Visible-infrared broadband absorber and preparation method thereof

An absorber and broadband technology, applied in the fields of photothermal conversion and optical devices, can solve the problems of cumbersome preparation, difficulty in large-area production, complex structure, etc., and achieve the effects of simple process, shortened production cycle and high absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

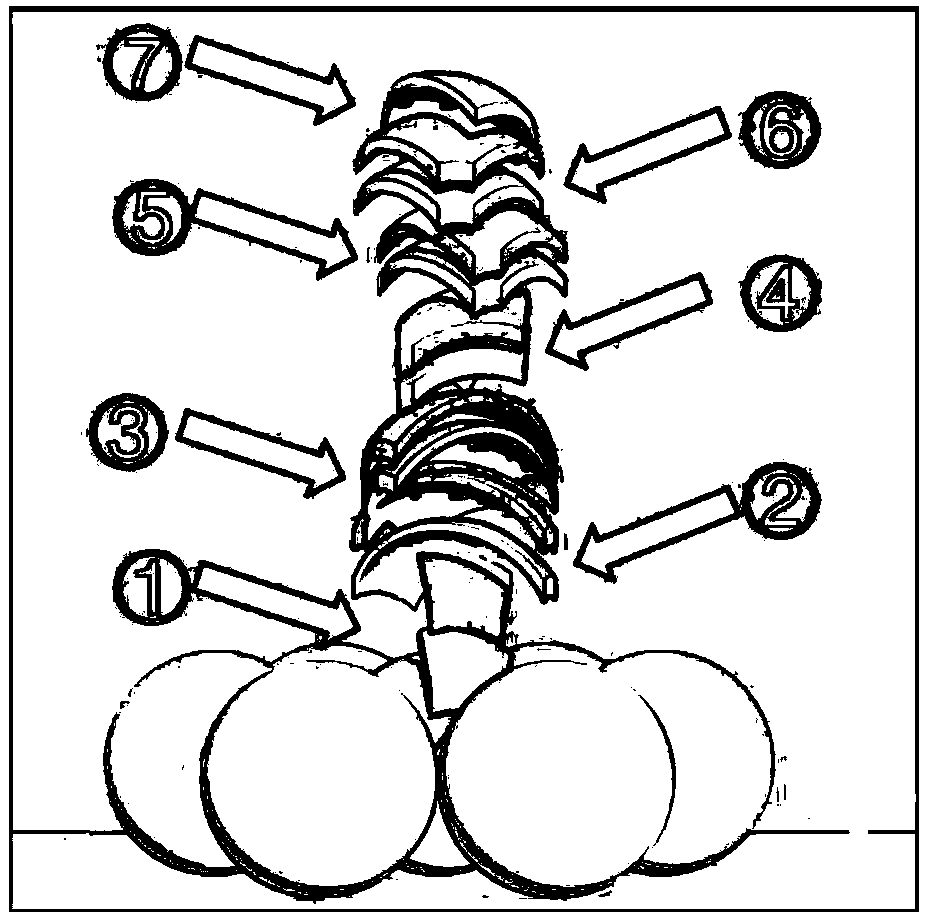

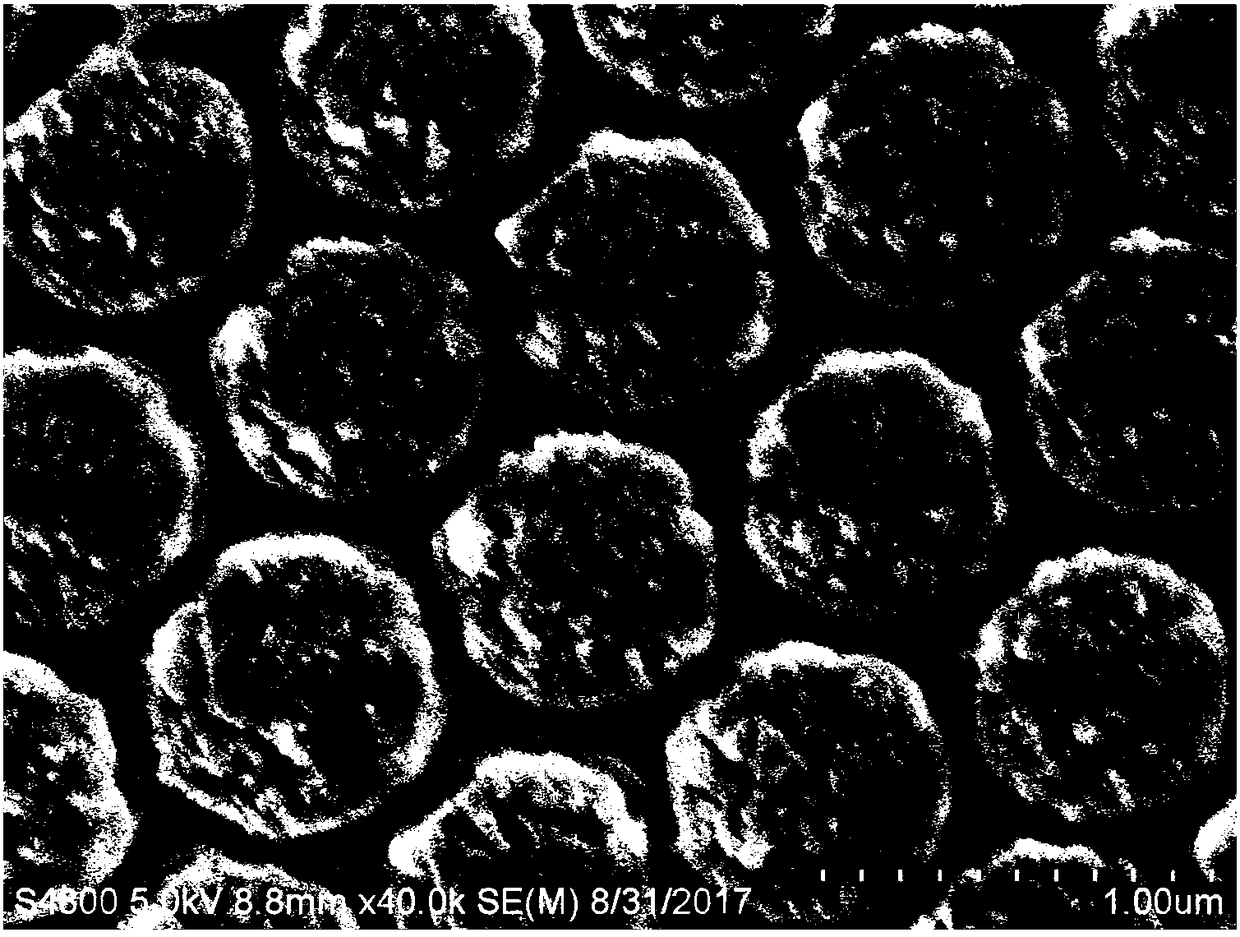

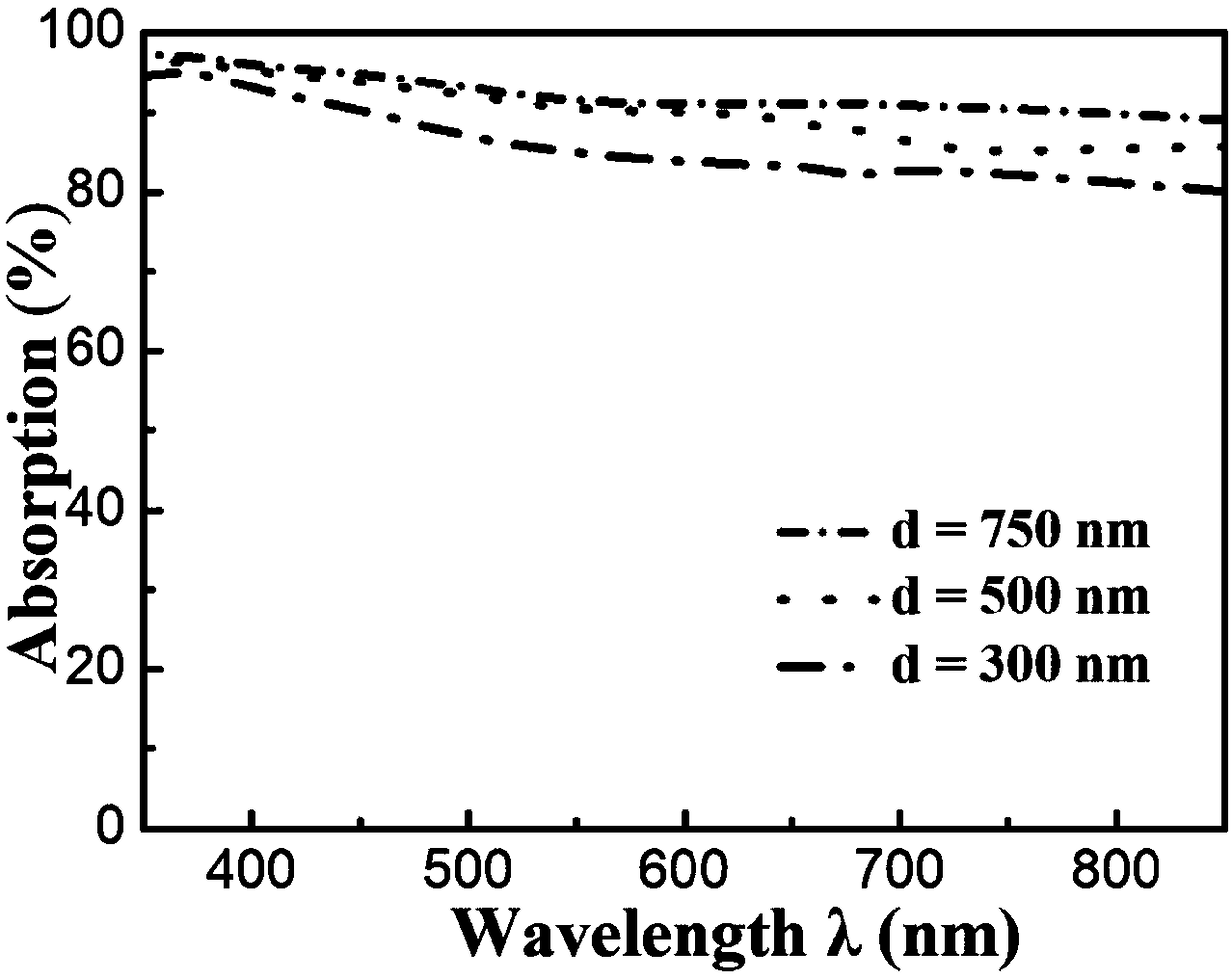

[0023] A monolayer film of polystyrene spheres was prepared on a glass slide as a substrate. The spheres we used were aqueous solution of polystyrene spheres produced by HugeBiotechnology Company, and the diameter of the spheres was d=300nm. The metal absorption layer / non-metal dielectric layer unit is deposited on the substrate by thermal evaporation, and the substrate is rotated so that the optimal angle between the normal and the deposition direction is 75°. Each metal absorption layer / non-metal dielectric layer unit sample The azimuth rotation angle of the stage increases by 65° each time, and there are 7 metal absorption layer / non-metal