Preparation method of composite phosphorus removing agent for sewage treatment

A compound phosphorus removal agent and sewage treatment technology, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Insufficient, poor phosphorus removal effect, etc., to achieve the effect of improving phosphorus removal effect, strong complex adsorption performance, and strong specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the preparation method of composite type dephosphorization agent

[0014] To prepare 150kg compound phosphorus removal agent, the steps are as follows:

[0015] S1 Weighing: Weigh 17kg Fe respectively 2 (SO 4 ) 3 , 15kgAlCl 3 ·6H 2 0, 6kg sodium hypochlorite, 2kg sodium chlorate, 3kg potassium permanganate and 1kg molecular weight are 200-15 million polyacrylamide, measure 106 liters of water in addition;

[0016] S2 feed: the Fe 2 (SO 4 ) 3 and AlCl 3 ·6H 2 0, be placed in the reactor, add water in the reactor, stir while adding, make compound dissolve, obtain ferric sulfate-aluminum chloride liquid; Add sodium hypochlorite, sodium chlorate, potassium permanganate successively, stir to dissolve;

[0017] S3 mixing: adding polyacrylamide to the mixed solution prepared in the above steps;

[0018] S4 emulsification: Start the machine and stir for 2-3 hours to prepare a mixed liquid of the compound phosphorus removal agent.

