Tunnel kiln for treating organic refuse by utilizing afterheat

A technology for organic waste and waste heat treatment, applied in the field of tunnel kilns, which can solve problems such as environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

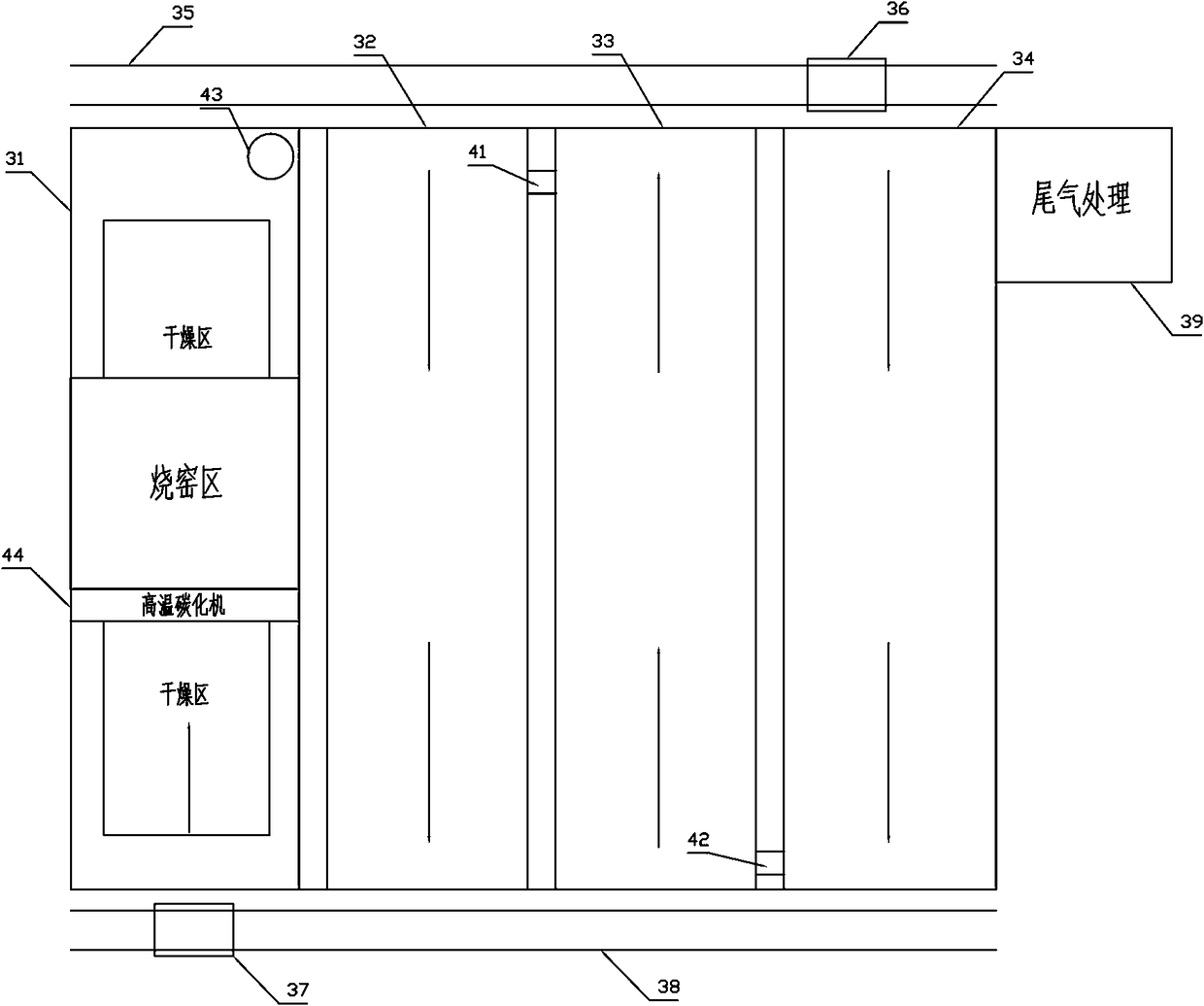

[0025] Such as figure 1 As shown, a tunnel kiln that utilizes waste heat to treat organic waste includes:

[0026] fan 43;

[0027] Dryer 7;

[0028] High temperature carbonization machine 44;

[0029] Exhaust gas treatment device 39;

[0030] A tunnel kiln body composed of one firing line 31 and three drying lines;

[0031] Transfer rails and transfer vehicles distributed on both sides of the main body of the tunnel kiln;

