Pressure maintaining-free PUR hot-melt adhesive and preparation method thereof

A technology of hot melt adhesives and functional additives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor initial adhesion, low efficiency, and long holding time, and achieve strength No attenuation, wide application range, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the pressure-holding-free PUR hot-melt adhesive that the present invention proposes, the steps are as follows:

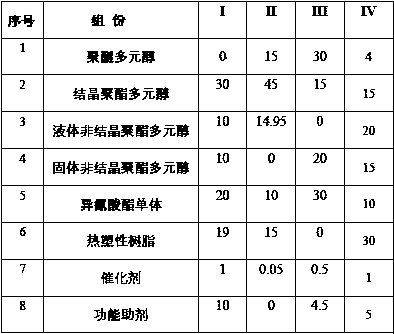

[0041] Step 1: Weigh the Portions

[0042] Each component is weighed according to the proportion of the pressure-free PUR hot melt adhesive, wherein, as required, the components of the functional additive are selected, and the specific gravity of each component is determined.

[0043] Step 2: Raw material dehydration

[0044] Put the polyether polyol and thermoplastic resin into the reaction kettle, stir and dissolve in vacuum at 120~130°C for 2 hours; then add crystalline polyester polyol, liquid non-crystalline polyester polyol, solid non-crystalline polyester polyol 1. Put it into the reaction kettle, under the nitrogen condition of 120-130 ℃, vacuum stir to remove water for more than 1 hour, until the water content does not exceed 500ppm, and obtain the primary mixture. When the input components contain powder, first turn on th...

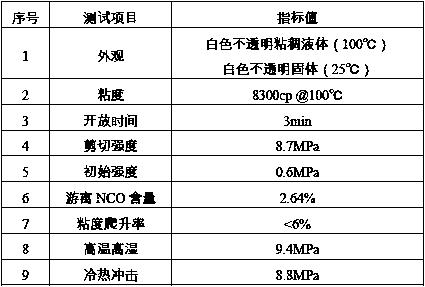

Embodiment 1

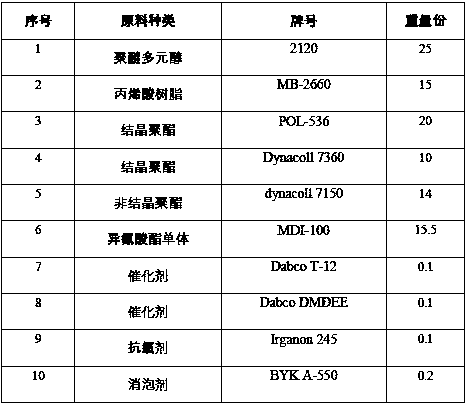

[0070] The present embodiment is formulated from the following raw materials in weight percentage:

[0071]

[0072] According to the above weight percentage formula, the process steps of preparing pressure-free hot melt adhesive are as follows:

[0073] (1) Dehydration of raw materials: Put 25 parts of polyether polyol 2120 and 15 parts of acrylic resin BR106 into a dual planetary mixer reactor, stir and dissolve in vacuum at 120-130°C for 2 hours, and under nitrogen, mix 20 parts of crystalline polyester polyol Alcohol POL-536, 10 parts of crystalline polyester polyol dynacoll 7360, 14 parts of non-crystalline polyester polyol dynacoll 7150, antioxidant Irganon245, defoamer BYK A-550 were put into the reactor, the nitrogen gas was turned off, and the reactor was sealed. After the material is basically melted, turn on stirring and dispersing. Under the condition of 120-130°C, remove water under vacuum for 2 hours, and test the moisture content of the material. If the moist...

Embodiment 2

[0080] The present embodiment is formulated from the following raw materials in weight percentage:

[0081]

[0082] According to the above weight percentage formula, the process steps of preparing pressure-free hot melt adhesive are as follows:

[0083] (1) Dehydration of raw materials: Put 20 parts of polyether polyol WD2110 and 12 parts of acrylic resin BR113 into a dual planetary mixer reactor, stir and dissolve in vacuum at 120-130°C for 2 hours, and under nitrogen, mix 32 parts of crystalline polyester polyol Alcohol POL-538, 10 parts of non-crystalline polyester polyol dynacoll 7210, 10 parts of non-crystalline polyester polyol dynacoll 7150, 0.15 parts of defoamer BYKA-550, 0.1 part of dehydrating agent Additive TI were put into the reactor, and the nitrogen gas was turned off. Seal the reaction kettle. After the material is basically melted, start the stirring and start the dispersion. Under the condition of 120-130 ℃, remove the water in vacuum for 2 hours, and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com