Inert closed-pore perlite fire-insulation heat-insulation wallboard

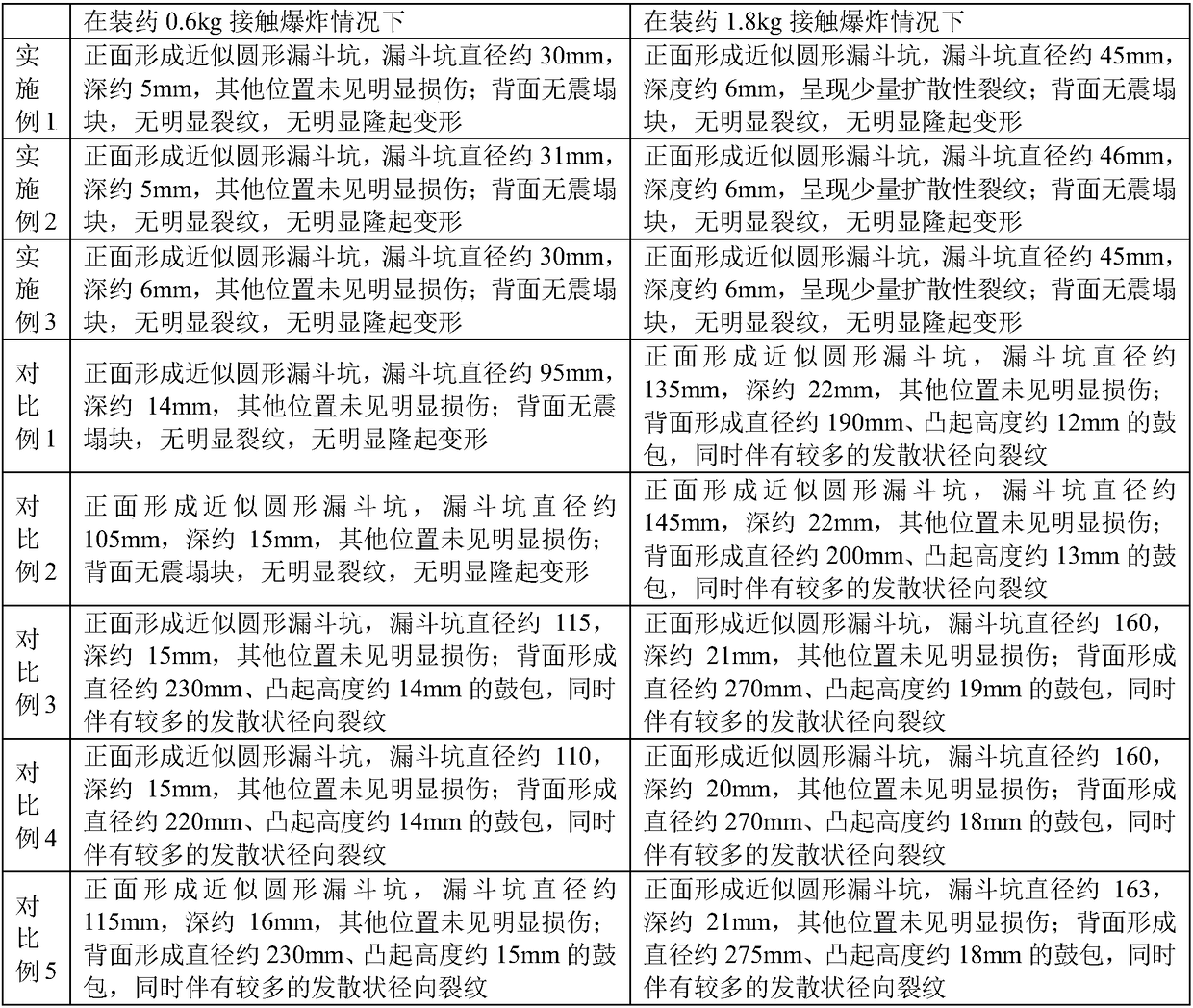

A technology of closed-cell perlite and wall panels, which is applied in the direction of fireproof coatings, etc., can solve the problems of heavy foamed cement composite panels, insufficient structural strength, and restrictions on the application of prefabricated houses, and achieve high tear resistance , reduce moisture sensitivity, excellent engineering mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

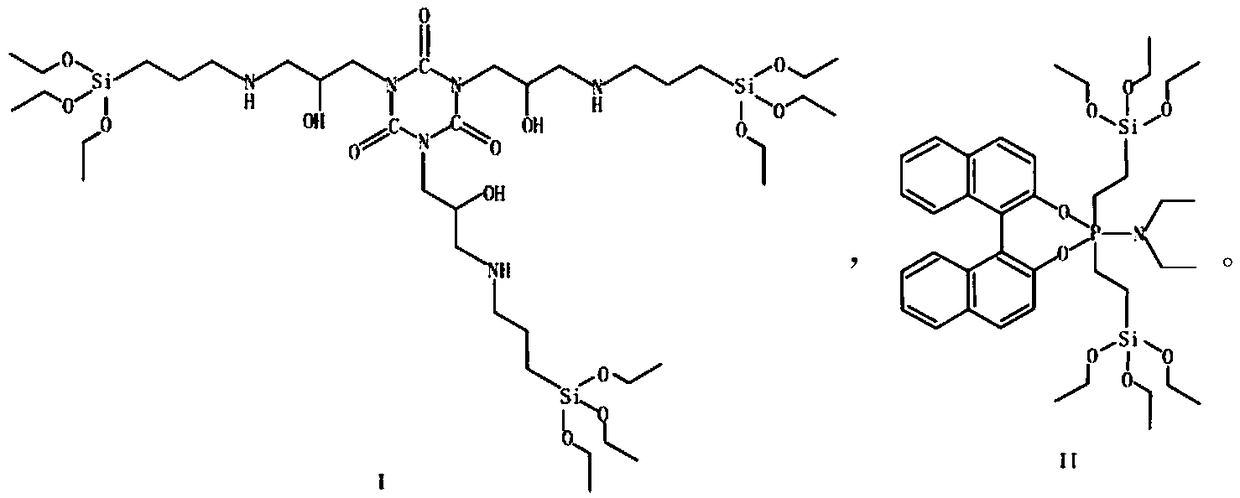

[0026] After stirring 100g of isophorone diisocyanate and 30g of polypropylene glycol at 30°C for 1 hour, add 15g of amino-terminated polyether D2000 and 0.1g of isopropanol, and react at 30°C for 0.75 hours to obtain polyurea prepolymer.

preparation example 2

[0028] After stirring 100g of isophorone diisocyanate and 35g of polypropylene glycol at 35°C for 0.5 hours, add 12g of amino-terminated polyether D3500 and 0.5g of isopropanol, and keep warm at 35°C for 0.5 hours to obtain polyurea prepolymer.

preparation example 3

[0030] After stirring 100g of isophorone diisocyanate and 40g of polypropylene glycol at 32°C for 0.75 hours, add 10g of amino-terminated polyether D5000 and 0.3g of isopropanol, and keep warm at 32°C for 1 hour to obtain polyurea prepolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com