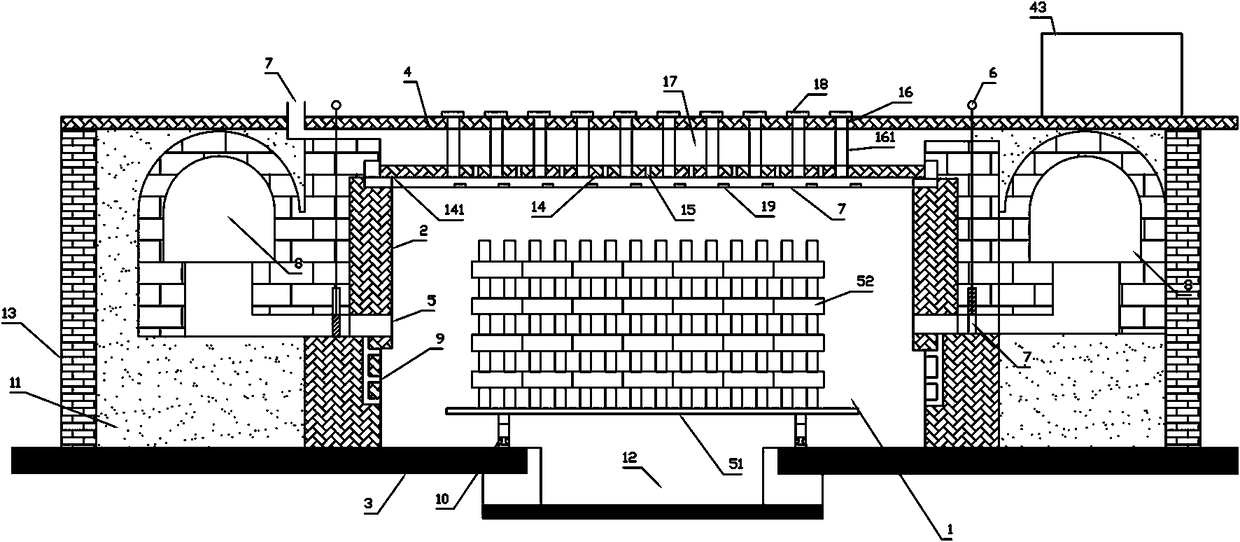

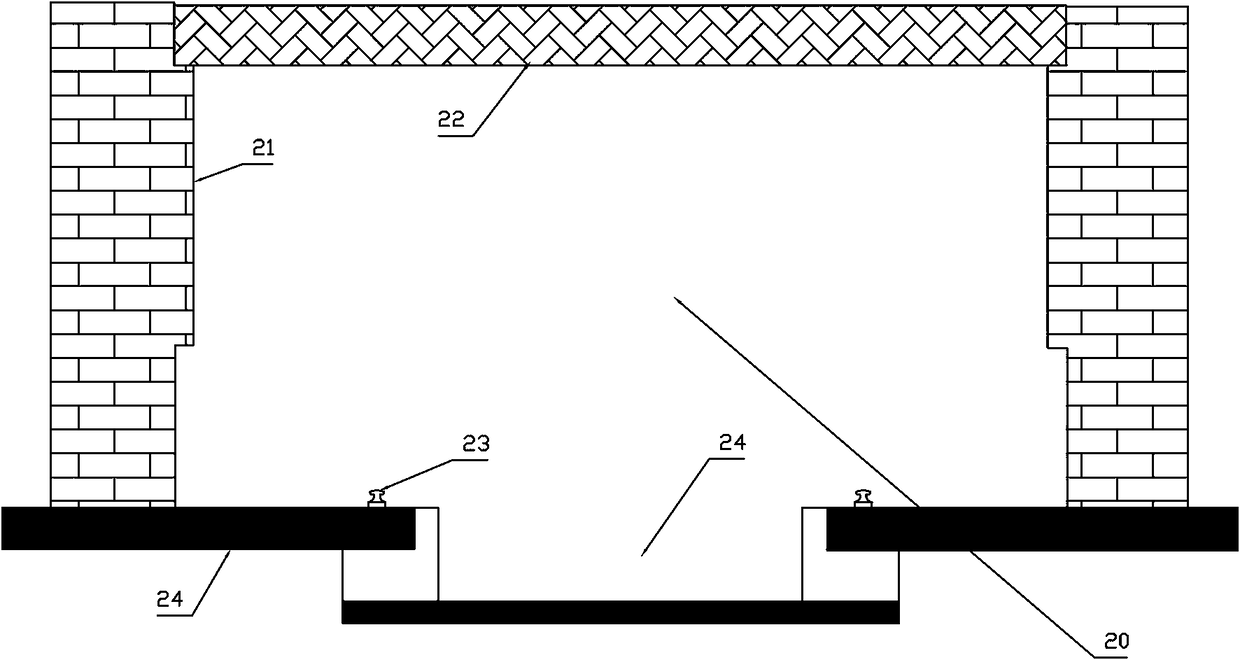

[0032] Wherein, described burning line 31 and drying line 32, drying line 33, drying line 34 are arranged side by side, as figure 2 As shown, the burning line 31 includes a tunnel 1 composed of side walls 2 on both sides, a top wall 14, and a base plate 3 at the bottom, air passages 8 arranged on both sides of the tunnel 1, tracks 10 arranged in the tunnel 1, and arranged on The wind trench under the track 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com