Porous fibroin spinal marrow scaffold with directional releasing function as well as preparation method, preparation mold and application thereof

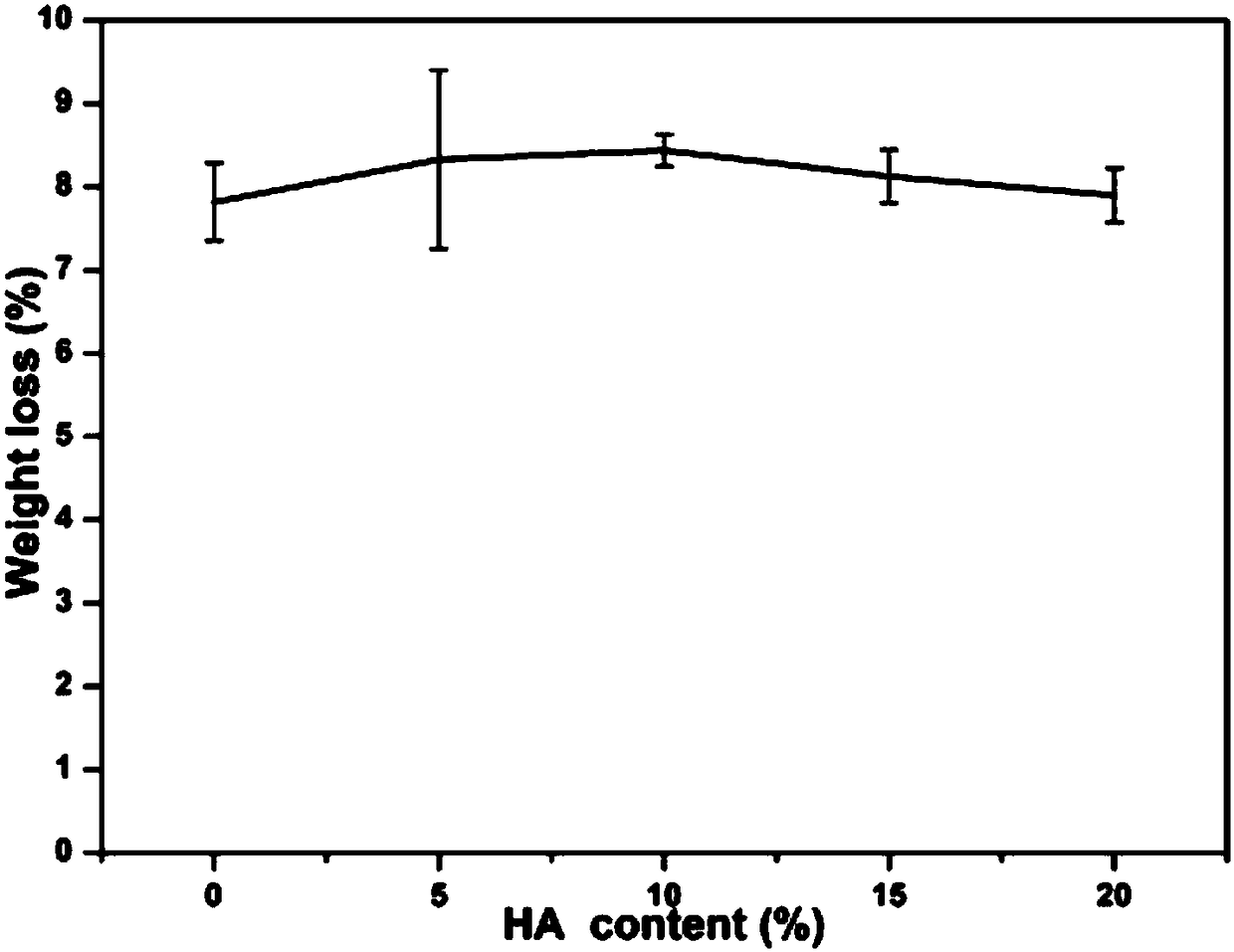

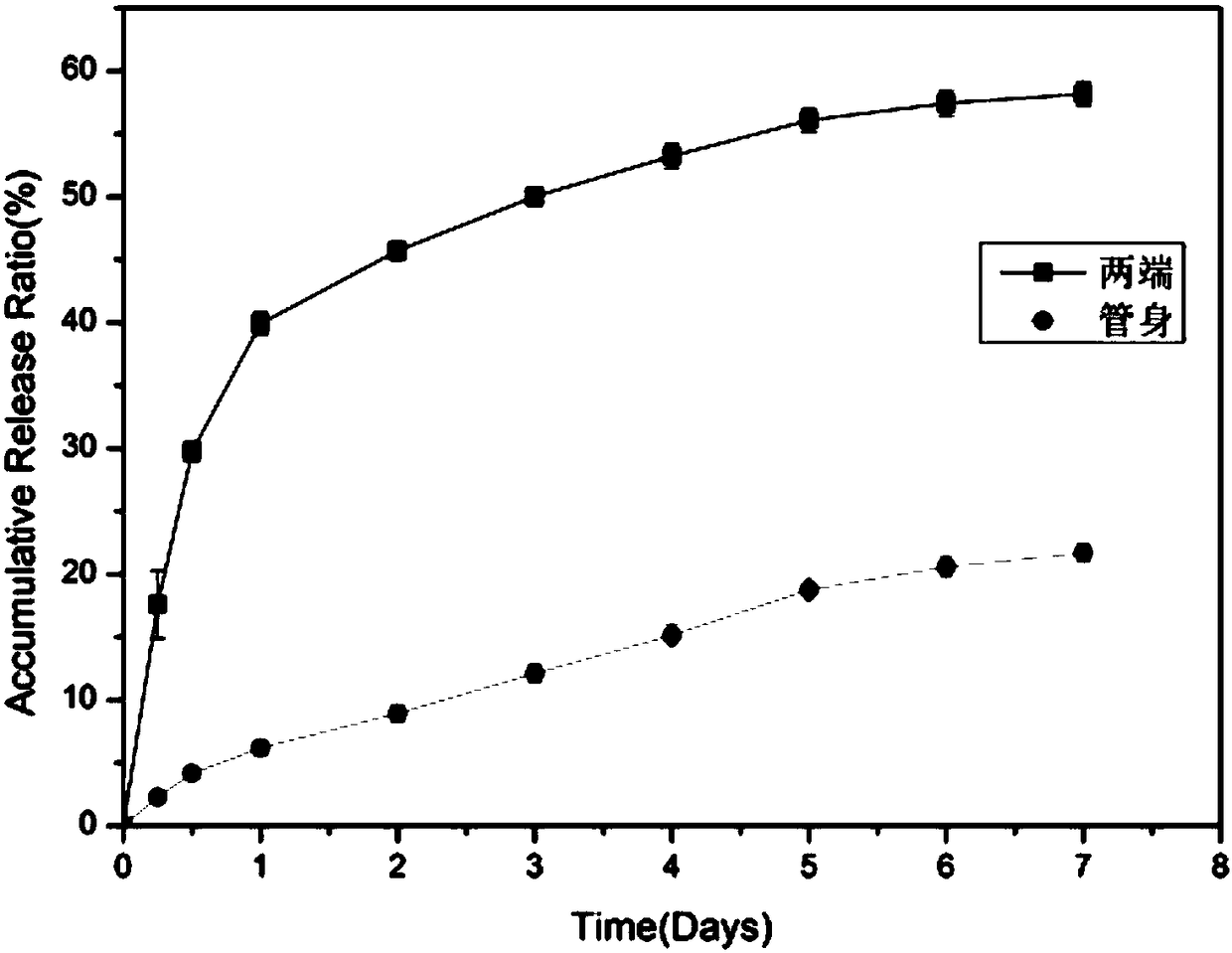

A technology of porous wire and spinal cord, applied in the field of spinal cord scaffolding, can solve the problems of complicated and time-consuming directional freezing operation, and achieve the effects of moderate water absorption and expansion rate, good pore connectivity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] 1. Preparation of silk fibroin aqueous solution

[0040] Take the pupa cocoon and add 0.02mol / L Na with 100 times its mass 2 CO 3 Boil the aqueous solution for 30 minutes, take it out, wring it out, and rinse with distilled water; repeat the above operation twice, dry in an oven at 60°C for 24 hours, and pull loose in the middle to obtain degummed silk; place the degummed silk in a 9.3mol / L LiBr aqueous solution , The mass ratio of degummed silk to 9.3mol / L LiBr aqueous solution is 1:5, keep at 60℃ until the degummed silk is completely dissolved, put it into a dialysis bag with a cut-off molecular weight of 8000-14000 Dalton, and dialyze with tap water at 4℃ for two days. Dialysis with deionized water at 4°C for one day (change the water every 1h on the first day, and every 2 hours for the next two days, and the time interval for changing water at night should not be too long). After dialysis, the solution is filtered through 8 layers of gauze and centrifuged to obtain the ...

