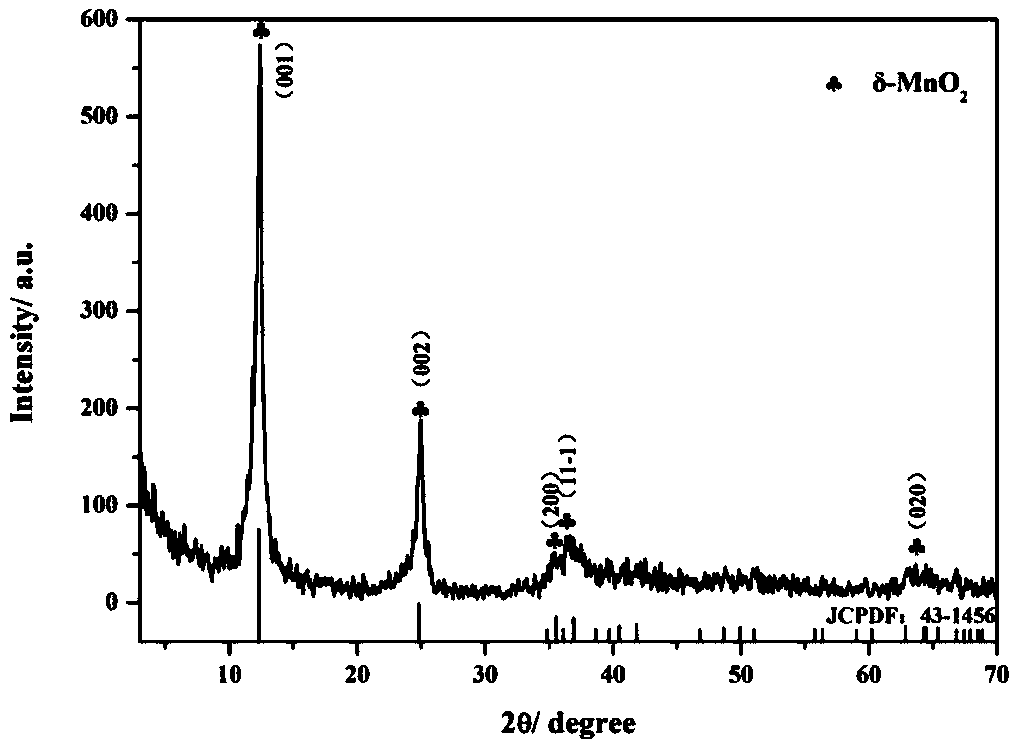

Method for preparing delta-MnO2 nanosheet

A nanosheet, H2O2 technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of low electronic conductivity, volume change, loss of active materials, etc., and achieve the effect of simple preparation process, good dispersion and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] MnO 2 The preparation method of nano sheet, comprises the following steps:

[0022] Step 1: Dissolve 8.04g NaOH in 300mL deionized water, stir the solution for a period of time until NaOH is completely dissolved;

[0023] Step 2: Dilute 35 mL of 30% H 2 o 2 Quickly add to the solution obtained in step 1 and mix well;

[0024] Step 3: 10mL mass fraction is 50% Mn(NO 3 ) 2 Dissolve in 133mL of deionized water;

[0025] Step 4: The mixed solution obtained in step 2 is quickly added to the prepared Mn(NO 3 ) 2 In the solution, stir quickly until the mixture is uniform;

[0026] Step 5: standing the mixed solution obtained in step 4 to obtain a sediment, washing the sediment to neutrality and then drying to obtain an intermediate product;

[0027] Step 6: Add 80% of the intermediate product obtained in step 5 into a NaOH solution with a concentration of 2 mol / L, stir evenly, and then transfer to a high-pressure reactor, and the volume of the solution is controlled a...

Embodiment 2

[0030] MnO 2 The preparation method of nano sheet, comprises the following steps:

[0031] Step 1: Dissolve 12.3g NaOH in 458mL deionized water, stir the solution for a period of time until NaOH is completely dissolved;

[0032] Step 2: Dilute 47 mL of 30% H 2 o 2 Quickly add to the solution obtained in step 1 and mix well;

[0033] Step 3: 18mL mass fraction is 50% Mn(NO 3 ) 2 Dissolve in 240mL of deionized water;

[0034] Step 4: The mixed solution obtained in step 2 is quickly added to the prepared Mn(NO 3 ) 2 In the solution, stir rapidly for 30 minutes until the mixture is uniform;

[0035] Step 5: The mixed solution obtained in Step 4 is left standing, washed to neutral and then dried to obtain an intermediate product;

[0036] Step 6: Add 80% of the intermediate product obtained in step 5 into 80 mL of NaOH solution with a concentration of 2.5 mol / L, stir evenly and transfer to a high-pressure reactor, and the volume of the solution is controlled at 75% of the ...

Embodiment 3

[0039] MnO 2 The preparation method of nano sheet, comprises the following steps:

[0040] Step 1: Dissolve 9.6g NaOH in 359mL deionized water, stir the solution for a period of time until NaOH is completely dissolved;

[0041] Step 2: Dilute 41 mL of 30% H 2 o 2 Quickly add to the solution obtained in step 1 and mix well;

[0042] Step 3: 14mL mass fraction is 50% Mn(NO 3 ) 2 Dissolve in 186mL of deionized water;

[0043] Step 4: The mixed solution obtained in step 2 is quickly added to the prepared Mn(NO 3 ) 2 In the solution, stir rapidly for 30 minutes until the mixture is uniform;

[0044] Step 5: The mixed solution obtained in Step 4 is left standing, washed to neutral and then dried to obtain an intermediate product;

[0045]Step 6: Add 80% of the intermediate product obtained in step 5 into 100 mL of NaOH solution with a concentration of 2 mol / L, stir evenly and transfer to a high-pressure reactor, and the volume of the solution is controlled at 80% of the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com