Processing and manufacturing method for high precision sand casting mold

A technology of sand casting and manufacturing methods, which is applied in the field of processing and manufacturing high-precision sand casting moulds, which can solve the problems of small feed amount, long processing time, and long tool path, so as to reduce manufacturing costs, save processing time, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: RuT300 cast iron has good plasticity and toughness, high thermal conductivity, small thermal stress concentration, good resistance to oxidation and growth at high temperatures, and is applied to parts and tools that withstand impact loads and thermal fatigue. Use RuT300 cast iron as the object to process a sand casting mold with a set of 2 pieces. The outer mold has a round corner area of R2.1mm, and it is processed with a general-purpose machining center.

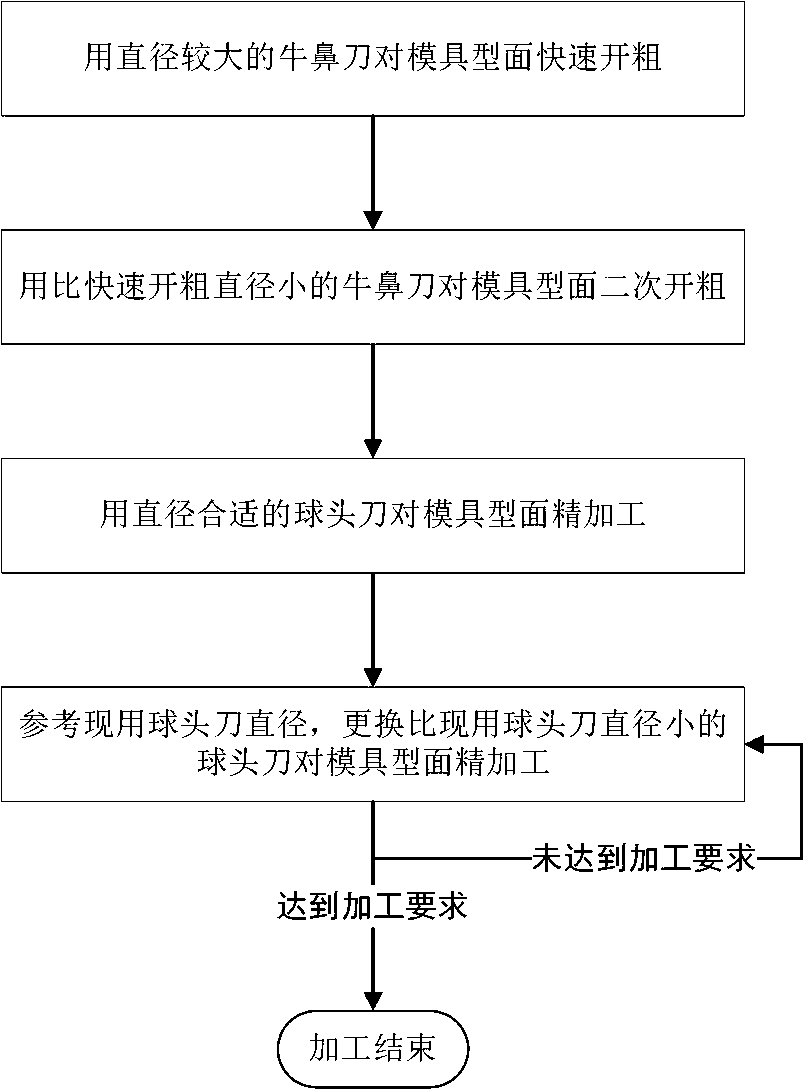

[0026] Processing steps such as figure 1 As shown, the specific steps are as follows:

[0027] Step (1): After fixing a piece of RuT300 cast iron blank used for processing the outer mold on the machine table, use a φ35 bull nose knife to quickly roughen the outer mold surface.

[0028] Step (2) Change the tool with a φ16 bullnose knife for secondary roughening of the outer model surface.

[0029] Step (3): Change the tool to a φ10 ball-end cutter for finishing on the outer model surface.

[0030] Ste...

Embodiment 2

[0034] Embodiment 2: use RuT300 cast iron as the object to process a sand casting mold core box 2 sets of 2 pieces, the core box has a rounded corner area of R2.1mm, and process it with a general-purpose machining center machine tool.

