Temperature-control hot-gas bypass automatic-backflow continuous-defrosting plate ice heat pump

A hot gas bypass and automatic return technology, applied in heat pumps, fluid circulation arrangements, lighting and heating equipment, etc., can solve the problem of affecting the deicing performance of the evaporator, increasing the configuration cost and energy consumption, and reducing the heating capacity of the unit Improve ice-making heating capacity and operating efficiency, reduce investment cost and operating cost, and prevent local surface temperature from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

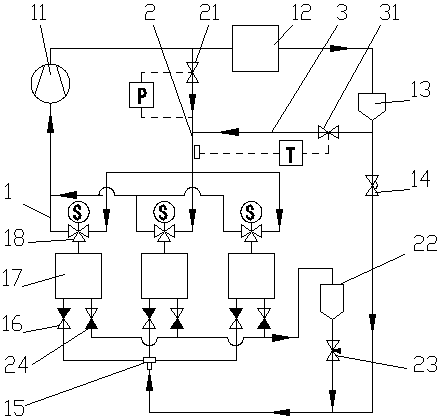

[0011] Example: see figure 1 , a temperature-controlled hot gas bypass automatic return continuous defrosting plate ice heat pump, including a heating main circulation system, a hot gas bypass branch 2 and a liquid return branch 3; it also includes conventional supporting components of a refrigeration system connected in the system , pipelines, valves, and detection and control systems; three sets of heat exchangers are connected in parallel, and three three-way valves 18 are used to control switching respectively, and each set of heat exchangers performs heating, ice melting and deicing alternately. When the evaporator group 17 is running in the heating mode, the heating cycle main circuit 1 is conducted, the three-way valve 18 leads to the air inlet of the compressor 11, the ice-making check valve 16 is automatically opened, and the ice-melting check valve 24 The heating cycle main circuit 1 includes the evaporator group 17, the three-way valve 18, the compressor 11, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com