Aluminum-doped cobalt(II,III) oxide and preparation method and application thereof

A technology of cobalt tetroxide and aluminum doping, used in cobalt oxide/cobalt hydroxide, electrochemical generators, structural parts, etc., can solve problems such as uneven distribution of elements, large differences in sedimentation rates, and influence on the structural stability of lithium battery materials. , to achieve the effect of uniform distribution of each element, uniform distribution, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

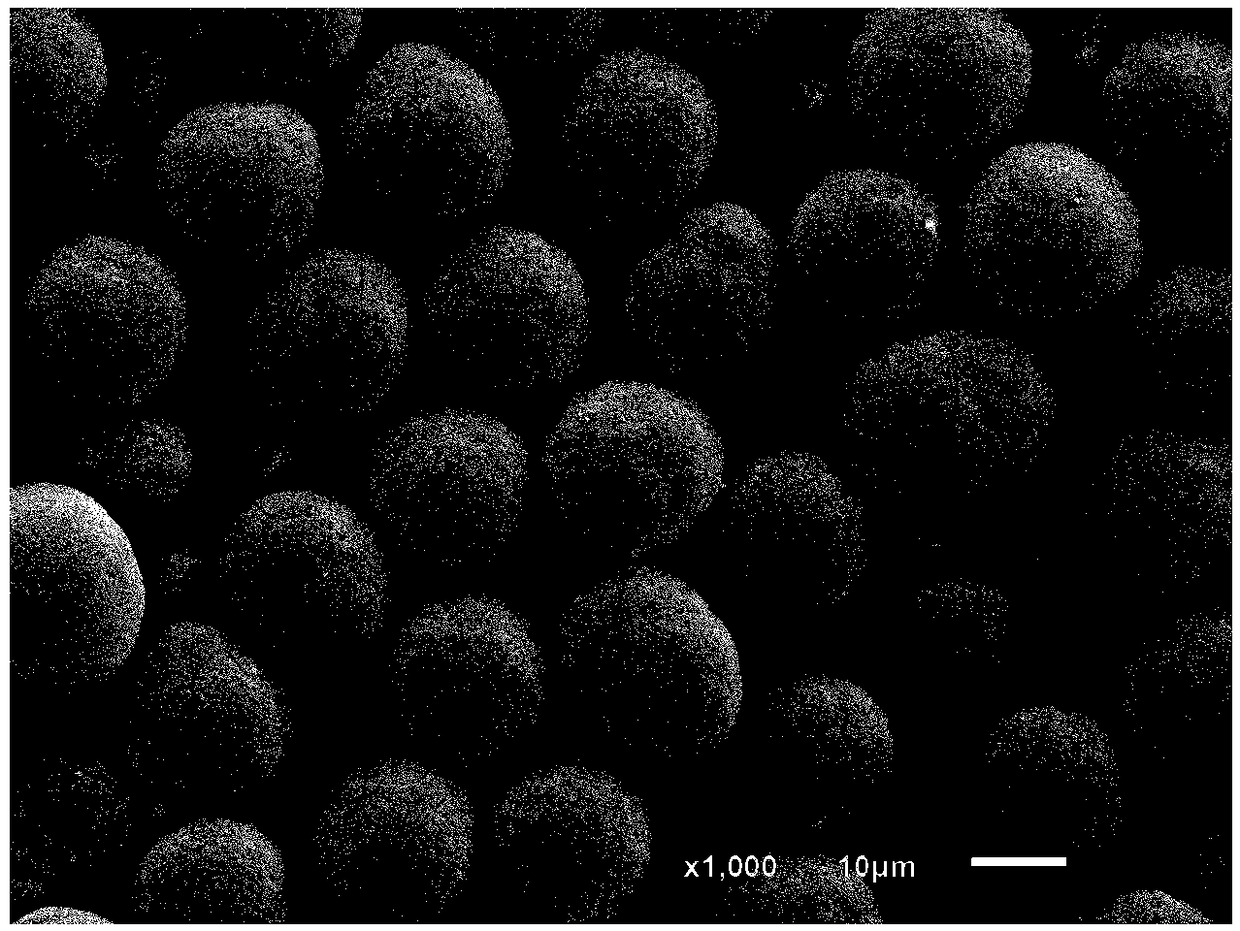

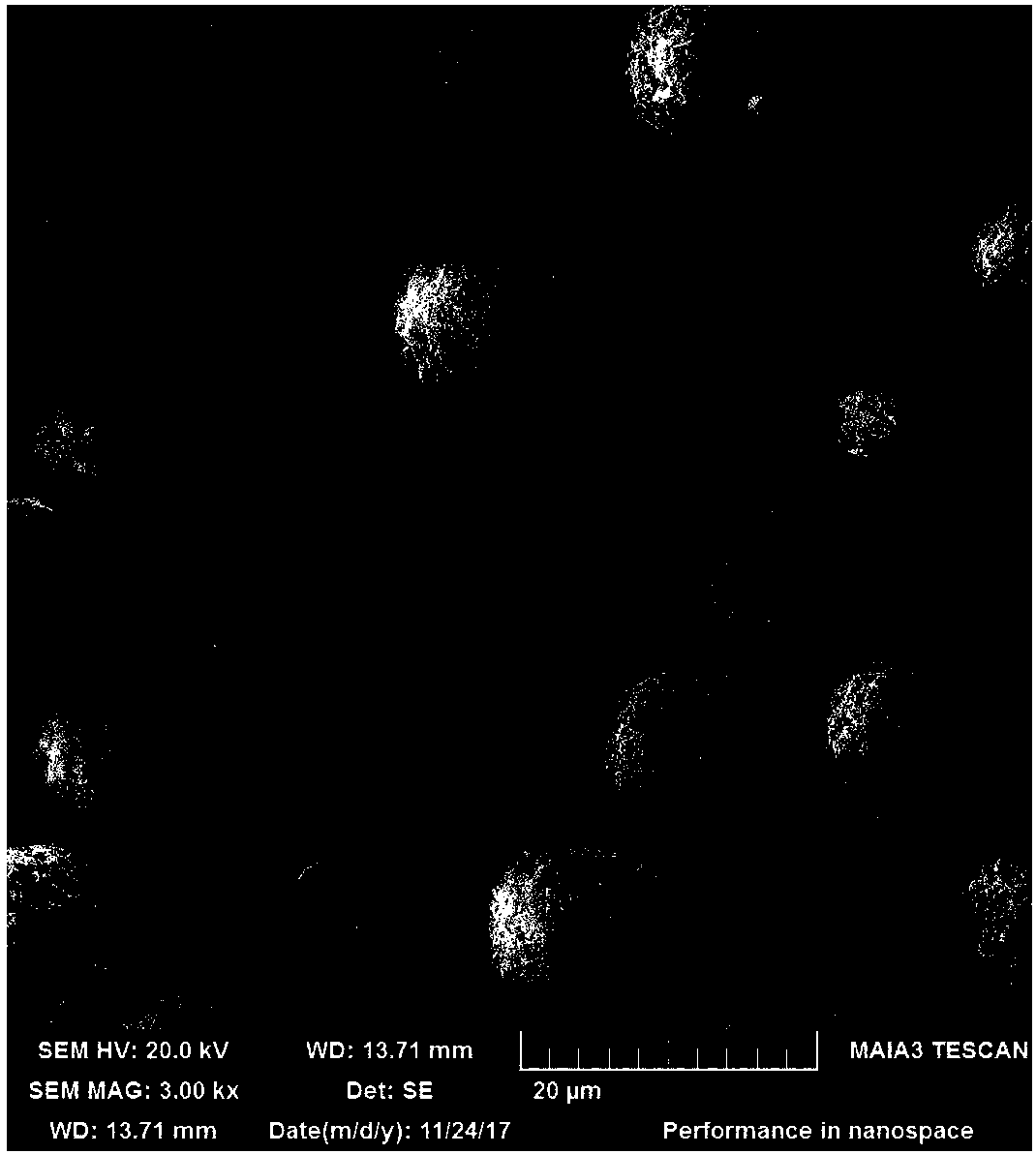

[0031] A preferred embodiment of the present invention provides a method for preparing aluminum-doped tricobalt tetroxide, comprising the following steps: (1) mixing an aluminum salt solution with a complexing agent to obtain a mixed solution; (2) mixing the cobalt salt solution, carbonate ion-containing The precipitant solution and the mixed solution prepared in step (1) are added into the reaction device in parallel flow, and co-precipitated to obtain aluminum-doped cobalt carbonate; (3) the aluminum-doped cobalt carbonate prepared in step (2) is Calcination can obtain aluminum doped tricobalt tetroxide.

[0032] The above-mentioned preparation method of aluminum-doped cobalt tetroxide, on the one hand, feeds the mixed solution of cobalt salt solution, precipitant solution and aluminum salt complexing agent in parallel flow, which overcomes the process of preparing aluminum-doped cobalt tetroxide by liquid phase co-precipitation method The problem of the large difference in ...

Embodiment 1

[0049] (1) The concentration is 0.015mol / L aluminum salt solution is mixed with citric acid solution to obtain a mixed solution, wherein the molar ratio of aluminum ion and complexing agent in the aluminum salt solution is 1: 0.5, and ammonium bicarbonate is used to adjust the pH value of the mixed solution is 2.5;

