Carbon nanotube/copper high-current-carrying composite lead and preparation method thereof

A technology of carbon nanotubes and composite wires, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as difficulties in electroplating solutions and difficult carbon nanotube films to form a uniform seed layer. Achieve the effect of uniform composite phase and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

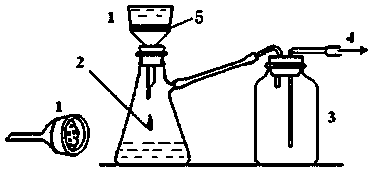

[0027] A specific embodiment of a method for preparing a carbon nanotube / copper high current-carrying composite wire is carried out according to the following steps:

[0028] In the first step, the carbon nanotube film produced by Suzhou Jiedi Nano Technology Co., Ltd. was cut into an area the size of a 2-inch flat-bottomed funnel, and the film was soaked in analytically pure acetone and heated at 50°C for 30 minutes before taking it out. Then soak it in analytically pure ethanol and heat it at 80°C for 30 minutes, take it out, and dry it in an oven at 75°C. The dried films were heated to 75 °C in 0.2 M dilute hydrochloric acid and kept for 60 min. Repeat the dilute hydrochloric acid process 3 times, take it out and put it in a vacuum oven to dry at 80°C for later use.

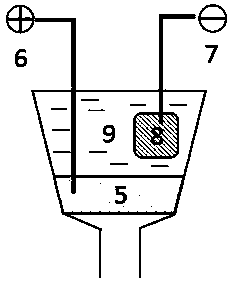

[0029] In the second step, the above-mentioned treated carbon nanotube film is placed in a 2-inch flat-bottomed funnel, and a small amount of ethanol is used to infiltrate the carbon nanotube film to keep the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com