Preparation technology of thermal barrier coating of blade of aviation engine

A technology of aero-engine and thermal barrier coating, applied in the field of laser applications, to achieve the effect of improving bonding strength and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

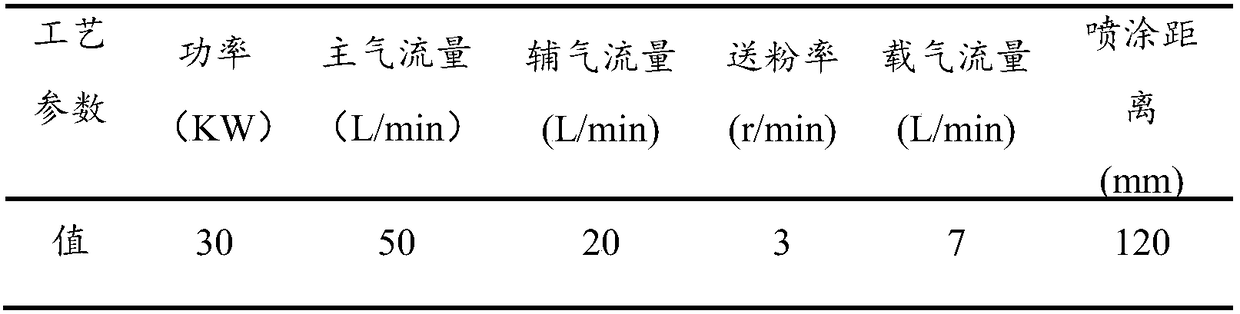

[0046] (1) CoCrAlY coating was prepared by plasma spraying on 5 samples of nickel-based superalloy GH4586 as the bonding layer of thermal barrier coating. The preparation process parameters are shown in Table 1. Thickness 130μm.

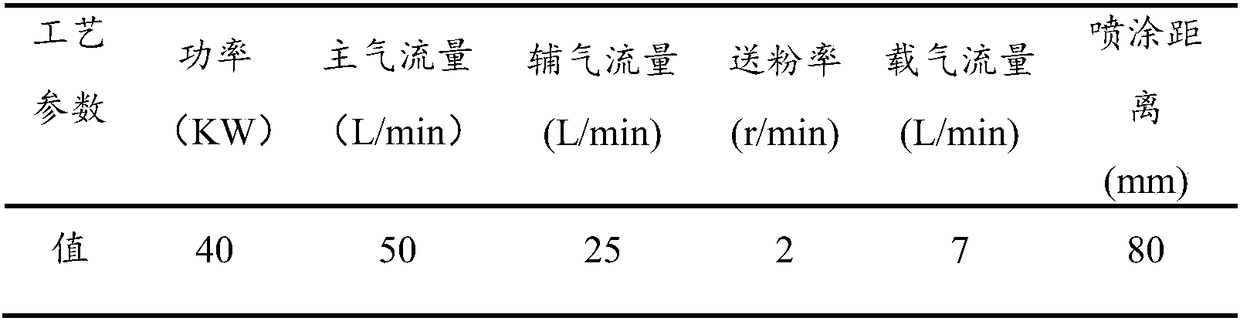

[0047] (2) Spray 8YSZ coating on the bonding layer, the specific process parameters are shown in Table 2. The thickness is 52 μm.

