Method for preparing rare earth fluorescent silicon dioxide nanoparticles by microwave heating technology

A technology of silica and nanoparticles, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of preparation methods of rare earth fluorescent silica nanoparticles, particle surface The chemical modification process takes a long time and the wide application of unfavorable markers, etc., to achieve good selective heating and high efficiency, uniform size, and shorten the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

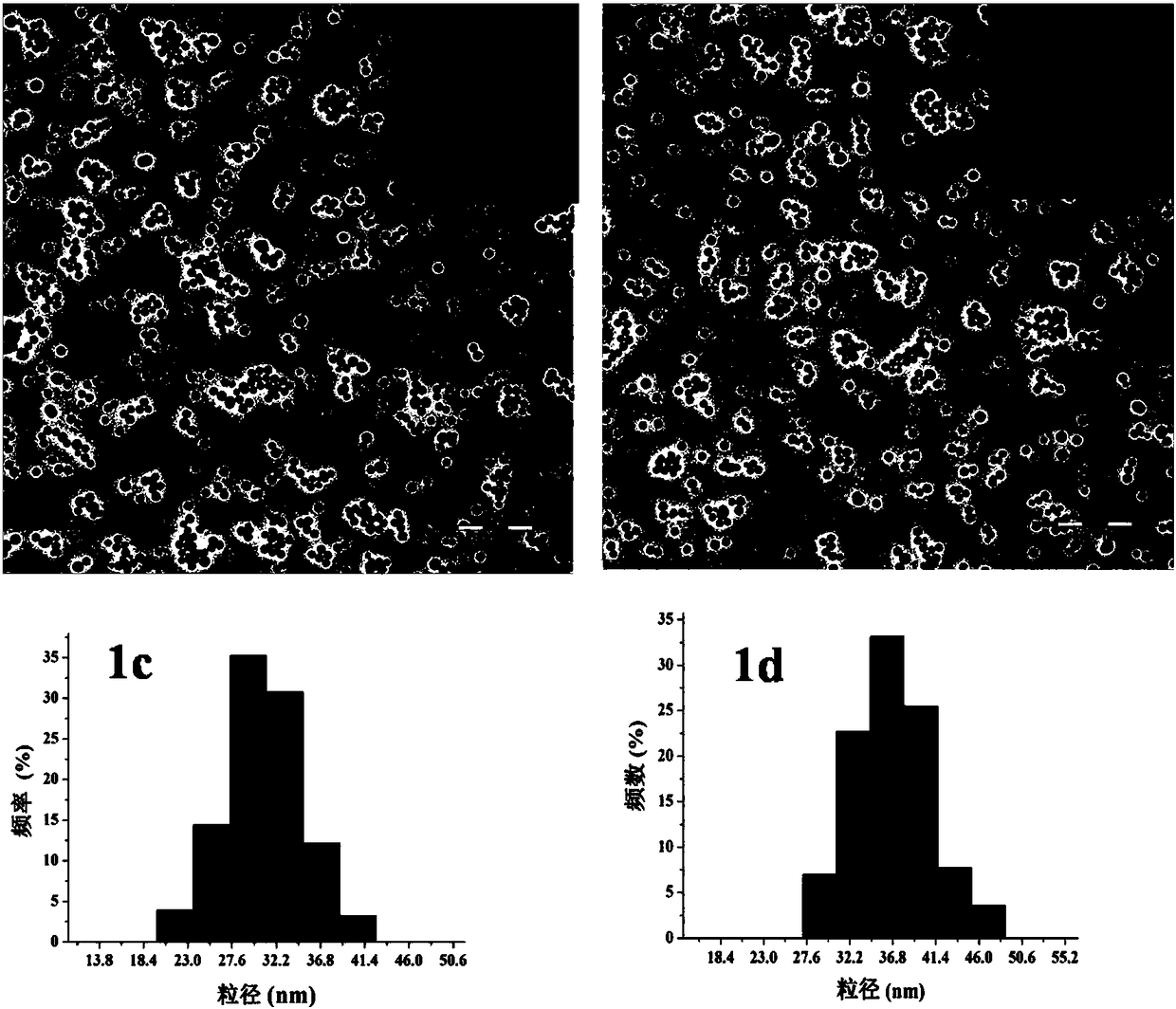

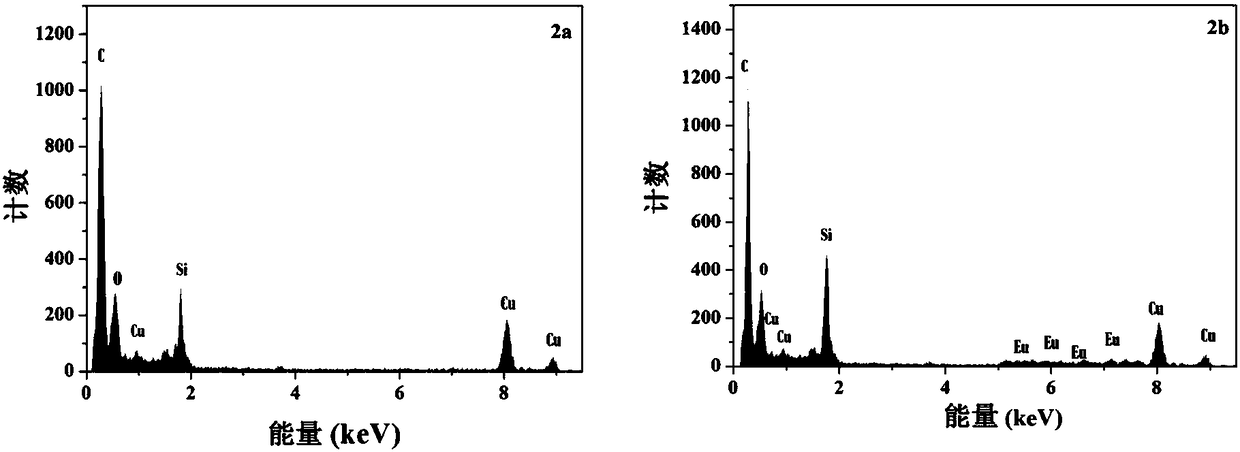

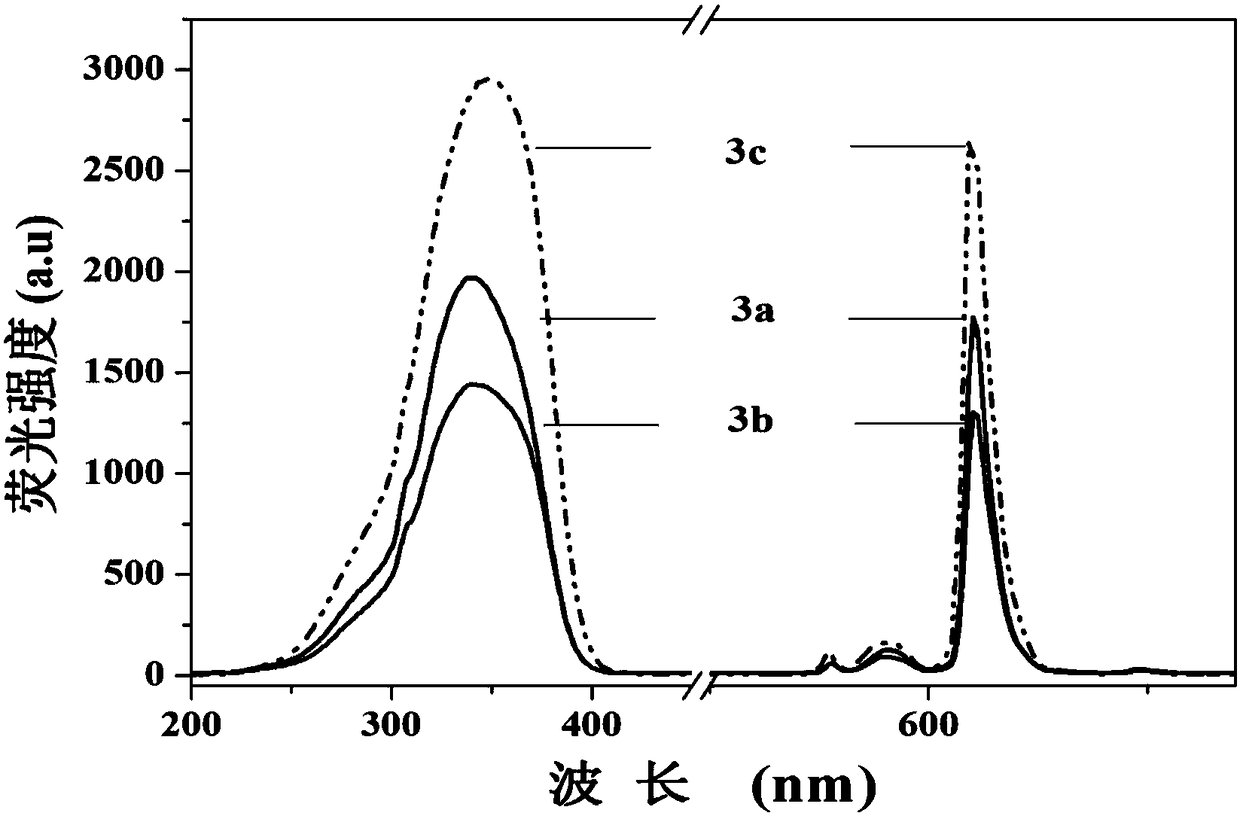

[0039] Example 1: Preparation of Eu by Microwave Heating Technology 3+ -BHHCT@SiO 2 Fluorescent rare earth silica nanoparticles, research experiments on the effect of different microwave reaction times on fluorescence properties

[0040] (1) Preparation of silica nanoparticles: Take 6mL of cyclohexane, 2.13mL of Tx-100, 1.87mL of n-octanol and 0.6mL of ultrapure water into the Erlenmeyer flask, stir magnetically, and after stirring evenly, add 100 μL TEOS and 60 μL ammonia water were stirred at room temperature for 24 hours to obtain SiO 2 Nano microemulsion. .

