Heavy metal soil repairing agent, and preparation method and use method thereof

A soil remediation agent and heavy metal technology, applied in the field of soil remediation, can solve the problems of soil secondary pollution, etc., and achieve the effect of controlling soil pollution, restoring arableness, and shortening the remediation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

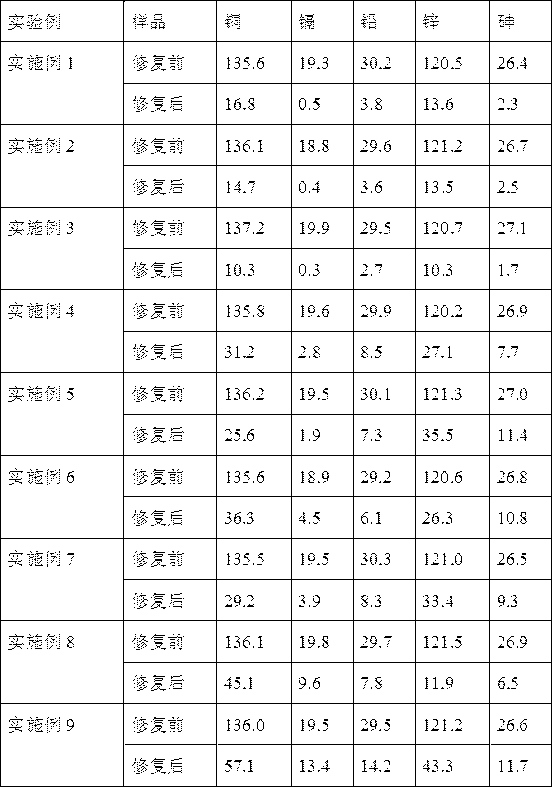

Examples

Embodiment 1

[0023] Get the raw materials for preparing the heavy metal soil remediation agent in the following parts by weight: 10 parts of polyacrylamide, 15 parts of zeolite, 10 parts of distilled water, 10 parts of cellulose xanthate calcium salt, 5 parts of modified apatite, 10 parts of molasses, 5 parts of biochar, 3 parts of phosphate compound, 3 parts of compound microbial agent.

[0024] Wherein, the preparation method of the cellulose xanthate calcium salt is as follows: add 400 mL of a 30% mass concentration sodium bicarbonate solution for every 10 g of water hyacinth straw powder, stir at a constant temperature of 38 ° C for half an hour, centrifuge, and retain the lower layer of solids. Wash with distilled water until the pH value is stable, centrifuge, discard the liquid phase; add 100mL of 10% mass concentration sodium hydroxide solution, stir for half an hour, then slowly add 0.15mL of CS 2 , stirred and reacted at 35°C for 1.5h, and carried out solid-liquid separation. The...

Embodiment 2

[0034] Get the raw materials for preparing the heavy metal soil remediation agent in the following parts by weight: 15 parts of polyacrylamide, 10 parts of zeolite, 15 parts of distilled water, 15 parts of cellulose xanthate calcium salt, 10 parts of modified apatite, 10 parts of molasses, 8 parts of biochar, 5 parts of phosphate compounds, and 1 part of compound microbial agent.

[0035]Wherein, the preparation method of the cellulose xanthate calcium salt is as follows: add 350mL of 35% mass concentration sodium bicarbonate solution for every 10g of water hyacinth stalk powder, stir at a constant temperature of 45°C for half an hour, centrifuge, and retain the lower layer solid, Wash with distilled water until the pH value is stable, centrifuge, and discard the liquid phase; add 150 mL of 10% mass concentration sodium hydroxide solution, stir for half an hour, and then slowly add 0.15 mL of CS 2 , stirred and reacted at 40°C for 1 hour, and carried out solid-liquid separatio...

Embodiment 3

[0045] Get the raw materials for preparing the heavy metal soil remediation agent in the following parts by weight: 13 parts of polyacrylamide, 12 parts of zeolite, 15 parts of distilled water, 13 parts of cellulose xanthate calcium salt, 8 parts of modified apatite, 8 parts of molasses, 7 parts of biochar, 4 parts of phosphate compound, 2 parts of compound microbial agent.

[0046] Wherein, the preparation method of the cellulose xanthate calcium salt is as follows: add 380mL of 33% mass concentration sodium bicarbonate solution for every 10g of water hyacinth stalk powder, stir at a constant temperature of 40°C for half an hour, centrifuge, and retain the lower layer solid, Wash with distilled water until the pH value is stable, centrifuge, discard the liquid phase; add 125ml of 10% mass concentration sodium hydroxide solution, stir for half an hour, then slowly add 0.15mL of CS 2 , stirred and reacted at 38°C for 1.5h, and carried out solid-liquid separation, and adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com