Preparation method of water-dispersible aramid nanometer fiber/nanometer cellulose composite system and ultraviolet shielding type transparent thin film

A nanocellulose and nanofiber technology, which is applied in the field of composite materials, can solve the problems of narrow ultraviolet absorption band, low transparency, and difficult dispersion, etc., and achieves the effects of good ultraviolet shielding effect, simple preparation process, and breakthrough in poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

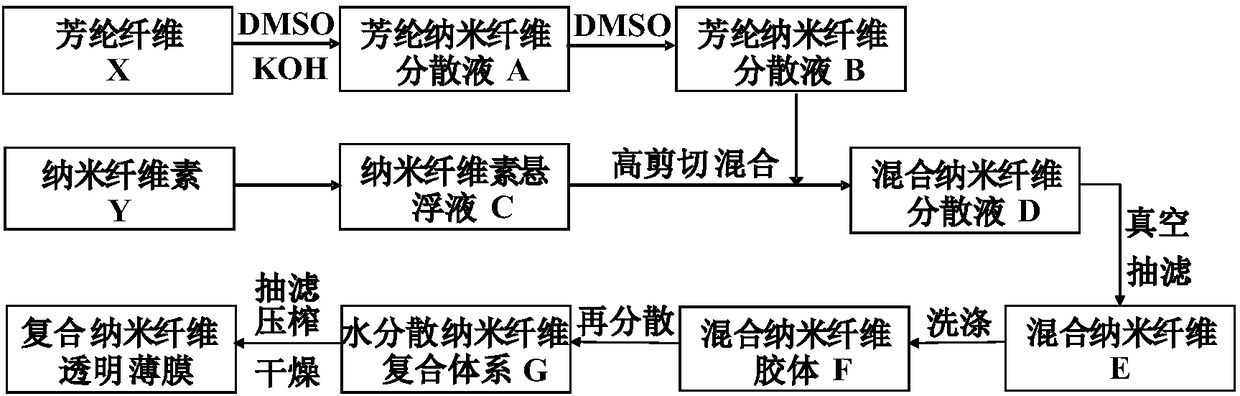

[0037] A method for preparing a water-dispersed aramid fiber nanofiber / nanocellulose composite system, comprising the following steps:

[0038] (1) Place para-aramid fiber X, potassium hydroxide, and dimethyl sulfoxide in a container, stir and disperse, and obtain aramid nanofiber dispersion A dispersed in the KOH / DMSO system;

[0039] Among them, the ratio of para-aramid fiber X, KOH and DMSO is 1g: 1.5g: 500mL; the stirring refers to stirring at a temperature of 30-60°C for 5-8 days under sealed conditions; the para-aramid Aramid fiber X is one of para-aramid yarn fibers, para-aramid chopped fibers, para-aramid pulp fibers and para-aramid fibrids;

[0040] (2) Dilute the aramid nanofiber dispersed in the KOH / DMSO system obtained in step (1) to obtain a uniformly dispersed aramid nanofiber dispersion B;

[0041] Wherein, the diluent is DMSO, and the volume concentration of the aramid nanofiber dispersion after dilution is 0.1 mg / mL;

[0042] (3) adding nanocellulose Y to de...

Embodiment 1

[0065] (1) Put 1g of para-aramid yarn fiber, 1.5g of potassium hydroxide and 500ml of dimethyl sulfoxide in a container, and stir at 30°C for 8 days under sealed conditions to obtain a mixture dispersed in KOH / DMSO Aramid nanofiber dispersion A under the system;

[0066] (2) Dilute the aramid nanofiber dispersed in the KOH / DMSO system obtained in step (1) with DMSO to obtain an aramid nanofiber dispersion B with an average volume concentration of 0.1 mg / mL;

[0067] (3) adding deionized water to the nanocellulose obtained by chemical acid hydrolysis and stirring for 12 hours at a stirring speed of 1000 rpm to obtain a uniformly dispersed nanocellulose suspension C with a mass concentration of 1%;

[0068] (4) With the nanocellulose suspension C obtained in step (3), under the effect of 600rpm, the aramid nanofiber dispersion obtained in the high-pressure injection step (2), the aramid nanofiber and The mass ratio of nanocellulose is 1:100, the jet pressure is 5MPa, and the je...

Embodiment 2

[0078] (1) Put 1.0g of para-aramid chopped fiber, 1.5g of potassium hydroxide and 500ml of dimethyl sulfoxide in a container, and stir at 40°C for 7 days under sealed conditions to obtain a mixture dispersed in KOH / Aramid nanofiber dispersion A under DMSO system;

[0079] (2) Dilute the aramid nanofiber dispersed in the KOH / DMSO system obtained in step (1) with DMSO to obtain an aramid nanofiber dispersion B with an average volume concentration of 0.1 mg / mL;

[0080](3) adding deionized water to the nanocellulose obtained by chemical pretreatment in conjunction with mechanical treatment and stirring for 12 hours at a stirring speed of 1000 rpm to obtain a uniformly dispersed nanocellulose suspension C with a mass concentration of 1%;

[0081] (4) With the nanocellulose suspension C obtained in step (3), under the effect of 1000rpm, the aramid nanofiber dispersion obtained in the high-pressure injection step (2), the aramid nanofiber and The mass ratio of nanocellulose is 3:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com