dielectric layer units in total, and the thickness of each layer of the alternate metal absorption layer / non-metal dielectric layer is optimized to 30nm. attached figure 1 It is a schematic structural diagram of an ultra-broadband absorber in the visible to near-infrared band of the present invention. ①-⑦ in the figure represent 7 metal a...

Embodiment 2

[0025] A monolayer film of polystyrene spheres was prepared on a glass slide as a substrate. The spheres we used were aqueous solution of polystyrene spheres produced by HugeBiotechnology Company, and the diameter of the spheres was d=500nm. The metal absorption layer / non-metal dielectric layer unit is deposited on the substrate by thermal evaporation, and the substrate is rotated so that the optimal angle between the normal and the deposition direction is 75°. Each metal absorption layer / non-metal dielectric layer unit sample The azimuth rotation angle of the stage increases by 65° each time, and there are 7 metal absorption layer / non-metal dielectric layer units in total, and the thickness of each layer of the alternate metal absorption layer / non-metal dielectric layer is optimized to 30nm. attached figure 1 It is a schematic structural diagram of an ultra-broadband absorber in the visible to near-infrared band of the present invention. ①-⑦ in the figure represent 7 metal a...

Embodiment 3

[0027] A monolayer film of polystyrene spheres was prepared on a glass slide as a substrate. The spheres we used were aqueous solution of polystyrene spheres produced by HugeBiotechnology Company, and the diameter of the spheres was d=750nm. The metal absorption layer / non-metal dielectric layer unit is deposited on the substrate by thermal evaporation, and the substrate is rotated so that the optimal angle between the normal and the deposition direction is 75°. Each metal absorption layer / non-metal dielectric layer unit sample The azimuth rotation angle of the stage increases by 65° each time, and there are 7 metal absorption layer / non-metal dielectric layer units in total, and the thickness of each layer of the alternate metal absorption layer / non-metal dielectric layer is optimized to 30nm. attached figure 1 It is a schematic structural diagram of an ultra-broadband absorber in the visible to near-infrared band of the present invention. figure 1 Middle ①-⑦ represent 7 metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com