CdS quantum dot-complex composite material preparation method and application

A technology of composite materials and complexes, which is applied in the fields of electrochemical variables of materials, electrolytic organic material coating, electrolytic inorganic material coating, etc., can solve the problems of harsh preparation conditions, complex reaction steps, high reagent cost, and achieve high chemical stability, Short time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 A preparation method of CdS quantum dot-complex composite material

[0042] (1) Preparation of adamantane-based ligand ADM-BP

[0043] Blend 1.8771g amantadine hydrochloride, 2g potassium carbonate and 60mL acetonitrile, add 1.3203g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to room temperature , filtered, washed with acetonitrile and water successively, and dried at 60°C; the obtained solid was dissolved in 20 mL of dichloromethane, and then 15 mL of water was added, shaken sufficiently, allowed to stand, and separated; the obtained organic layer was dried by adding sodium sulfate, Distillation, remove solvent, obtain adamantane amino ligand ADM-BP powder, productive rate is 70%;

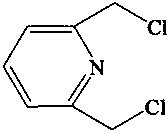

[0044] Described amantadine hydrochloride, structural formula is as follows:

[0045]

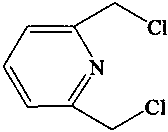

[0046] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0047]

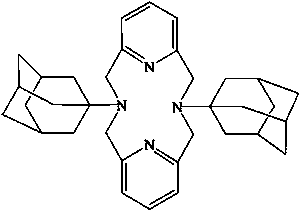

[0048] The structural formula of the adamanty...

Embodiment 2

[0060] Embodiment 2 A kind of preparation method of CdS quantum dot-complex composite material

[0061] (1) Preparation of adamantane-based ligand ADM-BP

[0062] Blend 2.3464g amantadine hydrochloride, 2.5g potassium carbonate and 70mL acetonitrile, add 1.7604g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to Filter at room temperature, wash with acetonitrile and water successively, and dry at 60°C; dissolve the obtained solid in 25 mL of dichloromethane, add 15 mL of water, shake fully, stand still, and separate; add sodium sulfate to the obtained organic layer to dry , distillation, solvent removal, to obtain the adamantane amino ligand ADM-BP powder, the yield is 75%;

[0063] Described amantadine hydrochloride, structural formula is as follows:

[0064]

[0065] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0066]

[0067] The structural formula of the adamantyl amino ligand ADM-BP is as...

Embodiment 3

[0079] Embodiment 3 A kind of preparation method of CdS quantum dot-complex composite material

[0080] (1) Preparation of adamantane-based ligand ADM-BP

[0081] Blend 2.8157g amantadine hydrochloride, 3g potassium carbonate and 80mL acetonitrile, add 2.2005g 2,6-bis(chloromethyl)pyridine, stir vigorously; heat to 80°C, react for 24 hours, then cool to Filter at room temperature, wash with acetonitrile and water successively, and dry at 60°C; dissolve the obtained solid in 30 mL of dichloromethane, add 15 mL of water, shake fully, stand still, and separate; add sodium sulfate to the obtained organic layer to dry , distillation, solvent removal, to obtain the adamantyl amino ligand ADM-BP powder, the yield is 72%;

[0082] Described amantadine hydrochloride, structural formula is as follows:

[0083]

[0084] Described 2,6-bis(chloromethyl)pyridine, structural formula is as follows:

[0085]

[0086] The structural formula of the adamantyl amino ligand ADM-BP is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com