Method for producing dry-mixed mortar from metal tailing slag

A technology of dry-mixed mortar and metal tailings, which is applied in the field of dry-mixed mortar produced from metal tailings slag, can solve problems such as lack of research, achieve the effects of reducing production costs, solving high stockpiling costs, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

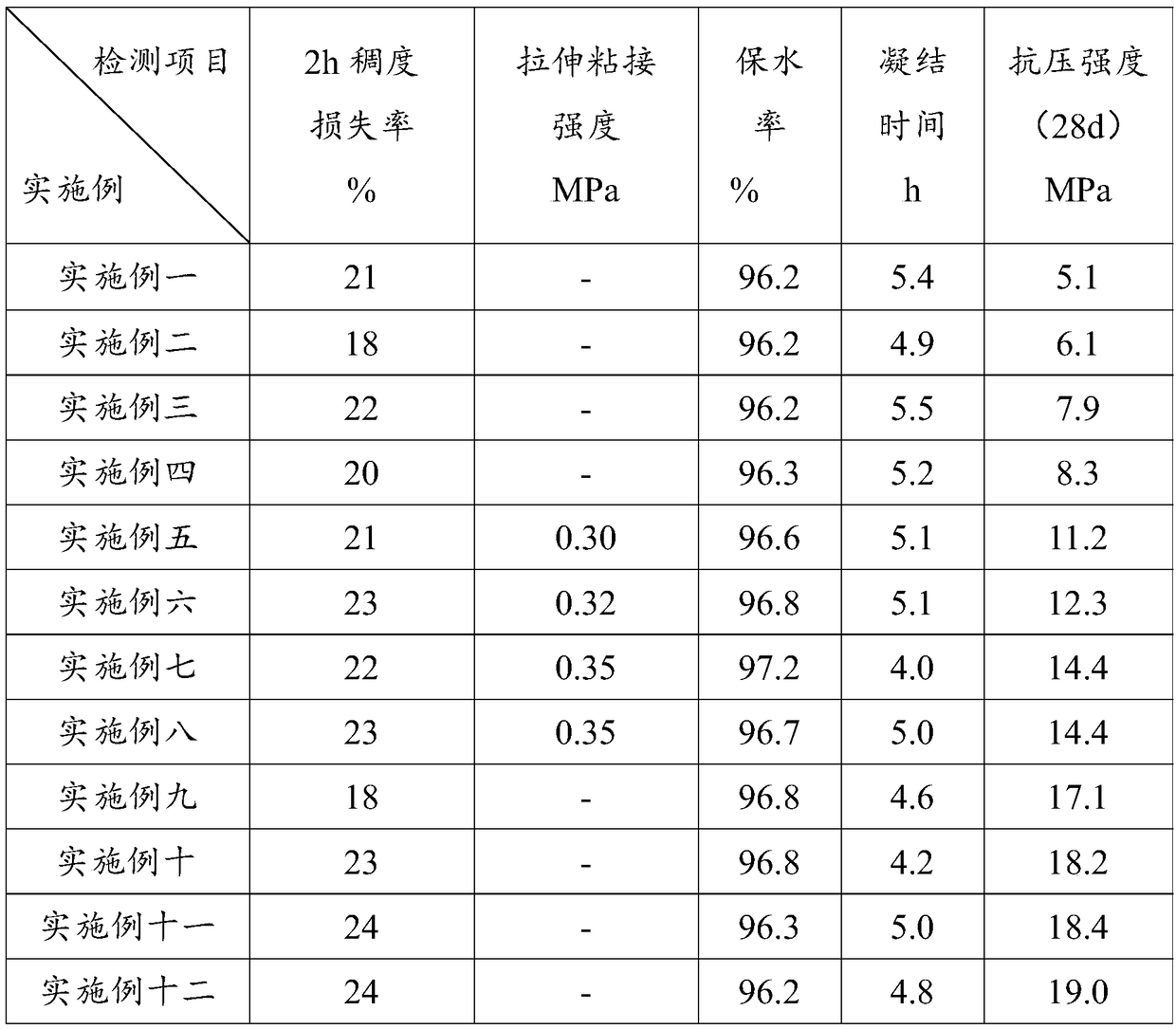

Examples

Embodiment 1

[0022] A method for producing dry-mixed mortar from metal tailings slag, comprising the following steps:

[0023] S1. Dry the metal tailings slag through a dryer, and then remove iron through a magnetic separator. The metal tailings slag is in accordance with the "Leach Toxicity Identification of Hazardous Waste Identification Standards" GB 5085.3-2007 and "Radionuclide Limits for Building Materials" The relevant regulations of GB6566-2010 test its internal exposure index, external exposure index, copper content, zinc content, cadmium content, lead content, total chromium content, hexavalent chromium content, beryllium content, barium content, nickel content, total silver content, The arsenic content, selenium content, and the test results all meet the standards; the metal tailings are iron tailings or copper tailings;

[0024] S2. Screen the metal tailings slag obtained in step S1 from large to small through vibrating particle size sieves of 4.75mm, 2.36mm, 0.63mm, and 0.16mm...

Embodiment 2

[0029] The method of utilizing metal tailings slag to produce dry-mixed mortar shown in this embodiment, its steps S1, S2 are the same as embodiment one, and the difference from embodiment one is:

[0030] S3. According to the percentage by weight, add 0.25% activator and 99.75% metal tailings ultra-fine sand to the mixer for stirring and homogenization, and then grind with an activated energy-saving mill to obtain a specific surface area of 500m 2 kg -1 tailings fine powder;

[0031] S4, the metal tailings fine sand obtained in step S2, the metal tailings medium sand and the metal tailings coarse sand are mixed together to obtain A sand, according to the weight ratio, 19.97% cement, 60% A sand, 20 % tailings fine powder and 0.03% water-retaining agent were put into a mixer for stirring and homogenizing to prepare dry-mixed mortar for masonry.

[0032] The cement is 42.5R general-purpose Portland cement, the activator is composed of glycerin, triisopropanolamine, molasses,...

Embodiment 3

[0034] The method of utilizing metal tailings slag to produce dry-mixed mortar shown in this embodiment, its steps S1, S2 are the same as embodiment one, and the difference from embodiment one is:

[0035] S3. According to the percentage by weight, add 0.20% activator and 99.80% metal tailings ultra-fine sand to the mixer for stirring and homogenization, and then grind with an activated energy-saving mill to obtain a specific surface area of 500m 2 kg -1 tailings fine powder;

[0036] S4, the metal tailings fine sand obtained in step S2, the metal tailings medium sand and the metal tailings coarse sand are mixed together to obtain A sand, and according to the weight ratio, 17% cement, 65% A sand, 17.97 % tailings fine powder and 0.03% water-retaining agent were put into a mixer for stirring and homogenizing to prepare dry-mixed mortar for masonry.

[0037] The cement is 42.5R general-purpose Portland cement, the activator is composed of glycerin, triisopropanolamine, molas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com