Preparation method of fluorescent carbon quantum dot

A carbon quantum dot and fluorescence technology, which is applied in the field of preparation of fluorescent carbon quantum dots, can solve the problems of complex preparation process and narrow tunable range of emission wavelength of fluorescent carbon quantum dots, and achieves simple synthesis process, small change in luminous intensity, and high productivity. high efficiency and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix 25 mL of chromatographic grade absolute ethanol with a purity of 99.8% and 25 mL of ultrapure water in a 100 mL beaker, add 2 g of sorbose, heat and stir to dissolve the sorbose. Then the mouth of the beaker was sealed and further ultrasonically mixed for 20 min.

[0029] (2) Place the ultrasonically mixed solution in a 100mL brown polytetrafluoroethylene liner, seal it in a corresponding high-pressure reactor, and heat it in a high-temperature drying oven for hydrothermal reaction. The reaction temperature is 180°C, and the time is 4h.

[0030] (3) Filter the reaction solution after pyrolysis and carbonization through a 0.22um polytetrafluoroethylene filter, then place it in the dialysis bag of WM1000, and dialyze it in ultrapure water for 2 days to obtain an aqueous solution of carbon quantum dots.

[0031] (4) Vacuum drying the aqueous solution of carbon quantum dots to obtain target carbon quantum dots.

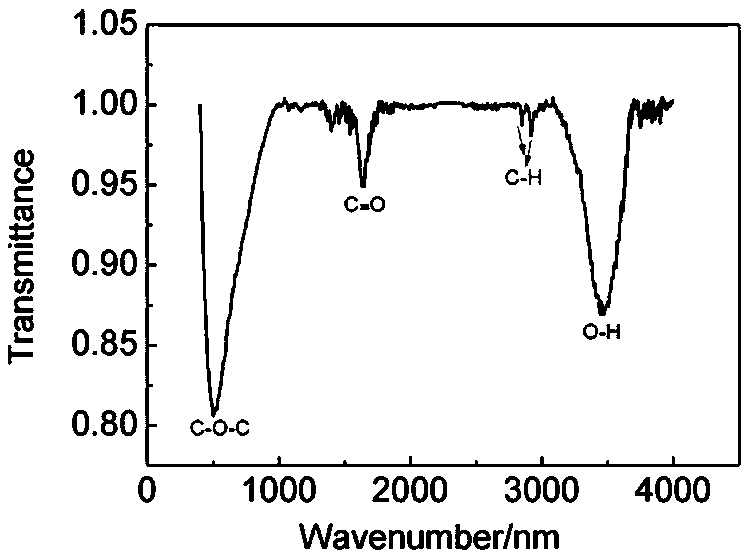

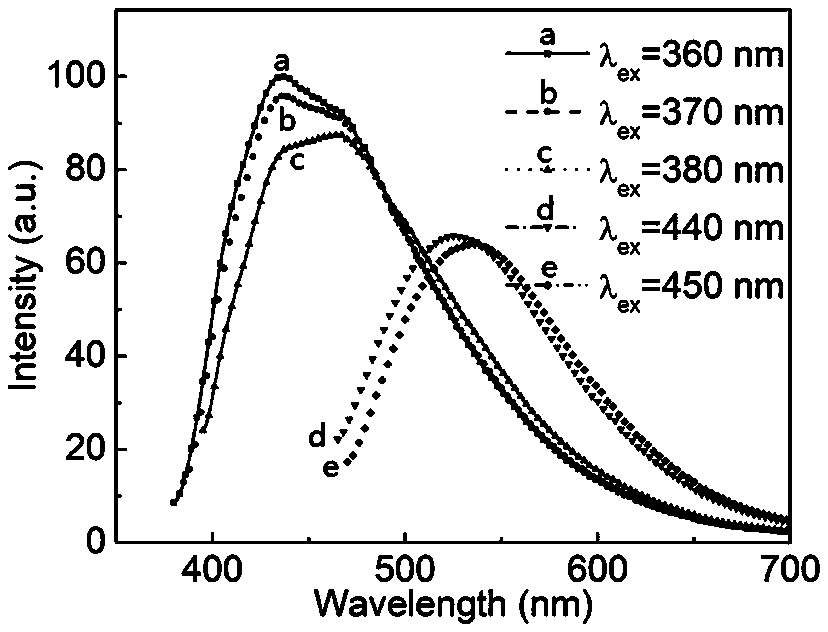

[0032] Characterization of the above-mentioned carb...

Embodiment 2

[0034] (1) Mix 17 mL of chromatographic grade absolute ethanol with a purity of 99.8% and 33 mL of ultrapure water in a 100 mL beaker, add 2 g of sorbose, heat and stir to dissolve the sorbose. Then the mouth of the beaker was sealed and further ultrasonically mixed for 20 min.

[0035] (2) Place the ultrasonically mixed solution in a 100mL brown polytetrafluoroethylene liner, seal it in a corresponding high-pressure reactor, and heat it in a high-temperature drying oven for hydrothermal reaction. The reaction temperature is 180°C, and the time is 4h.

[0036] (3) Filter the reaction solution after pyrolysis and carbonization through a 0.22um polytetrafluoroethylene filter, then place it in the dialysis bag of WM1000, and dialyze it in ultrapure water for 2 days to obtain an aqueous solution of carbon quantum dots.

[0037] (4) Vacuum drying the aqueous solution of carbon quantum dots to obtain target carbon quantum dots.

[0038] The related properties of the obtained carbo...

Embodiment 3

[0040] (1) Mix 12.5 mL of chromatographic grade absolute ethanol with a purity of 99.8% and 37.5 mL of ultrapure water into a 100 mL beaker, add 2 g of sorbose, heat and stir to dissolve the sorbose. Then the mouth of the beaker was sealed and further ultrasonically mixed for 20 min.

[0041] (2) Place the ultrasonically mixed solution in a 100mL brown polytetrafluoroethylene liner, seal it in a corresponding high-pressure reactor, and heat it in a high-temperature drying oven for hydrothermal reaction. The reaction temperature is 180°C, and the time is 4h.

[0042] (3) Filter the reaction solution after pyrolysis and carbonization through a 0.22um polytetrafluoroethylene filter, then place it in the dialysis bag of WM1000, and dialyze it in ultrapure water for 2 days to obtain an aqueous solution of carbon quantum dots.

[0043] (4) Vacuum drying the aqueous solution of carbon quantum dots to obtain target carbon quantum dots.

[0044] The related properties of the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com