Preparation method of composite spinel/titanium dioxide green ceramic pigment

A spinel-type, titanium dioxide technology, applied in the field of ceramic pigments, can solve the problems of toxicity, large particle size, glaze pinholes, etc., and achieve the effect of high near-infrared reflectivity, high chemical stability, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

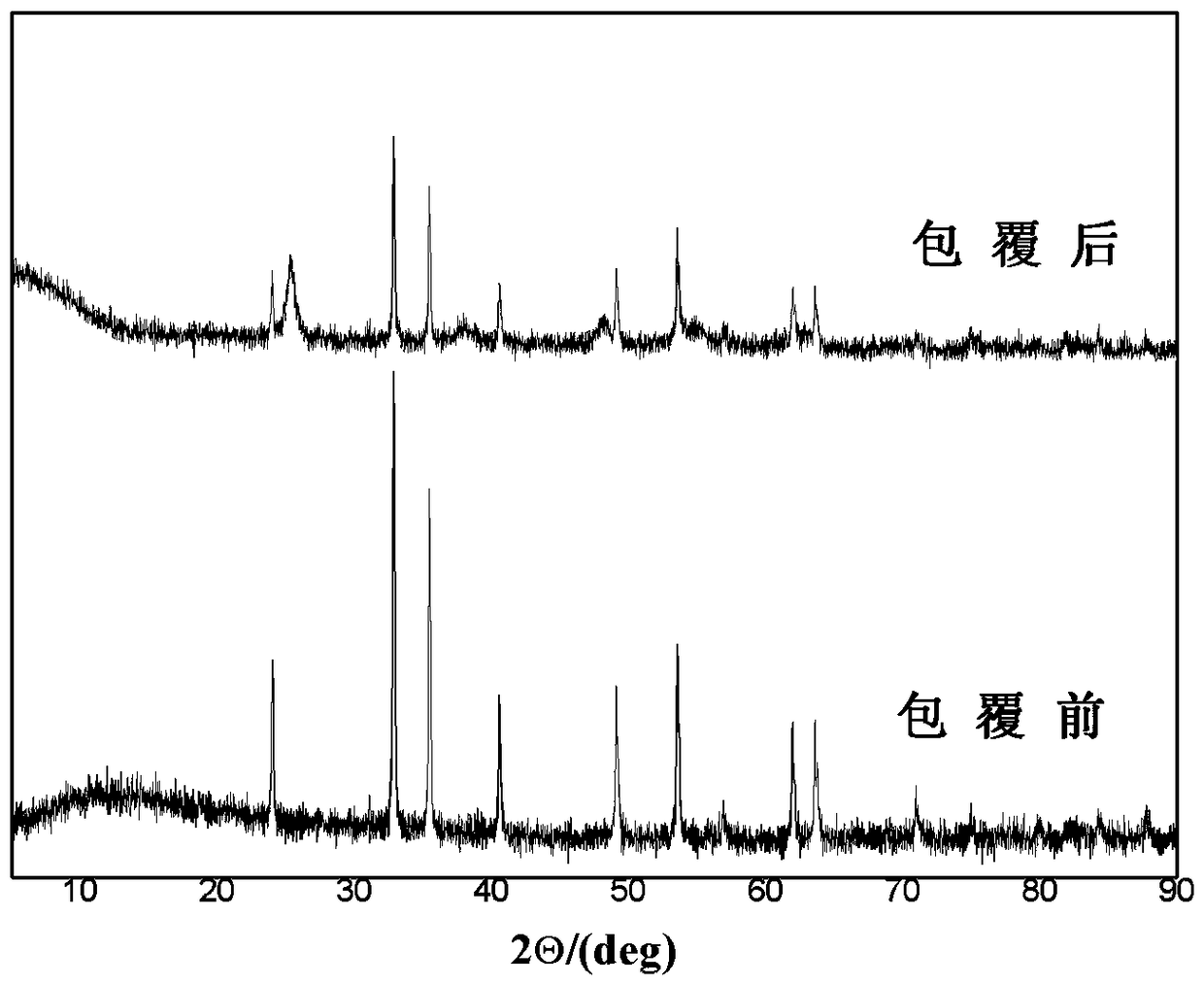

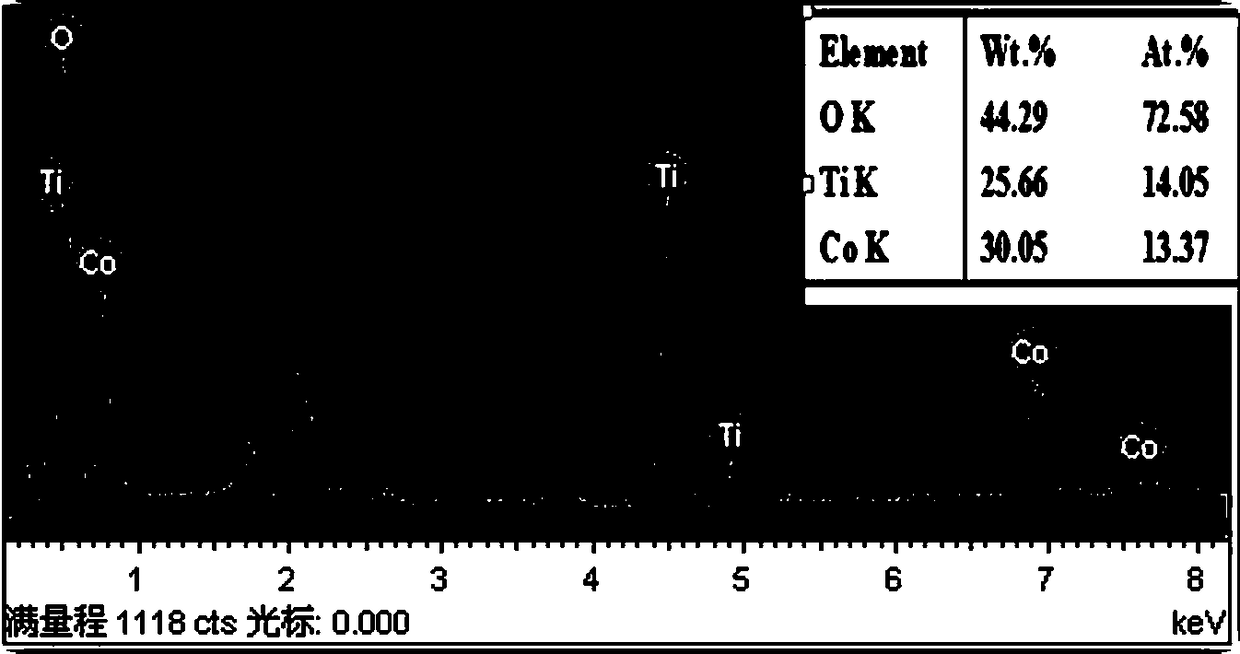

preparation example 1

[0030] Dissolve 2.9g of cobalt nitrate and 1.7g of butyl titanate in distilled water at room temperature, add 2.36g of succinic acid as a stabilizer, add ammonia dropwise to adjust the pH to 5.0, and add 0.38g of crosslinking agent ( 1,2-Propanediol) was added to the mixed solution, stirred for 4h, and the gelatinous solution was evaporated on a magnetic stirrer at 80°C. Then calcined at 350°C for 2h and at 700°C for 4h to obtain TiCo after grinding 2 O 4 Ceramic pigments.

preparation example 2

[0032] Dissolve 2.9g of cobalt nitrate and 1.7g of butyl titanate in distilled water at room temperature, add 2.36g of succinic acid as a stabilizer, add ammonia dropwise to adjust the pH to 6.0, and add 0.38g of crosslinking agent ( 1,2-Propanediol) was added to the mixed solution, stirred for 4h, and the gelatinous solution was evaporated on a magnetic stirrer at 80°C. Then calcined at 350°C for 2h and at 700°C for 4h to obtain TiCo after grinding 2 O 4 Ceramic pigments.

preparation example 3

[0034] Dissolve 2.9 g of cobalt nitrate and 1.7 g of butyl titanate in distilled water at room temperature, add 2.36 g of succinic acid as a stabilizer, add ammonia water dropwise to adjust the pH to 7.0, and add 0.38 g of crosslinking agent ( 1,2-Propanediol) was added to the mixed solution, stirred for 4h, and the gelatinous solution was evaporated on a magnetic stirrer at 80°C. Then calcined at 350°C for 2h and at 700°C for 4h to obtain TiCo after grinding 2 O 4 Ceramic pigments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com