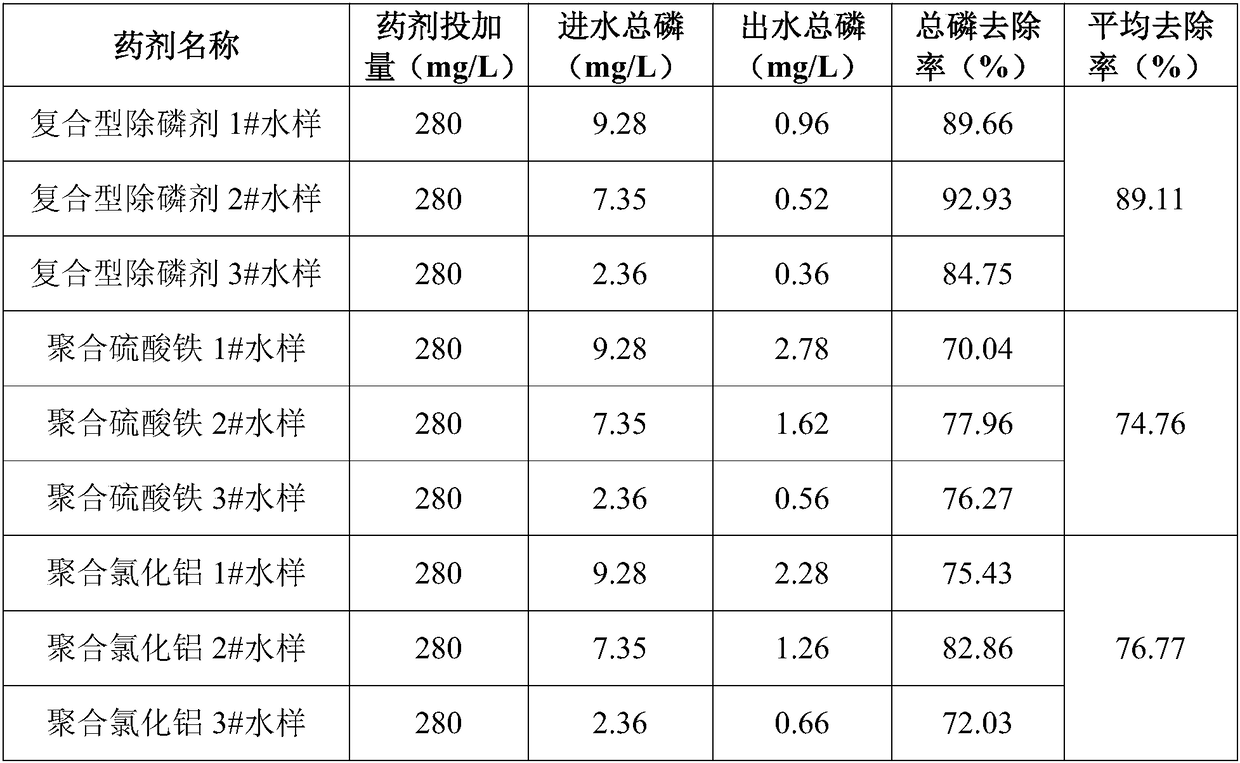

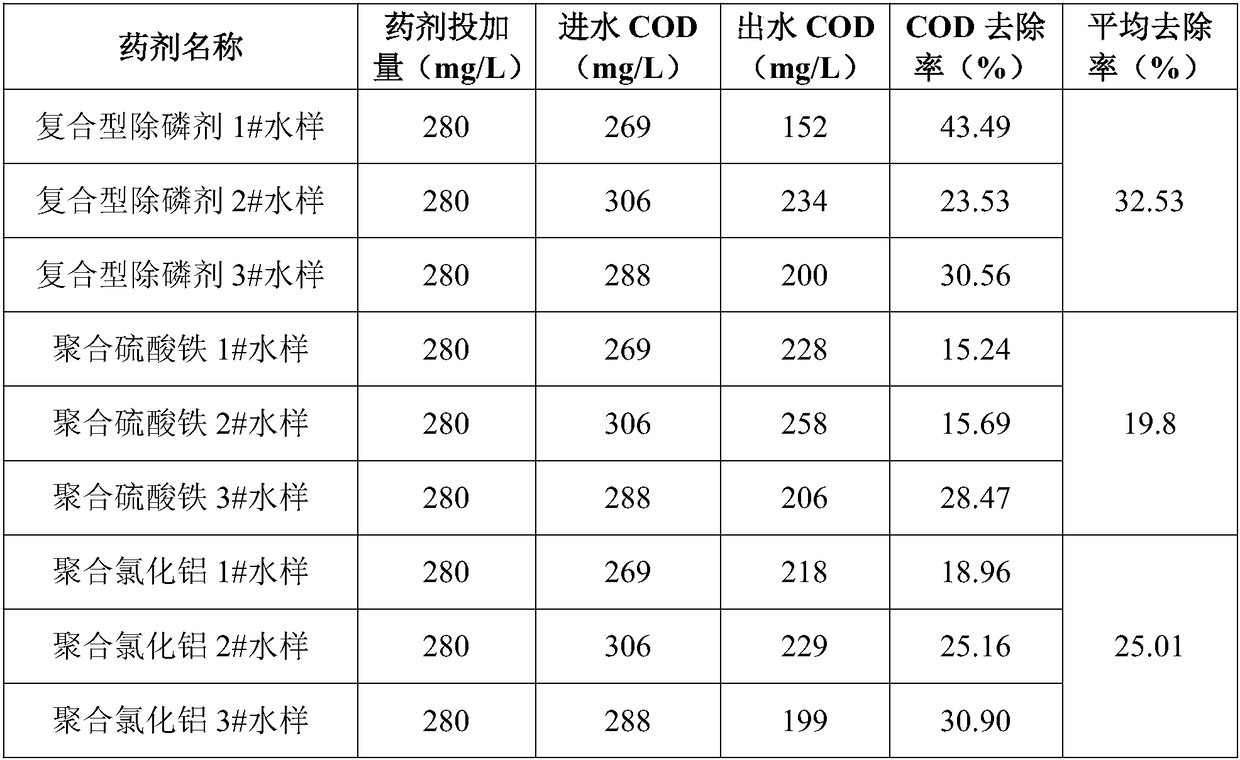

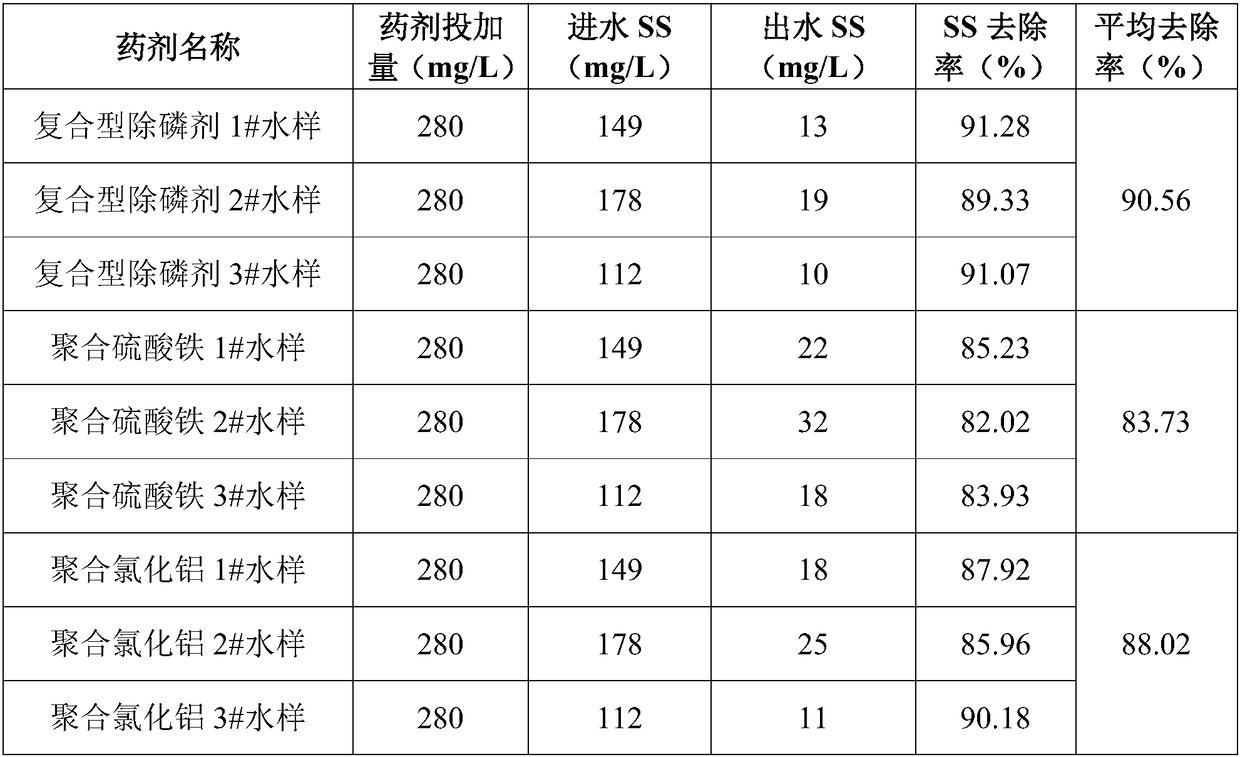

[0019] In order to f...

Embodiment 2

[0027] Embodiment 2: the application of composite phosphorus removal agent

[0028] a. When dosing at the front of the sewage treatment plant, the dosages of ferric sulfate, aluminum trichloride, sodium hypochlorite, sodium chlorate and potassium permanganate are 80-170g and 70-150g respectively in each cubic meter of sewage. 20-60g, 5-20g, 5-30g.

[0029] b. When dosing after the sewage treatment plant, the dosages of ferric sulfate, aluminum trichloride, sodium hypochlorite, sodium chlorate and potassium permanganate are 80-170kg and 70-150kg respectively in each cubic meter of sewage. 20-60kg, 5-20kg, 1-5g.

[0030] The dosing components in the two cases are the same, and the difference lies in the quality of potassium permanganate in the agent A. Therefore, a compound phosphorus removal agent containing a higher concentration (a) of potassium permanganate is prepared for pre-dosing of sewage treatment; a compound phosphorus removal agent containing a lower concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com