Carbon quantum dot and preparation method and application thereof

A carbon quantum dot and reaction technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of complex operation, high energy consumption, unsuitable for industrial production, etc., and achieve simple reaction process , reduce production costs, improve the effect of friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of carbon quantum dots, comprising the following steps:

[0026] Mixing glucose, heteropoly acid and water to obtain a reaction mixture;

[0027] The reaction mixture is subjected to hydrothermal reaction to obtain carbon quantum dots.

[0028] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0029] The invention mixes glucose, heteropoly acid and water to obtain a reaction mixture. In the present invention, the heteropoly acid preferably includes one or more of Keggin type heteropoly acid, Dawson type heteropoly acid, absence type heteropoly acid and substitution type heteropoly acid; more preferably Keggin type heteropoly acid Polyacid, Dawson type heteropolyacid, vacancy type heteropolyacid and substitution type silicotungstic acid, silicomolybdic acid, phosphotungstic acid, phosphomolybdic acid, vanadium...

Embodiment 1

[0052] Add 50mL of water to the mixture of 0.1g of anhydrous glucose and 0.1g of 12-phosphotungstic acid, and sonicate for 30min to obtain a reaction mixture;

[0053] The reaction mixture was added into a 100 mL polytetrafluoroethylene autoclave, heated to 190° C. at a heating rate of 5° C. / min, and hydrothermally treated for 10 hours. Naturally cool the reactor to room temperature, extract the product three times with ether, filter the obtained water phase through a filter membrane with a pore size of 0.22 μm, and then dialyze the filtrate with a dialysis membrane with a molecular weight cut-off of 1000 Da for 72 hours, and replace the water every 12 hours . Dry the dialyzed liquid at 70° C. until completely dry to obtain carbon quantum dots.

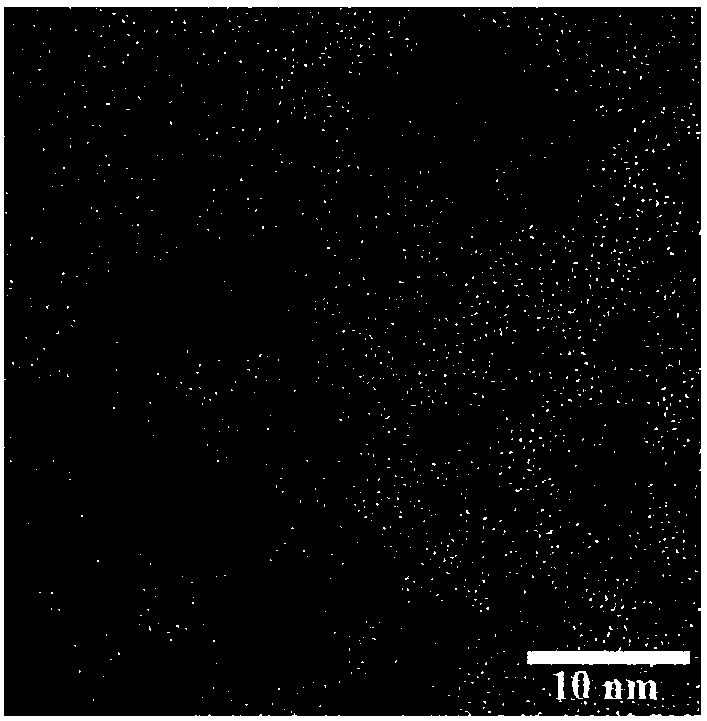

[0054] By transmission electron microscopy detection of the carbon quantum dots, as figure 1 As shown, the size range of the above-mentioned carbon quantum dots is 4.5-6.2nm;

