Pitaya stem extract, preparation method and applications thereof

A technology of pitaya stem and extract, applied in the field of pitaya stem extract, can solve problems such as unclear effect, skin thinning, pigmentation, etc., and achieves the advantages of simple extraction and separation operation, improved product quality, and enhanced capillary circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

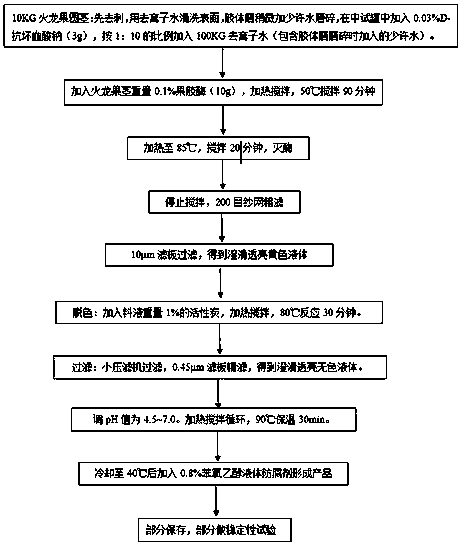

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of pitaya stem extract.

[0031] (a) Weigh 10 kg of the cleaned and thorned dragon fruit stem, wash its surface with deionized water and place it in a colloid mill. Deionized water; Add the D-sodium ascorbate of dragon fruit stem weight 0.03%, add the cellulase of dragon fruit stem weight 0.06%, wherein cellulase and deionized water are diluted by the mass ratio of 1:50; In reaction Stir and extract at a temperature of 40 °C and a stirring speed of 50 r / min for 120 min; (b) heat up to 70 °C and stir for 30 min for sterilization; stop heating, cool down to 20 °C with water circulation, use 60-mesh gauze for coarse filtration; take the filtrate , use a filter plate with a pore size of 1 μm for fine filtration; (c) add 0.5% activated carbon of the obtained filtered dragon fruit stem extract, and stir for 20 min at a reaction temperature of 70 °C; stop heating , the water is circulated and cooled to 20 ℃, and filtered with a filter plate with ...

Embodiment 2

[0032] Embodiment 2: the preparation of pitaya stem extract.

[0033] (a) Weigh 10 kg of the cleaned and thorned pitaya stem, wash its surface with deionized water and place it in a colloid mill. After the colloid mill is slightly ground with deionized water, add 20 Deionized water; add the D-sodium ascorbate of dragon fruit stem weight 0.03%, add the pectinase of dragon fruit stem weight 0.15%, pectinase and deionized water are diluted by the mass ratio of 1:60; At reaction temperature Stir and extract for 60 min at 60 °C with a stirring speed of 100 r / min; (b) heat up to 100 °C and stir for 15 min for sterilization; stop heating, cool to 50 °C with water circulation, use 150-mesh gauze for coarse filtration; take the filtrate , use a filter plate with a pore size of 8 μm for fine filtration; (c) add 2.0% activated carbon of the obtained filtered dragon fruit stem extract, and stir for 60 min at a reaction temperature of 90 °C; stop heating , the water was circulated and coo...

Embodiment 3

[0034] Embodiment 3: the preparation of pitaya stem extract.

[0035] (a) Weigh 10 kg of the cleaned and thorned dragon fruit stem, wash its surface with deionized water and place it in a colloid mill. After the colloid mill is slightly ground with deionized water, add 13 Deionized water; add the D-sodium ascorbate of dragon fruit stem weight 0.03%, add the cellulase of dragon fruit stem weight 0.08%, wherein cellulase and deionized water are diluted by the mass ratio of 1:70; Stir and extract at a temperature of 45 °C and a stirring speed of 80 r / min for 80 min; (b) heat up to 80 °C and stir for 25 min for sterilization; stop heating, cool down to 40 °C with water circulation, use 100-mesh gauze for coarse filtration; take the filtrate , use a filter plate with a pore size of 5 μm for fine filtration; (c) add 1.5% activated carbon of the obtained filtered dragon fruit stem extract, and stir for 40 min at a reaction temperature of 85 °C; stop heating , the water is circulated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com