Plasma etching cleaning liquid, method for preparing same and application of plasma etching cleaning liquid

A technology of cleaning liquid and plasma, which is applied in the field of chemical reagents, can solve the problems that affect the cleaning effect of semiconductor devices, the circuit conduction effect, the large increase of particles, and the semiconductor devices that are easy to corrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

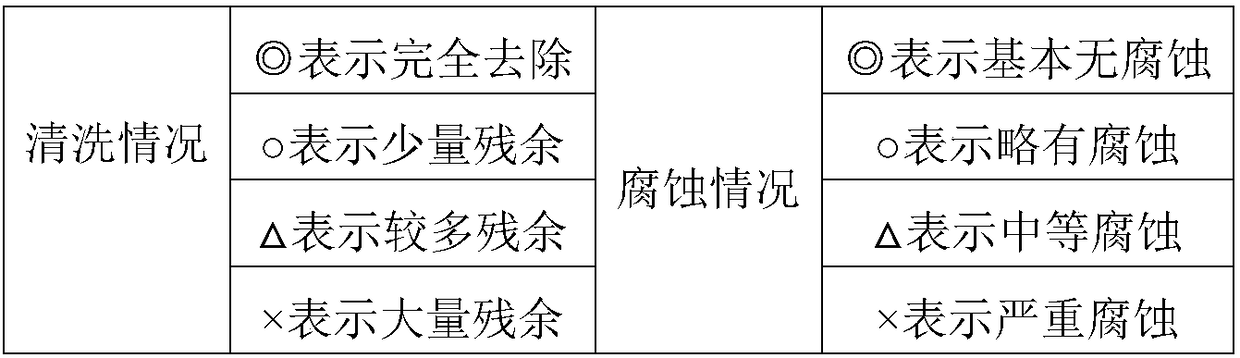

Image

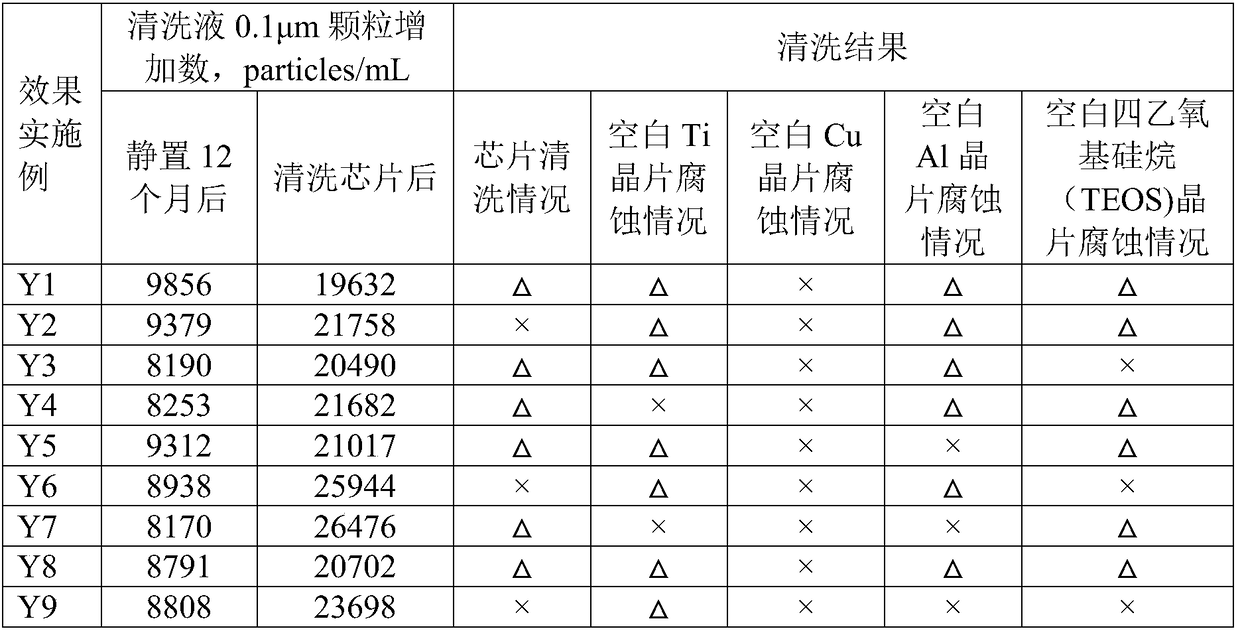

Examples

preparation Embodiment 1-9

[0061] Prepared plasma etching cleaning solution 1-9 according to the preparation method of above-mentioned plasma etching cleaning solution, wherein the composition and content of each cleaning solution are shown in Table 1; wherein cleaning solution 1-9 does not contain dispersant and Cyclodextrin modified alkylene glycol alkyl ether compound.

[0062] Table 1

[0063]

preparation Embodiment 11-19

[0091] The preparation examples 11-19 of the present invention are based on the cleaning liquid prepared in the aforementioned preparation examples 1-9, respectively added dispersant, the type and amount of the added dispersant and the amount of water are shown in Table 4, and the rest The components and contents remained unchanged, thus correspondingly obtained plasma etching cleaning solutions 11-19.

[0092] Table 4

[0093]

preparation Embodiment 21-29

[0100] Preparation Examples 21-29 of the present invention are based on the aforementioned cleaning solutions 11-19, respectively adding cyclodextrin-modified alkylene glycol alkyl ether compounds, and the added cyclodextrin-modified alkylene glycol alkyl The dosage of the base ether compound and the dosage of water are shown in Table 6, and the remaining components and contents remain unchanged, thus the plasma etching cleaning solutions 21-29 are correspondingly obtained.

[0101] Table 6

[0102]

[0103] Note 1: The mass content of p-toluenesulfonic acid mentioned in Table 6 refers to the percentage of the mass of p-toluenesulfonic acid to the total mass of substance A and cyclodextrin.

[0104] Note 2: In Examples 21-29, the reaction temperature and time of each step in the preparation of cyclodextrin-modified alkylene glycol alkyl ether compounds are shown in Table 7.

[0105] Table 7

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com