Preparation method and application of self-assembled thrombin esterified microporous hemostatic starch

A technology of microporous starch and esterified microporous, which is applied in the fields of application, pharmaceutical formula, medical science, etc., can solve the problem of no effect for a large amount of bleeding, achieve good biocompatibility, improve hydrophilicity, and improve surface load. The effect of potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

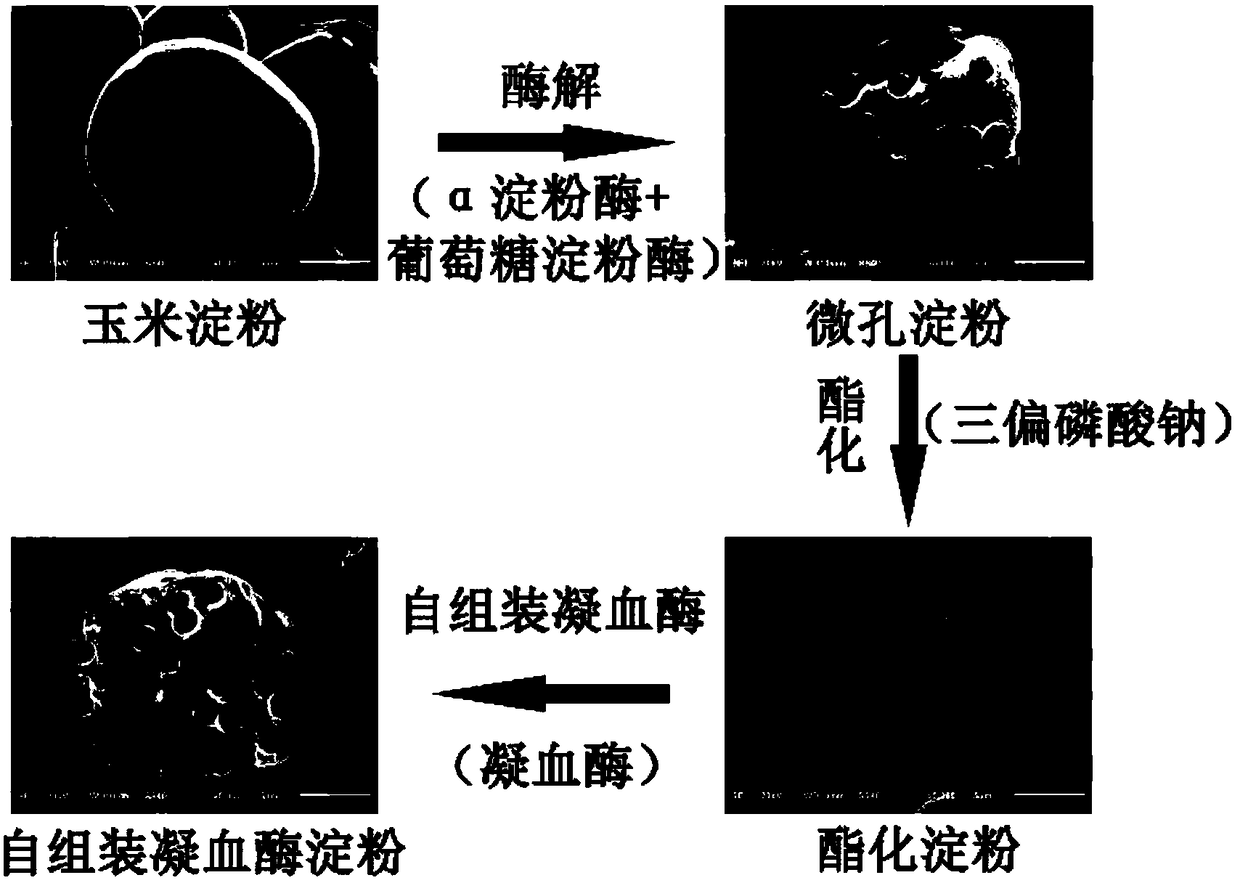

[0029] A method for preparing self-assembled thrombin esterified microporous hemostatic starch, prepared by the following steps:

[0030] In the first step, 40g of cornstarch is added to 200ml of sodium acetate buffer solution with pH=4, the mixture ratio of α-amylase and glucoamylase contained therein is 1:4, and the ratio of enzyme and starch is 1:20 (w / w), stirred at 25°C at a speed of 150rpm / min for 24h, suction filtered to obtain starch filter residue, dried at 50°C, and ground into powder.

[0031] In the second step, add 10 grams of microporous starch to 100 ml of distilled water, then add 1 g of anhydrous sodium carbonate and 2 g of sodium trimetaphosphate, bathe in water for 48 hours at 25 ° C, filter the sample solution obtained by suction, and put it under 50 ° C Dried and ground into powder.

[0032] The third step is to add 0.2g of the esterified microporous starch obtained by the reaction to 4ml of thrombin aqueous solution, place it at 4°C and continue to vibra...

Embodiment 2

[0034] A method for preparing self-assembled thrombin esterified microporous hemostatic starch, prepared by the following steps:

[0035] In the first step, 40g of cornstarch is added to 200ml of sodium acetate buffer solution with pH=6, the mixture ratio of α-amylase and glucoamylase contained therein is 1:10, and the ratio of enzyme and starch is 1:100 (w / w), stirred at 55°C for 4h at a speed of 550rpm / min, suction filtered to obtain starch filter residue, dried at 85°C, and ground into powder.

[0036]In the second step, add 40 grams of microporous starch to 50 ml of distilled water, then add 0.4 g of anhydrous sodium carbonate and 2 g of sodium trimetaphosphate, bathe in water at 55 ° C for 10 h, filter the sample solution obtained by the reaction, and filter it at 85 °C, and ground into powder.

[0037] In the third step, add 2 g of the esterified microporous starch obtained by the reaction to 4 ml of an aqueous solution of thrombin with an activity of 20 U, place it at ...

Embodiment 3

[0039] A method for preparing self-assembled thrombin esterified microporous hemostatic starch, prepared by the following steps:

[0040] In the first step, 40g of cornstarch is added to 200ml of sodium acetate buffer solution with pH=4.6, the mixture ratio of α-amylase and glucoamylase contained therein is 1:4, and the ratio of enzyme and starch is 1:50 (w / w), stirred at 40°C at a speed of 250rpm / min for 10h, suction filtered to obtain starch filter residue, dried at 60°C, and ground into powder.

[0041] In the second step, add 20 grams of microporous starch to 50 ml of distilled water, then add 0.2 g of anhydrous sodium carbonate and 0.8 g of sodium trimetaphosphate, and put in a water bath at 50 ° C for 24 hours. Dry at 60°C and grind into powder.

[0042] In the third step, add 2 g of the esterified microporous starch obtained by the reaction to 4 ml of an aqueous solution of thrombin with an activity of 20 U, place it at 4°C for 1 hour, and filter it with suction to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com