Iron modified sheet type ZSM-5 zeolite catalyst preparation method

A ZSM-5, zeolite catalyst technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of difficult propagation, low hydrothermal stability, impossible industrial synthesis, etc., to achieve strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Activating the aluminum source with an inorganic base.

[0044] 2g Al 2 O 3 Powder (pseudo-boehmite) was dispersed in 100g deionized water, then 2g NaOH solid was added and stirred and fully hydrolyzed at room temperature for 2 hours to make B solution;

[0045] (2) Synthesis of ZSM-5 zeolite with activated aluminum source.

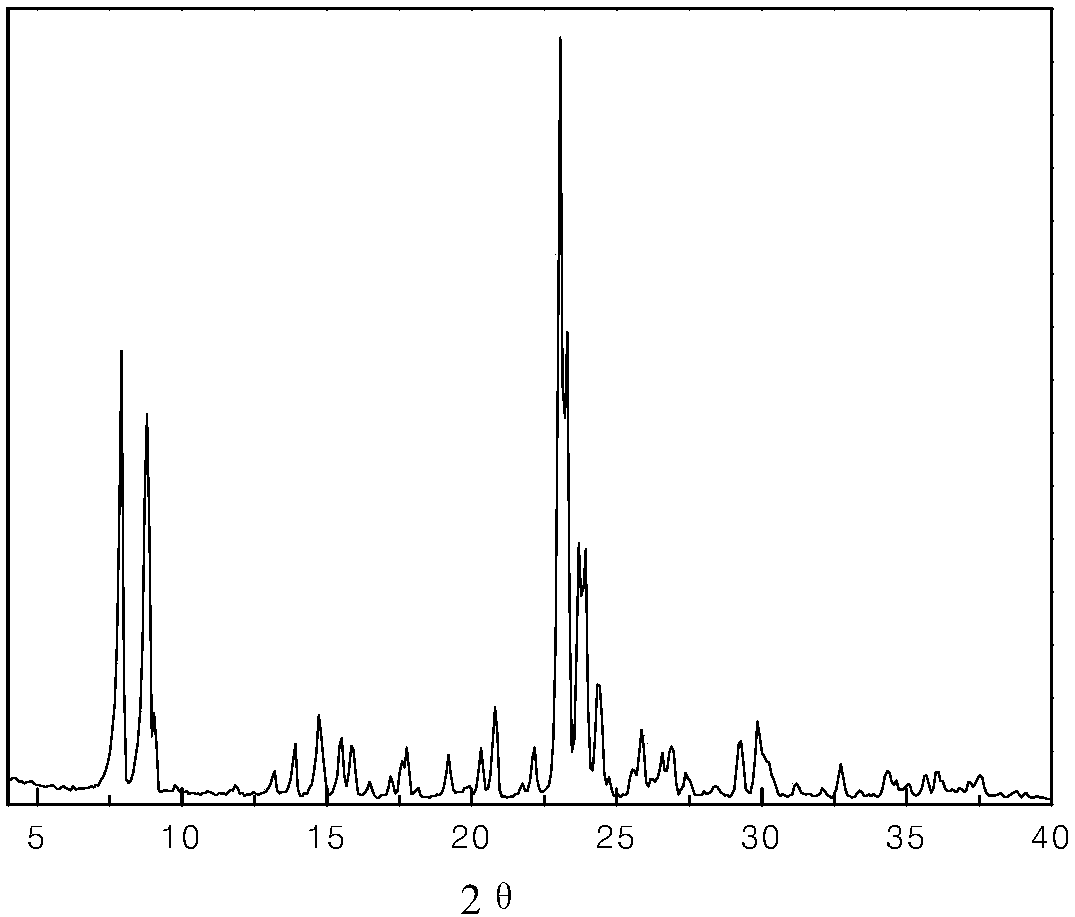

[0046] 100g of silica sol (industrial grade, SiO 2 ≥30wt%) dispersed in 100g of deionized water, then added 18g of n-butylamine solution (industrial grade), fully stirred at room temperature for 1 hour to make A solution; the B solution obtained by activation was slowly added dropwise to A under stirring In the solution, a uniform gel C was prepared; 2% of the micron iron powder was added to the gel C and stirred uniformly. The gel mixture has the following molar composition: SiO 2 / Al 2 O 3 =25, Na 2 O / SiO 2 =0.05, NBA / SiO 2 =0.5, H 2 O / SiO 2 =30. The prepared gel was transferred to a synthesis kettle, crystallized at 170° C. for ...

Embodiment 2

[0048] (1) Activating the aluminum source with an inorganic base.

[0049] 2g Al 2 O 3 Powder (pseudo-boehmite) was dispersed in 100g deionized water, then 2g NaOH solid was added and stirred and fully hydrolyzed at room temperature for 2 hours to make B solution;

[0050] (2) Synthesis of ZSM-5 zeolite with activated aluminum source.

