Transition metal and nitrogen-co-doped carbon composite for formaldehyde purification and preparation method of composite

A technology of carbon composite materials and transition metals, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., to achieve the effect of overcoming harsh conditions, low cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

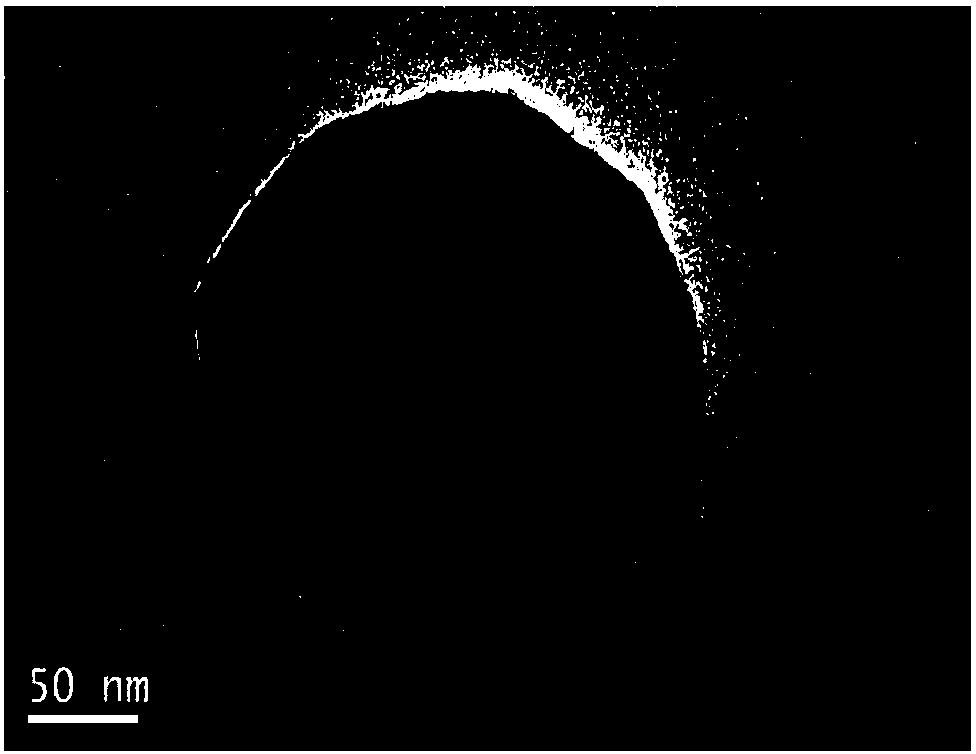

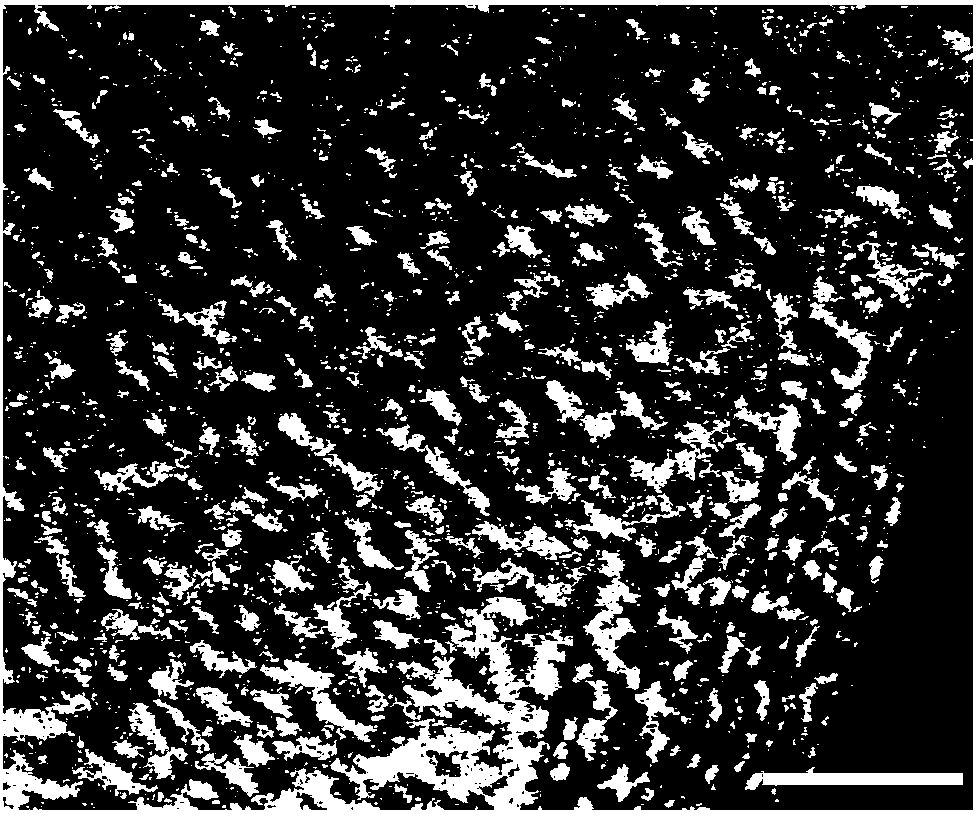

[0019] Example 1 Preparation of transition metal and nitrogen co-doped carbon composite

[0020] Mix 0.45 g of cobalt nitrate solid, 5 g of dimethylimidazole solid and 50 ml of water, heat and stir at 40°C for 10 h, then wash and vacuum dry to obtain a solid powder. The prepared solid powder in N 2 The transition metal and nitrogen co-doped carbon composites were obtained by calcining at 300 ℃ for 4 h under atmosphere.

Embodiment 2

[0021] Example 2 Preparation of transition metal and nitrogen co-doped carbon composite

[0022] Mix 0.9 g of cobalt nitrate solid, 11 g of dimethylimidazole solid, and 100 ml of water, stir at 60°C for 30 h, wash with methanol, and dry in vacuo to obtain a solid powder. The prepared solid powder was calcined at 500°C for 5 h under Ar atmosphere to obtain transition metal and nitrogen co-doped carbon composites.

Embodiment 3

[0023] Example 3 Preparation of transition metal and nitrogen co-doped carbon composite

[0024] Mix 0.9 g of cobalt nitrate solid, 16 g of dimethylimidazole solid and 150 ml of water, heat and stir at 70°C for 2 h, then wash and vacuum dry to obtain a solid powder. The prepared solid powder in N 2 Calcined at 600°C for 6h under atmosphere to obtain transition metal and nitrogen co-doped carbon composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com