Coated electrode plate of electrostatic dust collector

An electrostatic precipitator and electrode plate technology, which is used in the field of key internal components and coated electrode plates, can solve the problems of unstable operation of the precipitator, low dust removal efficiency, easy corrosion by flue gas, etc., and achieves low friction coefficient and easy cleaning. Ash, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

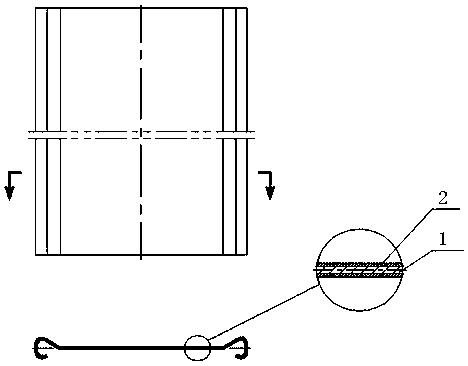

[0018] Such as figure 1 As shown, the coated electrode plate of the electrostatic precipitator is composed of the electrode plate 1 and the polymer coating 2. The pole plate 1 is formed by rolling or other methods, and the thickness of the pole plate is selected according to the design of the working condition. The processed electrode plate 1 should be removed from the surface rust, oil stains, impurities and other factors that affect the adhesion of the polymer coating 2.

[0019] A layer of polymer coating 2 is evenly covered on the surface of the flat and clean electrode plate 1 by spraying or other means. The polymer coating 2 has the characteristics of acid and alkali corrosion resistance, high temperature resistance, resistance to various organic solvents, and low friction coefficient. The polymer coating 2 can be made of polytetrafluoroethylene, and the coating thickness is selected according to the design of the working conditions.

[0020] The polymer coating 2 on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com