[0051] 100g of silica sol (industrial grade, SiO 2 ≥30wt%) dispersed in 100g of deionized water, then added 18g of n-butylamine solution (industrial grade), fully stirred at room temperature for 1 hour to make A solution; the B solution obtained by activation was slowly added dropwise to A under stirring In the solution, a uniform gel C was prepared; 8% of the micron iron powder was added to the gel C and stirred uniformly. The gel mixture has the following molar composition: SiO 2 / Al 2 O 3 =25, Na 2 O / SiO 2 =0.05, NBA / SiO 2 =0.5, H 2 O / SiO 2 =30. The prepared gel was transferred to a synthesis kettle, crystallized at 170° C. for ...

Embodiment 3

[0053] (1) Activating the aluminum source with an inorganic base.

[0054] 2g Al 2 O 3 Powder (pseudo-boehmite) was dispersed in 100g deionized water, then 2g NaOH solid was added and stirred and fully hydrolyzed at room temperature for 2 hours to make B solution;

[0055] (2) Synthesis of ZSM-5 zeolite with activated aluminum source.

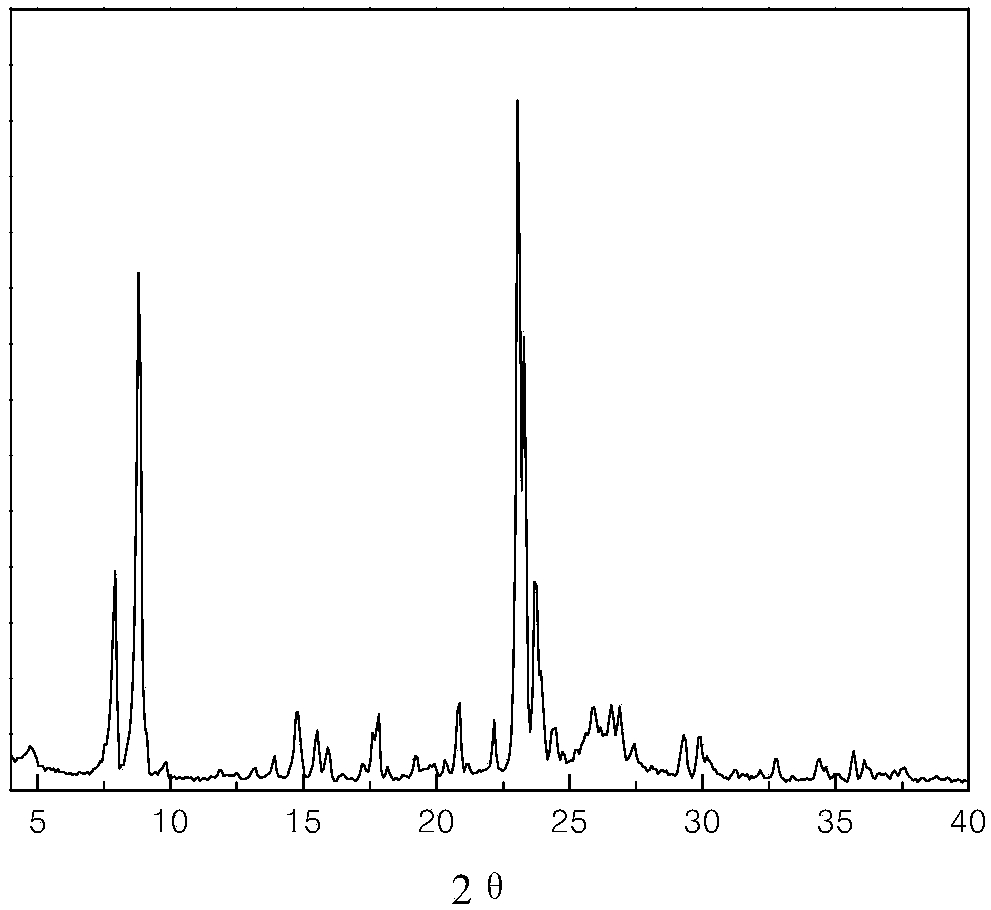

[0056] 100g of silica sol (industrial grade, SiO 2 ≥30wt%) dispersed in 100g of deionized water, then added 18g of n-butylamine solution (industrial grade), fully stirred at room temperature for 1 hour to make A solution; the B solution obtained by activation was slowly added dropwise to A under stirring In the solution, a homogeneous gel C was prepared; 2% of the total mass of nano iron powder was added to the gel C and stirred uniformly. The gel mixture has the following molar composition: SiO 2 / Al 2 O 3 =25, Na 2 O / SiO 2 =0.05, NBA / SiO 2 =0.5, H 2 O / SiO 2 =30. The prepared gel was transferred to a synthesis kettle, crystallized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com