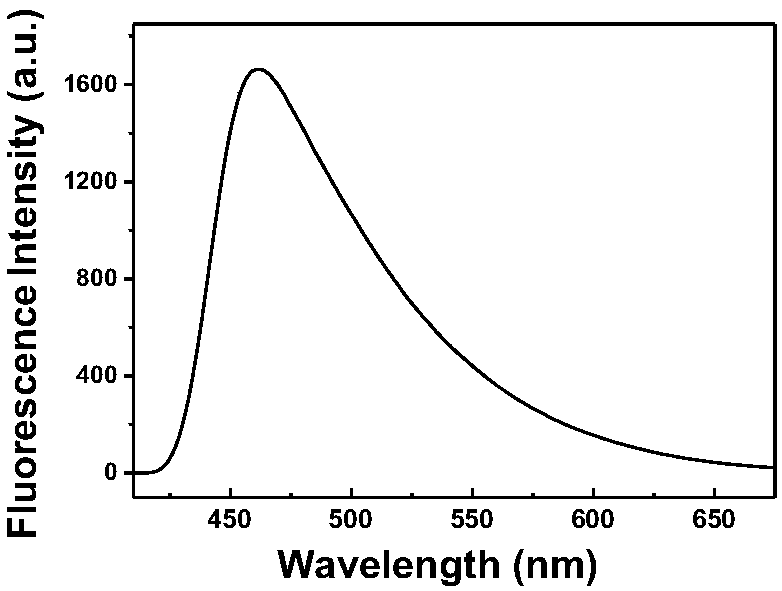

[0055] By testing the fluorescence emission of the car...

Embodiment 2

[0058] Add 50mL of water to the mixture of 1g of anhydrous glucose and 1g of 12-phosphotungstic acid, and sonicate for 30min to obtain a reaction mixture;

[0059] The reaction mixture was added into a 100 mL polytetrafluoroethylene autoclave, heated to 170° C. at a heating rate of 5° C. / min, and hydrothermally treated for 10 hours. Cool the reaction kettle to room temperature naturally, extract the product repeatedly with ether three times, filter the obtained water phase through a filter membrane with a pore size of 0.22 μm, and then dialyze the filtrate with a dialysis membrane with a molecular weight cut-off of 1000 Da for 72 hours, and replace it every 12 hours water. Dry the dialyzed liquid at 70° C. until completely dry to obtain carbon quantum dots.

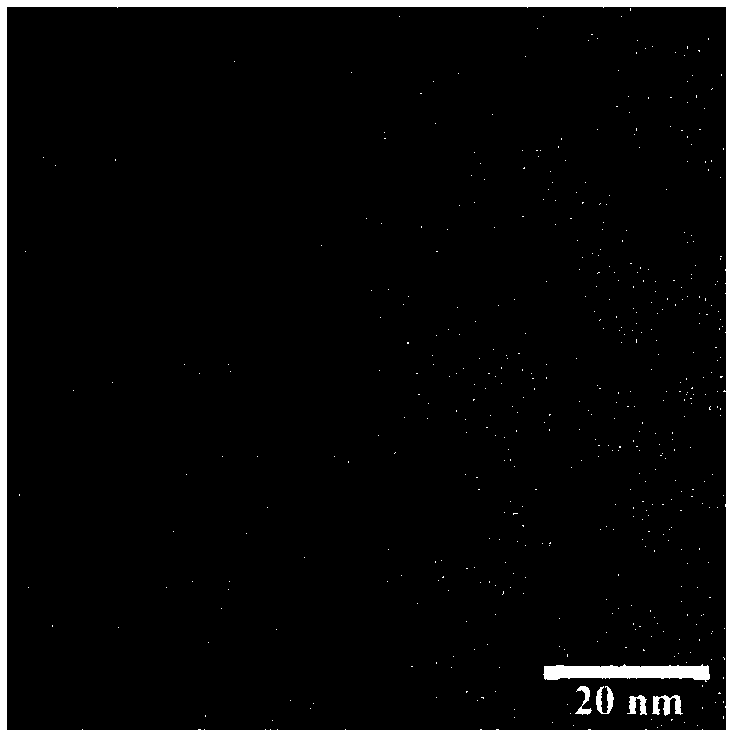

[0060] Through transmission electron microscopy (TEM) detection of the carbon quantum dots, such as image 3 As shown, the size range of the above-mentioned carbon quantum dots is 5.2-6.5nm;

[0061] By testing the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com