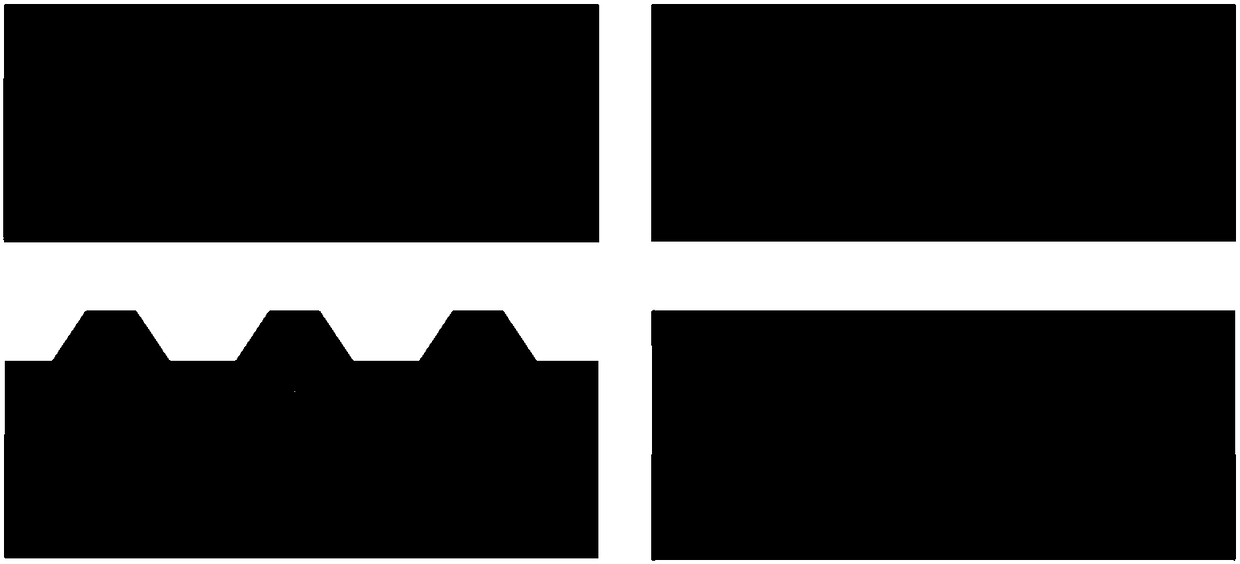

[0048] (3) The surface of the ceramic layer is pre-treated by laser etching using a Nd:YAG laser. The specific process parameters are as follows: the working wavelength is 1064nm, the pulse width is 10ps, the pulse energy is 60J, the focal length of the focusing lens is 250mm, and the scanning speed of the galvanometer is 15mm / s. The distributed isosceles trapezoidal groove structure has the following dimensions: the length of the upper base is 101.6 μm, the length of the lower base is 50.5 μm, and the height is 50.8 μm. The pitch of the isosceles trapezoidal grooves is about 150.3 μm.

[0049] (4) Plasma spraying was...

Embodiment 2

[0055] (1) CoCrAlY coating was prepared by plasma spraying on 5 samples of nickel-based superalloy GH4586 as the bonding layer of thermal barrier coating. The preparation process parameters are shown in Table 1. The thickness is 131 μm.

[0056] (2) Spray 8YSZ coating on the bonding layer, the specific process parameters are shown in Table 2. The thickness is 52 μm.

[0057] (3) The surface of the ceramic layer is pre-treated by laser etching using a Nd:YAG laser. The specific process parameters are as follows: the working wavelength is 1060nm, the pulse width is 10ps, the pulse energy is 70J, the focal length of the focusing lens is 250mm, and the scanning speed of the galvanometer is 20mm / s. The isosceles trapezoidal groove structure distributed in parallel, its size is: the length of the upper base is 100.3 μm, the length of the lower base is 50.7 μm, and the height is 50.6 μm. The pitch of the isosceles trapezoidal grooves is about 150.5 μm.

[0058] (4) Plasma spraying...

Embodiment 3

[0064] (1) CoCrAlY coating was prepared by plasma spraying on 5 samples of nickel-based superalloy GH4586 as the bonding layer of thermal barrier coating. The preparation process parameters are shown in Table 1. The thickness is 138 μm.

[0065] (2) Spray 8YSZ coating on the bonding layer, the specific process parameters are shown in Table 2. The thickness is 51 μm.

[0066] (3) The surface of the ceramic layer is pre-treated by laser etching using a Nd:YAG laser. The specific process parameters are as follows: the working wavelength is 532nm, the pulse width is 10ps, the pulse energy is 80J, the focal length of the focusing lens is 250mm, and the scanning speed of the galvanometer is 30mm / s. The isosceles trapezoidal groove structure distributed in parallel, its size is: the length of the upper base is 100.2 μm, the length of the lower base is 50.3 μm, and the height is 50.4 μm. The pitch of the isosceles trapezoidal grooves is about 105.5 μm.

[0067] (4) Plasma spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com