A kind of preparation method of microvascular self-healing coating

A microvascular and self-repairing technology, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of difficult transplantation, liquid paraffin is not difficult to clean, unfavorable for the promotion and application of microvascular self-repairing coating, etc., to achieve strong applicability, The effect of high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

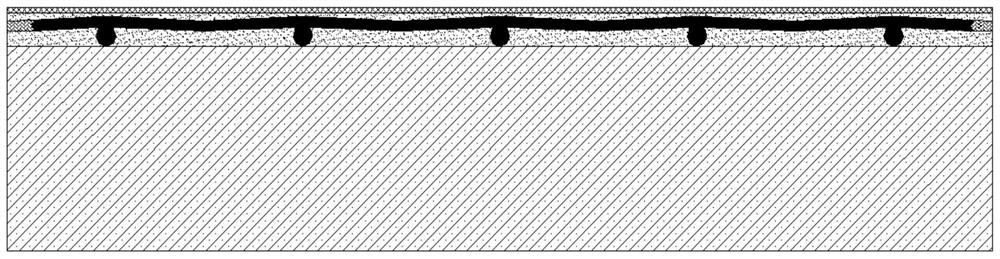

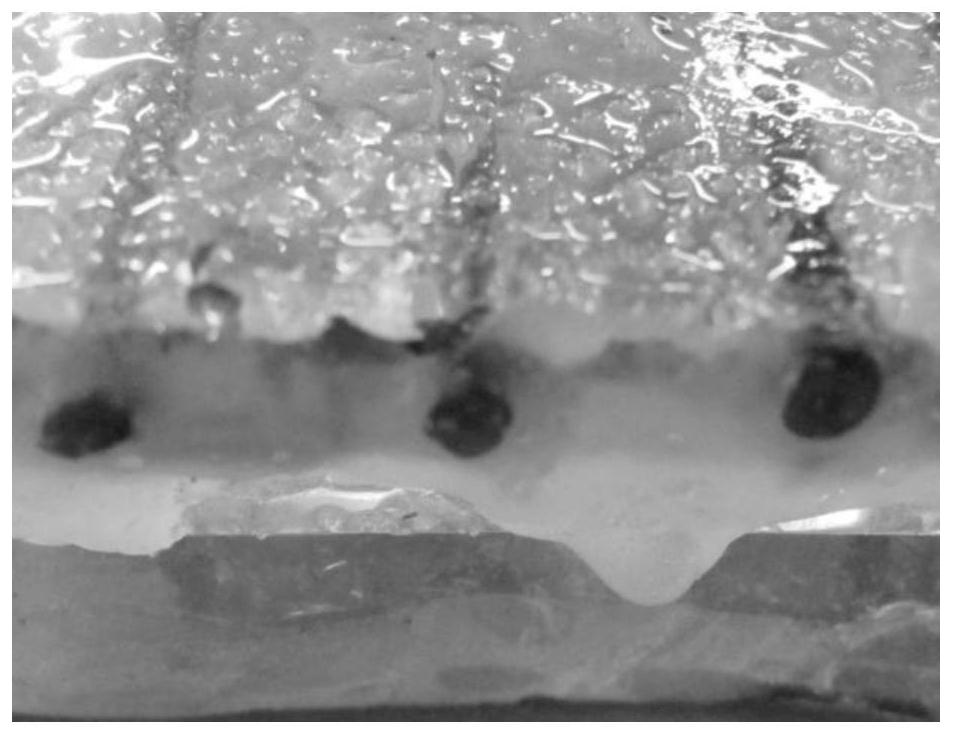

Image

Examples

Embodiment 1

[0055] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0056] Step 1, surface modification of filler: first weigh a certain amount of muscovite, ground calcium carbonate, quartz powder and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to 1.5% of the mass of the filler, dilute the silane coupling agent KH-560 with absolute ethanol to an 8% solution by mass, and spray it evenly into the In the corresponding filler, and then dried at 60°C for later use;

[0057] Step 2, the preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 80 parts of acetone solvent, add 9 parts of diethylenetriamine and 2 parts of benzyl alcohol after dissolving, and stir well Add 150 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 100 parts of modified muscovite and 200 parts of modified calcium carbonate in turn, and add 50 parts ...

Embodiment 2

[0062] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0063] Step 1, surface modification of filler: first weigh a certain quality of talcum powder, light calcium carbonate instead, quartz powder and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to the mass of 2% of the filler, dilute the silane coupling agent KH-560 with absolute ethanol into a 5% solution by mass, and spray it into the In the corresponding filler, and then dried at 60°C for later use;

[0064] Step 2, preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 70 parts of acetone solvent, add 9 parts of diethylenetriamine and 2 parts of benzyl alcohol after dissolving, and stir well Add 200 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 100 parts of modified muscovite and 300 parts of modified calcium carbonate in sequence, and add 10 pa...

Embodiment 3

[0069] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0070] Step 1, surface modification of fillers: first weigh a certain amount of bentonite, ground calcium carbonate, titanium dioxide and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to 1.5% of the mass of the filler, dilute the silane coupling agent KH-560 with absolute ethanol to a 5% solution by mass, and spray it into the In the corresponding filler, and then dried at 60°C for later use;

[0071] Step 2, preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 80 parts of acetone solvent, add 9 parts of diethylenetriamine and 3 parts of benzyl alcohol after dissolving, and stir well Add 200 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 90 parts of modified muscovite and 200 parts of modified calcium carbonate in turn, and add 30 parts of aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com