Energy-saving and environmentally-friendly salt lake brine lithium extracting technology

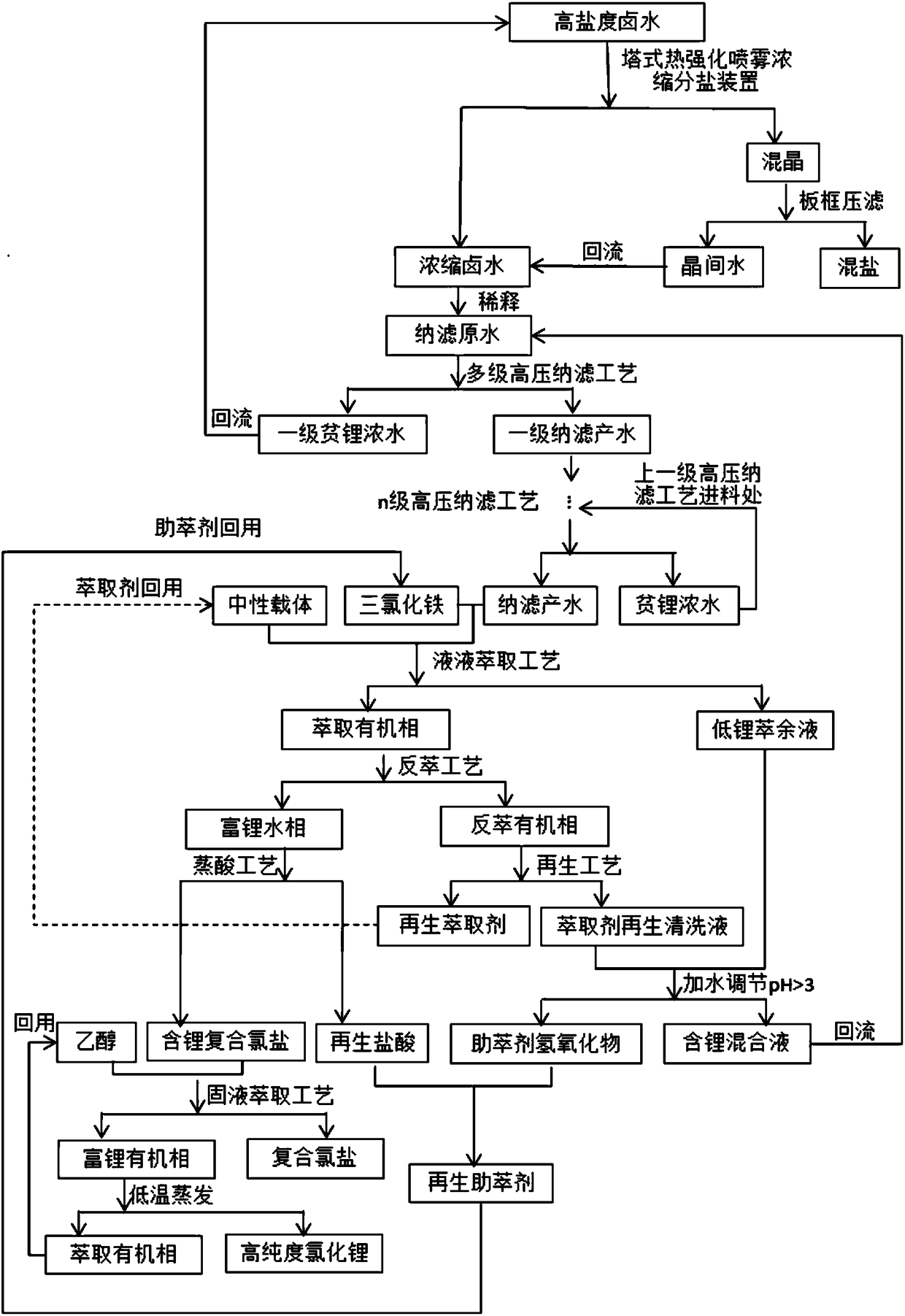

An energy-saving and environmental protection, salt lake brine technology, applied in the direction of process efficiency improvement, etc., can solve the problems of serious secondary pollution, low lithium recovery rate, high production cost, etc., achieve emission reduction production costs, reduce extraction stages, save land and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