[0041] (2) Surface amination of silica nanoparticles: Add 3 μL of 3-aminopropyltrimethoxysilane (APTMs) to the SiO obtained in (1). 2 In the nano-microemulsion, microwave heating, microwave power 700W, temperature 70°C, reaction time 10min, 20min, 30min, 40min.

[0042] (3) BHHCT-Eu 3+ Synthesis of fluorescent rare earth complexes: 5 mg of 4,4'-bis(1",1",1",2",2",3",3"-heptafluoro-4",6"-hexanedione -6"-yl)-chlo...

Embodiment 2

[0045] Example 2: Preparation of Eu by Microwave Heating Technology 3+ -BHHCT@SiO 2 Fluorescent rare earth silica nanoparticles, research experiment on the effect of different microwave reaction temperatures on fluorescent properties

[0046] (1) Preparation of silica nanoparticles: same as in Example 1.

[0047] (2) Surface amination of silica nanoparticles: Take 3 μL APTMs and add them to the SiO obtained in (1) 2 In the nano microemulsion, microwave heating, microwave power 700W, investigation temperature 70°C and 60°C, reaction time 20min.

[0048] (3) BHHCT-Eu 3+ Synthesis of Fluorescent Rare Earth Complex: Same as Example 1.

[0049] (4) BHHCT-Eu 3+ Preparation of modified silica fluorescent nanoparticles: add the fluorescent complex obtained in step (3) to the microemulsion system in (2), heat with microwave, microwave power 700W, temperature 59°C and 50°C, reaction time 20min. Add 5mL of acetone, mix well, centrifuge, then wash the particles with ethanol / water (v...

Embodiment 3

[0051] Example 3: Preparation of Eu by Microwave Heating Technology 3+ -BHHCT@SiO 2 Fluorescent rare earth silica nanoparticles, research experiments on the effect of different microwave power on fluorescent properties

[0052] (1) Preparation of silica nanoparticles: same as in Example 1.

[0053] (2) Surface amination of silica nanoparticles: Take 3 μL APTMs and add them to the SiO obtained in (1) 2 In the nano microemulsion, microwave heating, microwave power investigation 600W, 700W, 800W, 900W and 1000W, investigation temperature 70 ℃, reaction time 20min.

[0054] (3) BHHCT-Eu 3+ Synthesis of Fluorescent Rare Earth Complex: Same as Example 1.

[0055] (4) BHHCT-Eu 3+ Preparation of modified silica fluorescent nanoparticles: Add the fluorescent complex obtained in step (3) to the microemulsion system in (2), microwave heating, microwave power 600W, 700W, 800W, 900W and 1000W, temperature 59 ℃, reaction time 20min. Add 5mL of acetone, mix well, centrifuge, then wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com