Method for adopting high-efficiency and low-loss solvent to carry out absorbing treatment on ethyl acetate

An ethyl acetate, low-loss technology, applied in gas treatment, separation methods, carboxylate preparation, etc., can solve the problems of ethyl acetate waste gas pollution, difficult treatment, strong toxicity, etc., to solve the problem of difficult waste gas treatment , Good recycling effect, high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

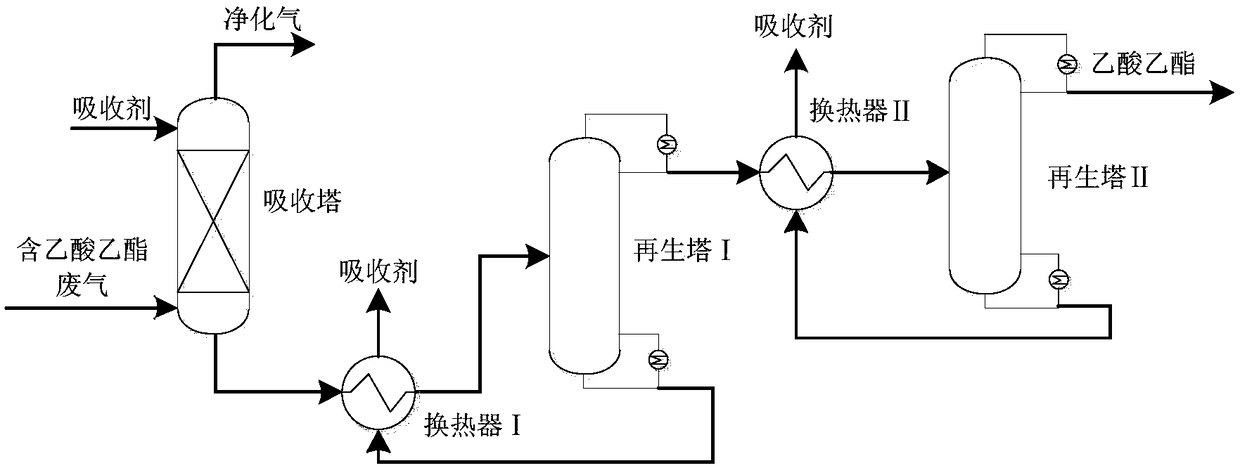

[0028] A method of absorbing ethyl acetate using a high-efficiency and low-damage solvent in this embodiment, the flow chart of its absorption process is as follows figure 1 As shown, the process consists of absorption tower, heat exchanger I, heat exchanger II, regeneration tower I, regeneration tower II and pipe fittings. A pipe-trough distributor is arranged in the main body of the absorption tower, and liquid level gauges, temperature sensors and pressure sensors are arranged on the tower body along the height direction of the absorption tower. The specific absorption treatment steps are as follows:

[0029] Waste gas containing ethyl acetate (from the coating process of a factory in Ningbo City, Zhejiang Province containing ethyl acetate waste gas, the flow rate is 4000m 3 / h, the temperature is 35°C, the concentration of ethyl acetate is 500g / m 3 ) first enters the absorption tower from the gas feed port of the lower section of the absorption tower, and flows from botto...

Embodiment 2

[0031] A method of absorbing ethyl acetate using a high-efficiency and low-damage solvent in this embodiment, the flow chart of its absorption process is as follows figure 1 As shown, the specific absorption treatment steps are as follows:

[0032] Waste gas containing ethyl acetate (from the coating process of a factory in Ningbo City, Zhejiang Province containing ethyl acetate waste gas, the flow rate is 4000m 3 / h, the temperature is 35°C, the concentration of ethyl acetate is 500g / m 3 ) first enters the absorption tower from the gas feed port of the lower section of the absorption tower, and flows from bottom to top in the absorption tower. The packing layer height of the absorption tower is 5m, the tower height is 8m, and the tower diameter is 0.8m; at the same time, the N,N-dimethylacetamide absorbent with a flow rate of 250kg / h enters from the upper section of the absorption tower. , from top to bottom with the waste gas countercurrent contact in the absorption tower ...

Embodiment 3

[0034] A method of absorbing ethyl acetate using a high-efficiency and low-damage solvent in this embodiment, the flow chart of its absorption process is as follows figure 1 As shown, the specific absorption treatment steps are as follows:

[0035] Waste gas containing ethyl acetate (from the coating process of a factory in Ningbo City, Zhejiang Province containing ethyl acetate waste gas, the flow rate is 4000m 3 / h, the temperature is 35°C, the concentration of ethyl acetate is 500g / m 3 ) first enters the absorption tower from the gas feed port of the lower section of the absorption tower, and flows from bottom to top in the absorption tower. The packing layer height of the absorption tower is 5m, the tower height is 8m, and the tower diameter is 0.8m; meanwhile, the 1,4-butyrolactone absorbent with a flow rate of 250kg / h enters from the upper section of the absorption tower. From top to bottom, it contacts with the waste gas countercurrently in the absorption tower for ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com