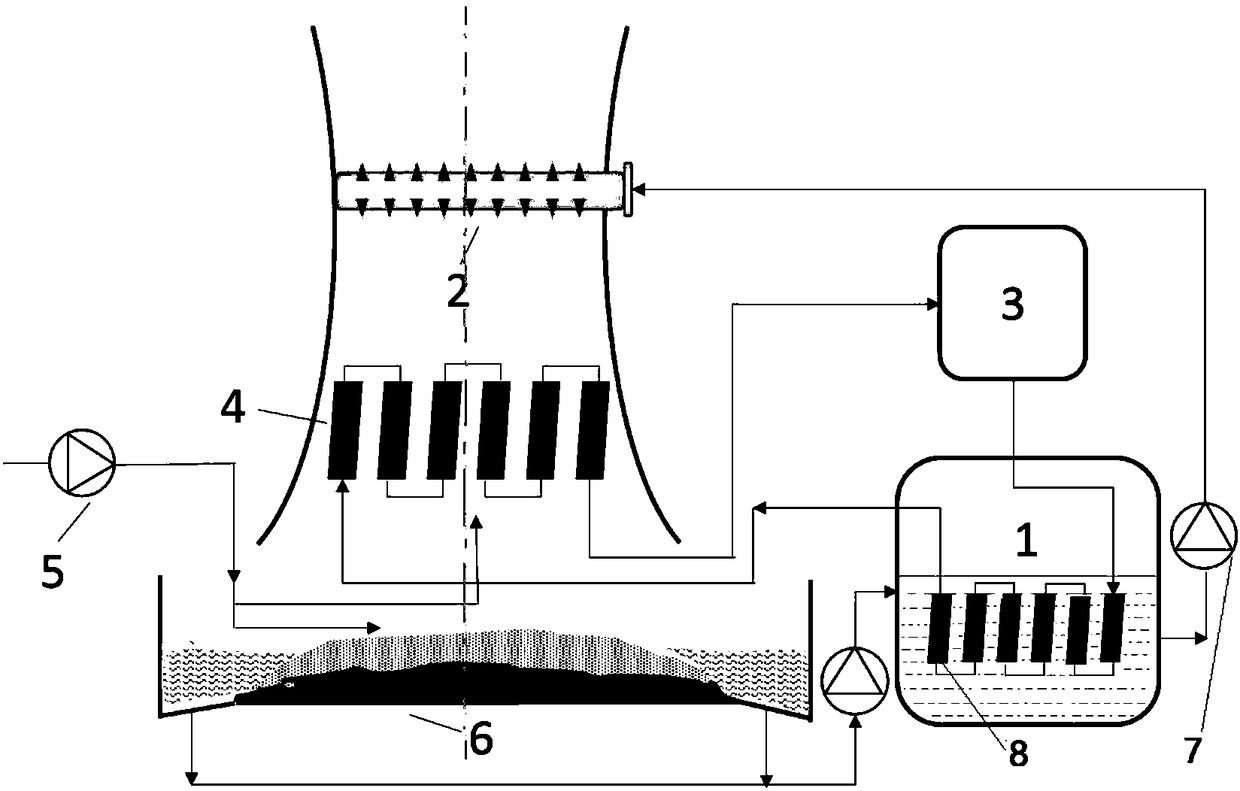

[0049] The mechanical concentration equipment is a tower-type heat-enhanced circulation spray concentration and salt separation device, and the high-pressure nanofiltration equipment includes membrane modules, high-pressure pumps and water production tanks. The composition of a lithium-containing brine: [Li + ]=1.69g / L, [Mg 2+ ]=114.73g / L, [Na + ]=25.20g / L, [K + ]=5.65g / L

[0050] 1) Tower-type heat-enhanced circulation spray concentration and salt separation device rich in lithium and reduce salt

[0051] The lithium-containing brine is cyclically concentrated using a tower-type thermally enhanced circulation spray concentration and salt separation device. The volume of the brine is concentrated by 5-6 times. During the concentration process, potassium, sodium, and magnesium salts are precipitated in the form of chloride solids.

[0052] After being circulated by a heat-intensified spray concentration device, water will be produced after concentration: [Li + ]=8.45g / L, [...

Embodiment 2

[0066] The mechanical concentration equipment is a tower-type heat-enhanced circulation spray concentration and salt separation device, and the high-pressure nanofiltration equipment includes membrane modules, high-pressure pumps and water production tanks. The composition of a lithium-containing brine: [Li + ]=0.19g / L, [Mg 2+ ]=23.75g / L, [Na + ]=81.85g / L, [K + ]=7.52g / L.

[0067] 1) Tower-type heat-intensified circulation spray concentration and salt separation device to reduce salt

[0068] The high-salinity brine is cyclically concentrated using a tower-type heat-intensified circulation spray concentration and salt separation device. The brine volume is concentrated by 9-10 times. During the concentration process, potassium, sodium, and magnesium salts are precipitated in the form of chloride solids.

[0069] After being circulated by a tower-type heat-intensified circulation spray concentration and salt separation device, water will be produced after concentration: [Li...

Embodiment 3

[0080] The mechanical concentration equipment is a tower-type heat-enhanced circulation spray concentration and salt separation device, and the high-pressure nanofiltration equipment includes membrane modules, high-pressure pumps and water production tanks. The composition of a lithium-containing brine: [Li + ]=0.83g / L, [Mg 2+ ]=76.88g / L, [Na + ]=23.50g / L, [K + ]=22.58g / L,

[0081] 1) Tower-type heat-intensified circulation spray concentration and salt separation device to reduce salt

[0082] The lithium-containing brine is cyclically concentrated using a tower-type heat-intensified circulation spray concentration and salt separation device. The volume of the brine is concentrated by 6-7 times. During the concentration process, potassium, sodium, and magnesium salts are precipitated in the form of chloride solids.

[0083] After being circulated by a tower-type heat-intensified circulation spray concentration and salt separation device, water will be produced after concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com