Technique for recycling potassium feldspar from potassium-rich slate

A process method, technology of potassium-rich slate, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as low potassium content in ore, high roasting slag content, and impact, and achieve optimal combination ratio, Reduce the amount of slagging and reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

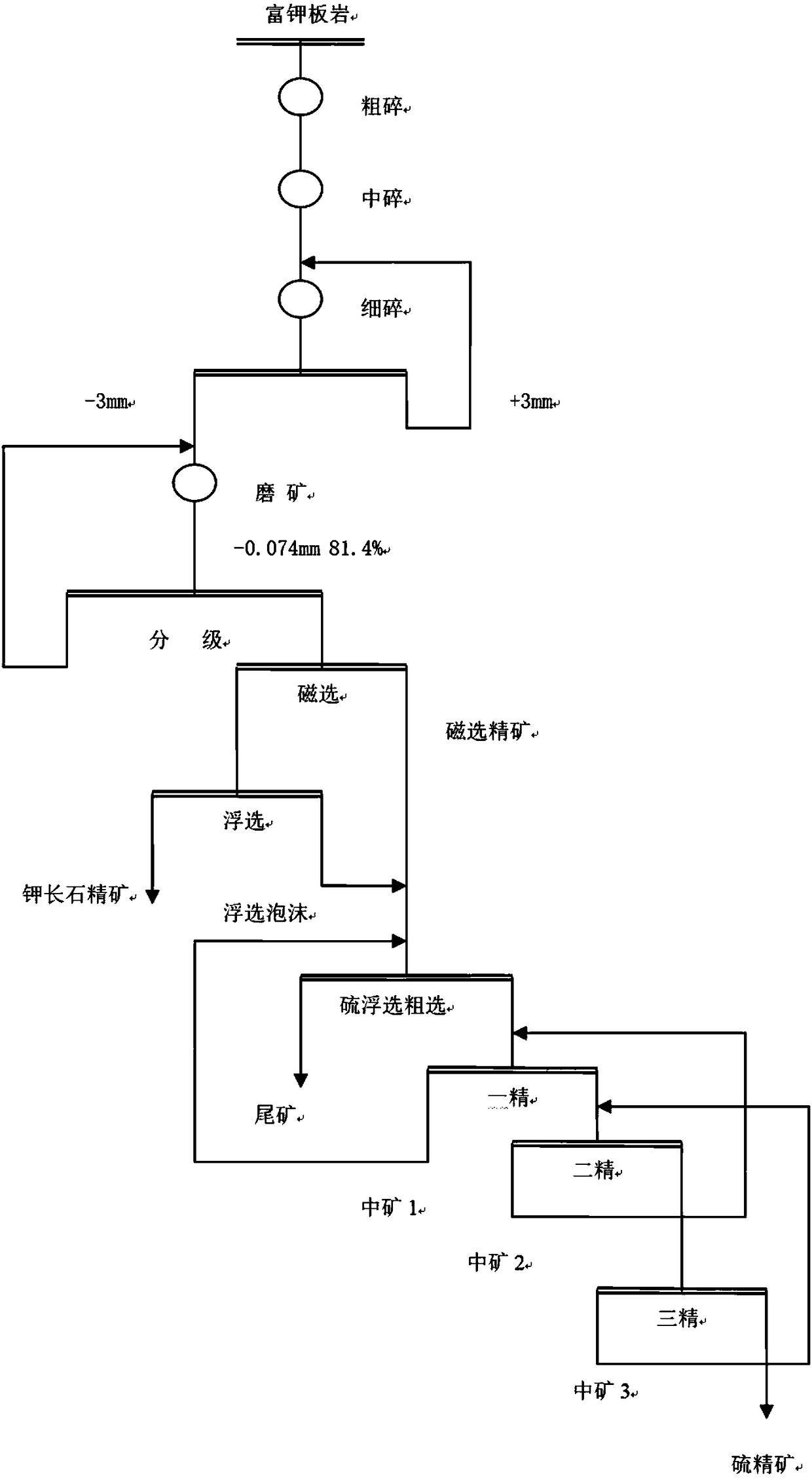

[0052] The technological method of reclaiming potassium feldspar in embodiment, potassium-rich slate

[0053] Step 1. Processing of raw materials

[0054] The potassium-rich slate is crushed in three stages of coarse crushing, medium crushing and fine crushing, and the particle size of the crushed product is -3mm;

[0055] Step 2. Grinding

[0056] Grinding the above crushed products, the particle size of the grinding products is -0.074mm, accounting for 81.4%;

[0057] Step 3, carrying out a section of magnetic separation on the above-mentioned grinding product under the condition of a magnetic field strength of 179.1kA / m, to obtain magnetic separation concentrate and magnetic separation tailings;

[0058] After testing, the sulfur content in the magnetic separation concentrate is 10.41%, and the recovery rate is 44.50%; the potassium oxide content in the magnetic separation tailings is 10.70%, the potassium oxide recovery rate is 95.33%, and the sulfur content is 1.41%;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com