Violet gold glaze and burning method thereof

A technology of purple gold glaze and purple gold soil, which is applied in the field of purple gold glaze and its firing to achieve the effects of sweet taste, lower acidity, and good absorption by the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

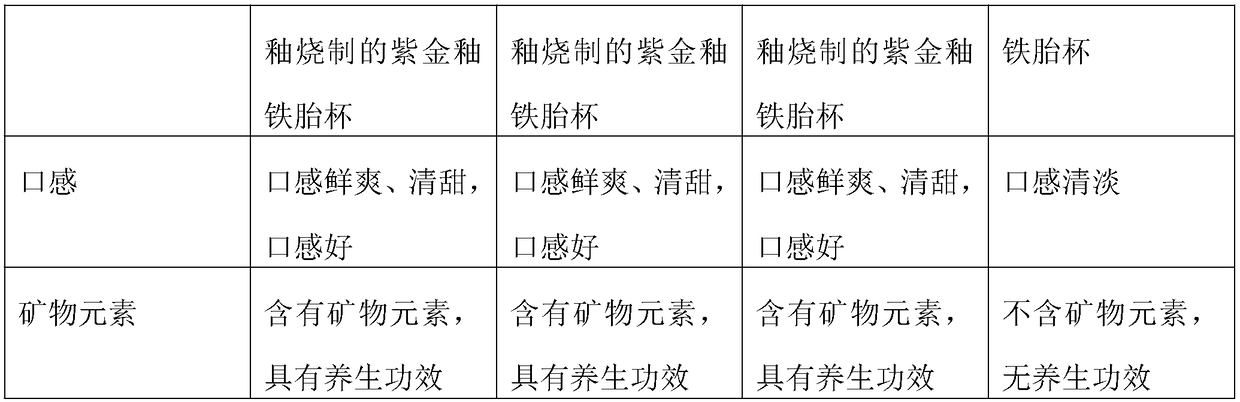

Embodiment 1

[0016] This purple gold glaze is made from the following raw materials by weight: 30 parts of Longquan original white glaze, 24 parts of purple gold clay, 9 parts of kaolin clay, and 28 parts of Longquan City thulium ore raw stone.

[0017] The firing method of the above-mentioned purple gold glaze is:

[0018] The first step is to mix the raw materials, uniformly mix the selected Longquan original white glaze, purple gold clay, kaolin, and Longquan thulium ore raw stone, wet ball mill for 70 hours, and then pass the milled raw materials through a 220-mesh sieve to obtain the glaze;

[0019] The second step is glazing. Add water to the obtained glaze to make a glaze slurry of 56 Baume degrees. Then take the porcelain blank and glaze the blank by dipping glaze. After the glaze is applied, place it in a cool and ventilated place for natural air drying. The time is 14 hours;

[0020] The third step is firing. Put the dried blanks into the kiln for firing. When firing, the temper...

Embodiment 2

[0023] This purple gold glaze is made from the following raw materials by weight: 35 parts of Longquan original white glaze, 25 parts of purple gold clay, 10 parts of kaolin, and 30 parts of raw thulium ore in Longquan City.

[0024] The firing method of the above-mentioned purple gold glaze is:

[0025] The first step is to mix the raw materials, uniformly mix the selected Longquan original white glaze, purple gold clay, kaolin, and Longquan thulium ore raw stone, wet ball mill for 70 hours, and then pass the milled raw materials through a 230-mesh sieve to obtain the glaze;

[0026] The second step is glazing. Add water to the obtained glaze to make a glaze slurry of 60 Baume degrees. Then take the plain porcelain embryo and apply glaze to the plain embryo by dipping glaze. After the glaze is applied, place it in a cool and ventilated place for natural air drying. The time is 15 hours;

[0027] The third step is firing. Put the dried blanks into the kiln for firing. When fi...

Embodiment 3

[0030] This purple gold glaze is made from the following raw material ratios by weight: 40 parts of Longquan original white glaze, 26 parts of purple gold clay, 11 parts of kaolin, and 35 parts of raw thulium ore in Longquan City.

[0031] The firing method of the above-mentioned purple gold glaze is:

[0032] The first step is to mix the raw materials, uniformly mix the selected Longquan original white glaze, purple gold clay, kaolin, and Longquan thulium ore raw stone, wet ball mill for 70 hours, and then pass the milled raw materials through a 240-mesh sieve to obtain the glaze;

[0033] The second step is glazing. Add water to the obtained glaze to make a glaze slurry of 64 Baume degrees. Then take the porcelain blank and glaze the blank by dipping glaze. After the glaze is applied, place it in a cool and ventilated place for natural air drying. The time is 16 hours;

[0034] The third step is firing. Put the dried blanks into the kiln for firing. When firing, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com