[0050] (2) The cobalt ion concentration is the cobalt salt solution of 0.4mol / L, the 2mol / L ammonium bicarbonate solution and the three kinds of solutions of the mixed solution in the step (1) and adopts the mode of concurrent flow to add the reactor with deionized water , the feed rate of the cobalt salt solution is 50ml / min, the feed rate of the mixed solution is 10ml / min, and the reaction conditions in the reactor are: pH value 7.1, temperature 35°C, reaction time 72h, to obtain aluminum-doped cobalt carbonate ;

[0051] (3) Wash the aluminum-doped cobalt carbonate in step (2) until the content of chloride ions is less than 100ppm, place it in a pusher kiln fo...

Embodiment 2

[0056] (1) the concentration is 0.075mol / L aluminum salt solution and citric acid solution are mixed to obtain mixed solution, the mol ratio of aluminum ion and complexing agent in aluminum salt solution is 1: 3, adopts the pH value of ammonium bicarbonate to adjust mixed solution 3.2;

[0057] (2) Three kinds of solutions of the cobalt salt solution, the 2mol / L ammonium bicarbonate solution and the mixed solution in the step (1) that the cobalt ion concentration is 1.8mol / L are added into the reaction kettle with deionized water in a parallel flow mode , the feed rate of the cobalt salt solution is 10ml / min, the feed rate of the mixed solution is 2ml / min, and the reaction conditions in the reactor are: pH value 7.1, temperature 40°C, reaction time 96h, to obtain aluminum-doped cobalt carbonate ;

[0058] (3) Wash the aluminum-doped cobalt carbonate in step (2) until the chloride ion content is less than 100ppm, place it in a pusher kiln for calcination, the calcination tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com