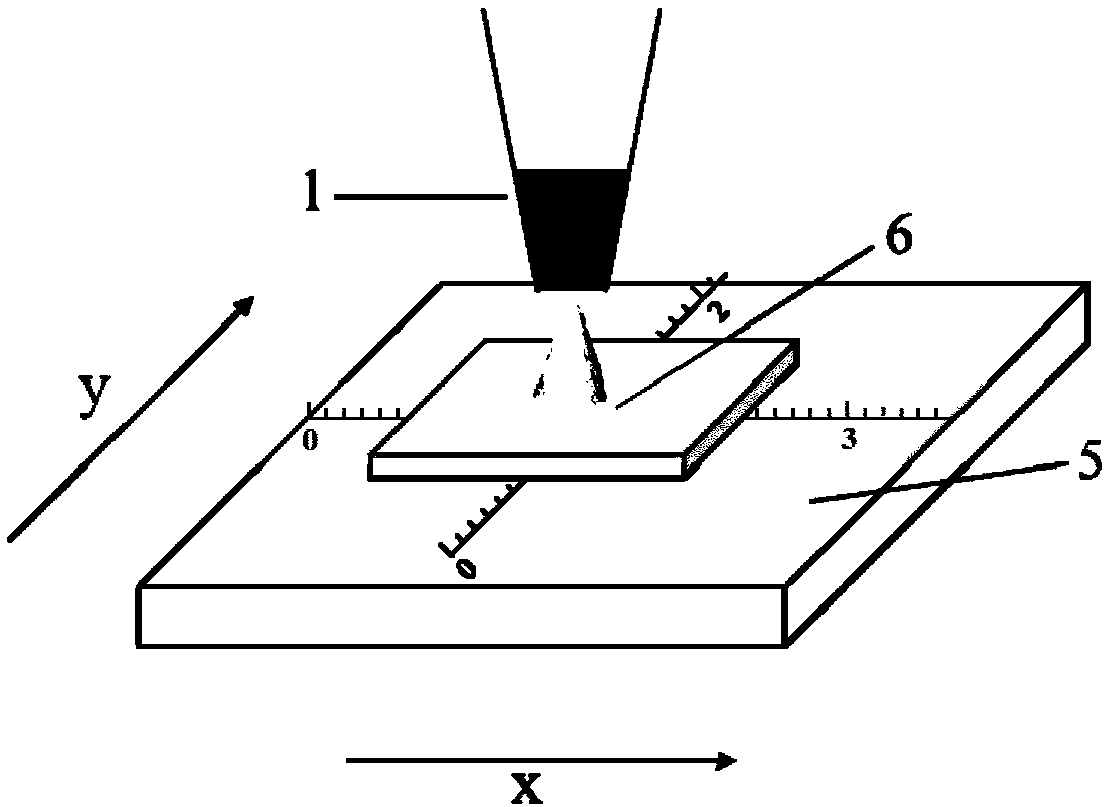

[0032] 3) Move the substrate on the horizontal displacement stage at a constant speed, and spray at 25°C for 30s;

[0033] 4) CsPbBr 3 The quantum dot film was annealed on a hot stage at 90° C. for 15 minutes to obtain a perovskite nanocrystalline film.

Embodiment 2

[0035] 1) CsPbBr 3 Quantum dots were dispersed into n-hexane to obtain CsPbBr at a concentration of 0.5 mg / mL 3 Quantum dot dispersion;

[0036] 2) CsPbBr 3 Put the quantum dot dispersion into a spray bottle and install it on the spray gun. The base area is 2×2cm 2 , adjust the distance between the spray gun and the horizontally placed silicon wafer substrate to be 4cm, through EFD's Ultimus TM The I dispensing platform can precisely control the air pressure to 100Kpa, and the liquid output of the spray gun is 0.02mL / s;

[0037] 3) After heating the substrate to 60°C, move the substrate on the horizontal displacement stage at a constant speed, and spray for 30s;

[0038] 4) CsPbBr 3 The quantum dot film was annealed on a hot stage at 90 °C for 15 min.

Embodiment 3

[0040] 1) CsPbBr 3 Quantum dots were dispersed into n-hexane to obtain CsPbBr at a concentration of 0.5 mg / mL 3 Quantum dot dispersion;

[0041] 2) CsPbBr 3 Put the quantum dot dispersion into a spray bottle and install it on the spray gun. The base area is 2×2cm 2 , adjust the distance between the spray gun and the horizontally placed PET substrate to be 4cm, through EFD's Ultimus TM The I dispensing platform can precisely control the air pressure to 100Kpa, and the liquid output of the spray gun is 0.02mL / s;

[0042]3) After heating the substrate to 90°C, move the substrate on the horizontal displacement stage at a constant speed, and spray for 30s;

[0043] 4) CsPbBr 3 The quantum dot film was annealed on a hot stage at 90 °C for 15 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com