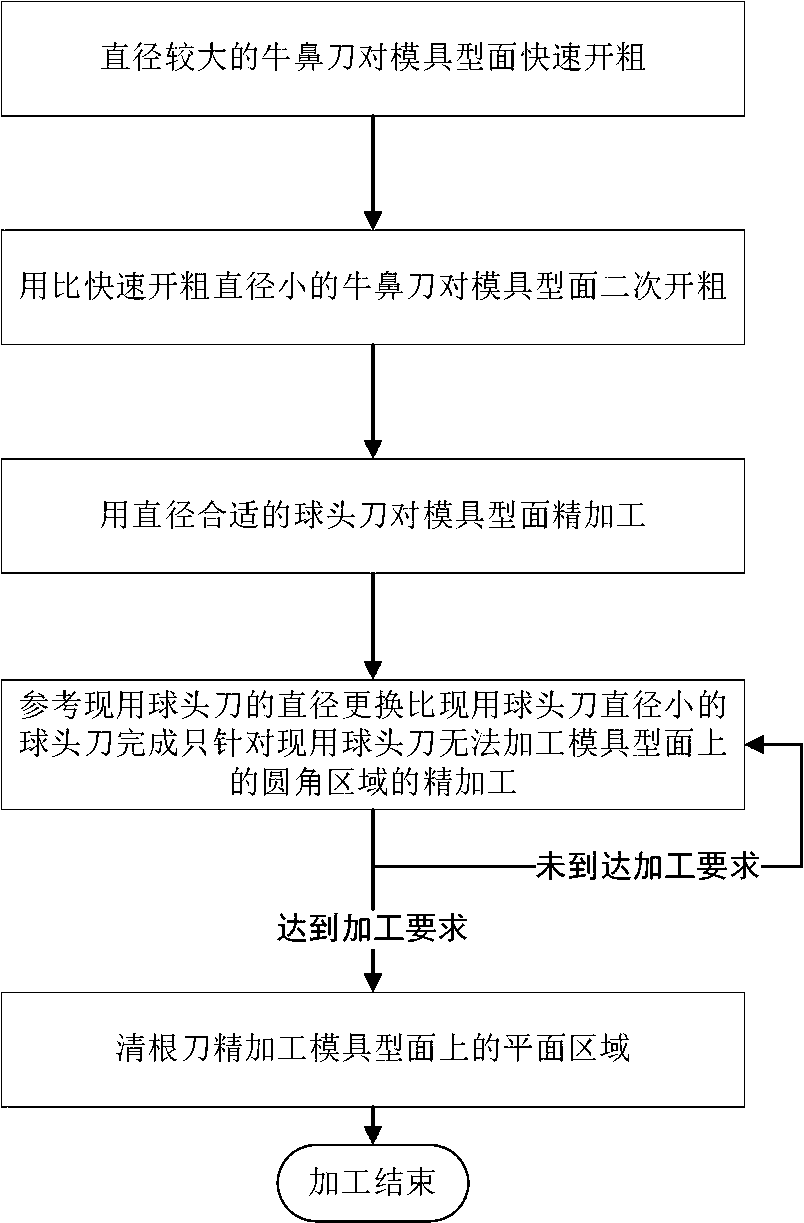

[0035] Specific steps are as follows:

[0036] Step (1): After fixing a piece of RuT300 cast iron blank used for processing the core box on the machine table, first use a φ25 bullnose knife core box profile to quickly rough it.

[0037] Step (2) Then change the tool and roughen the profile of the φ16 bullnose core box for the second time.

[0038] Step (3): Change the tool with a φ10 ball-end cutter to finish the core box profile.

[0039] Step (4): Only for the fillet area of the core box surface that cannot be processed by the φ10 ball nose knife, replace the φ8 ball nose knife for finishing; according to the size of the fillet design of the core box surface, the φ8 ball nose For the rounded area of the core box surface that cannot be...

Embodiment 3

[0043] Embodiment 3: use RuT300 cast iron as the object to process a sand casting mold core box 1 set, 1 piece, the core box has a rounded corner area of R3.2mm, and process it with a general-purpose machining center machine tool.

[0044] Specific steps are as follows:

[0045] Step (1): After fixing a piece of RuT300 cast iron blank used for processing the core box on the machine table, first use a φ35 bullnose knife core box profile to quickly rough it.

[0046] Step (2) Then change the tool and roughen the profile of the φ16 bullnose core box for the second time.

[0047]Step (3): Change the tool with a φ10 ball-end cutter to finish the core box profile.

[0048] Step (4): Only for the fillet area of the core box surface that cannot be processed by the φ10 ball-end knife, replace the φ8 ball-end knife for finishing; the size of the core according to the fillet design of the core box surface is R3.2mm For the fillet area of the box surface, continue to replace the φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com