Environmental-friendly preparation method for nanometer nickel

A nano-nickel and green technology, applied in the direction of nanotechnology, can solve the problems of hindering the effective progress of the reaction, immature production process, high production cost, etc., and achieve easy separation and collection, simple preparation method and process, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

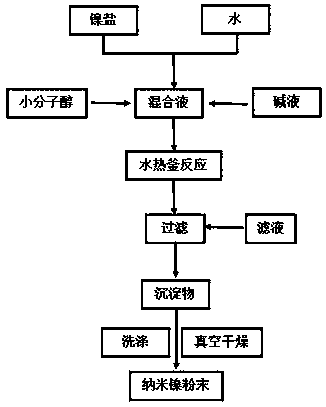

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve 0.004mol nickel sulfate pentahydrate in 25ml of water, stir to a homogeneous solution, add 25ml of ethanol, 25ml of NaOH solution with a concentration of 2.5mol / L, and stir for 1 hour.

[0020] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and in an oven for 170 O C for 36h and cooled to room temperature.

[0021] (3) The mixed liquid and solid in the reaction kettle are filtered to obtain filtrate and solid, and after the solid is washed with water and ethanol, 40 O C was vacuum dried for 24h to obtain nano nickel powder.

Embodiment 2

[0023] (1) Dissolve 0.003mol of nickel nitrate trihydrate in 25ml of water, stir to a homogeneous solution, add 15ml of ethanol and 15ml of 2.0mol / L NaOH solution, and stir for 2h.

[0024] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and in an oven at 190 O C for 20h and cooled to room temperature.

[0025] (3) The mixed liquid and solid in the reaction kettle are filtered to obtain filtrate and solid, and after the solid is washed with water and ethanol, 50 O C was vacuum dried for 24h to obtain nano nickel powder.

Embodiment 3

[0027] (1) Dissolve 0.002mol of nickel chloride in 25ml of water, stir to a homogeneous solution, add 15ml of ethanol and 10ml of 1.5mol / L NaOH solution, and stir for 2h.

[0028] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and in an oven for 210 O C for 16h and cooled to room temperature.

[0029] (3) The mixed liquid and solid in the reactor are filtered to obtain filtrate and solid, and after the solid is washed with water and ethanol, 30 O C was vacuum dried for 36h to obtain nano nickel powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com