Photo-etching machine coherence factor measuring method based on CCD imaging

A technology of coherence factor and measurement method, which is applied in the field of collaborative optimization design of lithography machine parameters, can solve the problems that the influence of photoresist processing process measurement results cannot be ruled out, and real-time measurement cannot be satisfied, so as to shorten the photosensitive time and reduce the experimental cost , the effect of correct positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

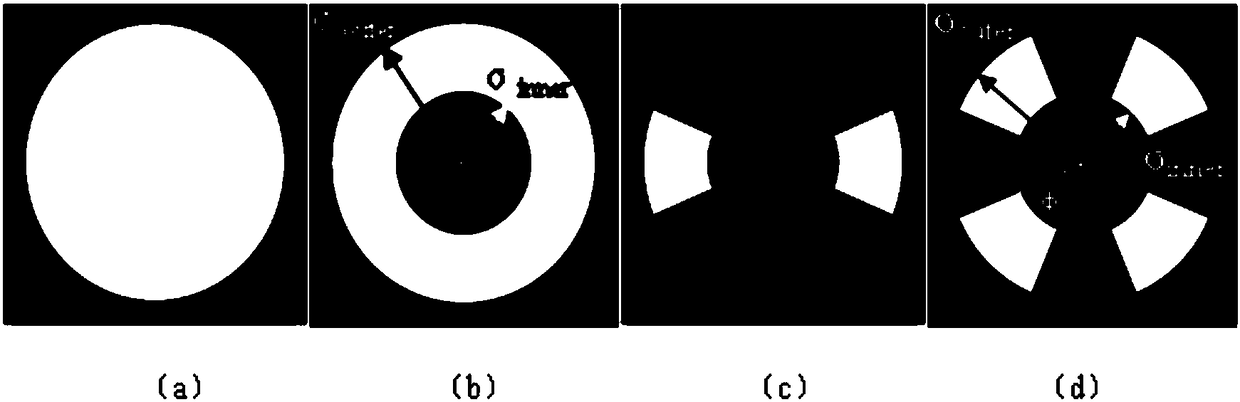

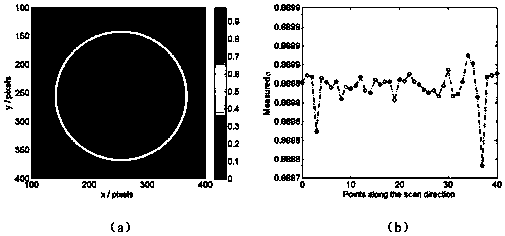

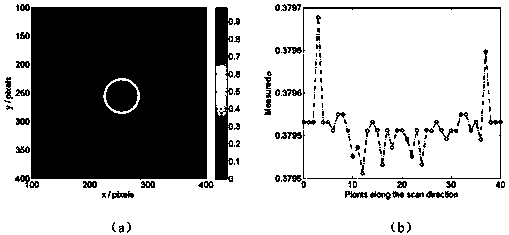

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and embodiments.

[0022] The illumination source of the projection exposure system of the lithography machine is imaged at the entrance pupil of the objective lens. The coherence factor σ is defined as the ratio of the diameter of the light source image on the entrance pupil surface of the objective lens to the aperture diameter of the objective lens, or defined as the numerical aperture of the illumination system and the numerical aperture of the projection objective lens Ratio. Expressed as:

[0023]

[0024] where NA ILLU is the numerical aperture of the illumination system, NA PL is the numerical aperture of the projection objective lens, such as figure 1 As shown, the light emitted by the light source 101 is transmitted to the projection objective lens 104 through the lens 102 and the mask 103, 105 is a silicon wafer, and 106 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com