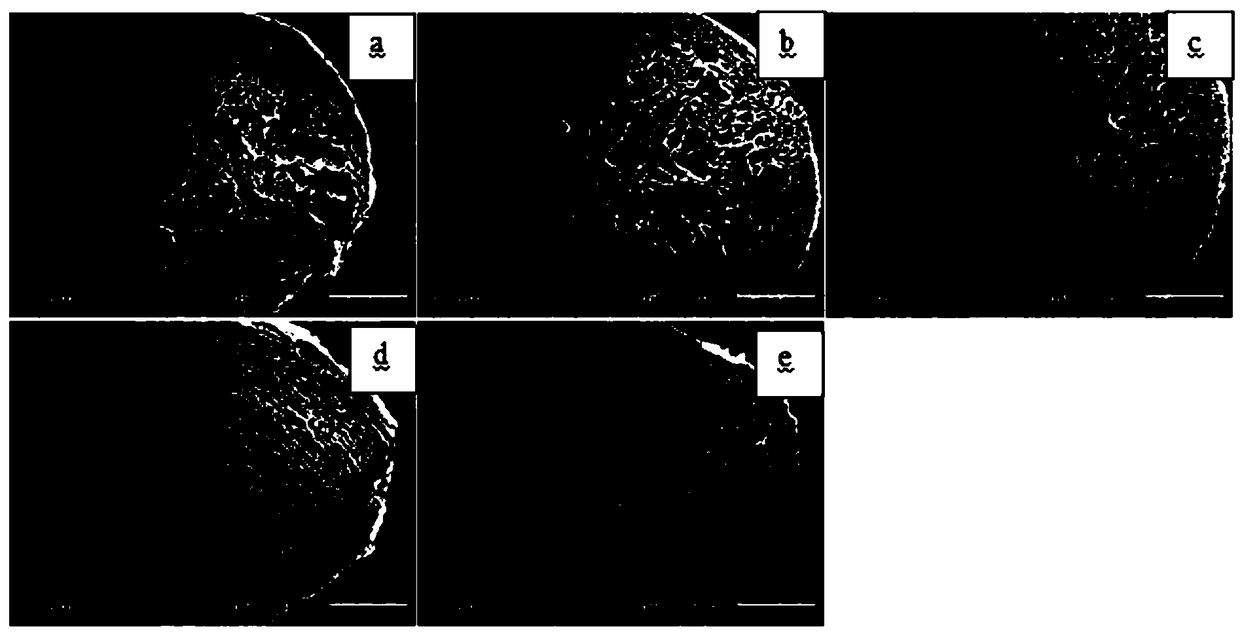

Embodiment 1

[0046] In step 1 of preparing the stent in Example 1, 20ml of a mixed solution with a total concentration of 5% and SF / HA=95:5 was prepared, and then 20% of EDC, 10% NHS, and 10% of the silk fibroin mass were added to the mixed solution. 0.012g MES (the content of EDC, NHS, MES is relative to the content of SF in the SF / HA mixed solution), fully stirred for 1h under ice bath. Use a syringe to inject it into the mold (the number of needles is 10), and freeze for 24 hours in a refrigerator at -80°C. The frozen sample was taken out from the mold and placed in a freeze dryer, and dried under reduced pressure for 48 hours to obtain a multi-channel SF / HA porous scaffold.

Embodiment 2

[0048] In step 1 of preparing the stent in Example 1, 20ml of the mixed solution with a total concentration of 5% and SF / HA=90:10 was prepared, and then EDC, 10% NHS, and 10% NHS, which accounted for 20% of the silk fibroin mass, were added to the mixed solution. 0.012g MES (the content of EDC, NHS, MES is relative to the content of SF in the SF / HA mixed solution), fully stirred for 1h under ice bath. Use a syringe to inject it into the mold (the number of needles is 10), and freeze for 24 hours in a refrigerator at -80°C. The frozen sample was taken out from the mold and placed in a freeze dryer, and dried under reduced pressure for 48 hours to obtain a multi-channel SF / HA porous scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com