A core/shell structured ti 3 c 2 Oxene/cu powder and preparation method thereof

A shell structure, powder technology, applied in metal processing equipment, liquid chemical plating, transportation and packaging, etc., to achieve the effect of uniform coating, improved wettability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

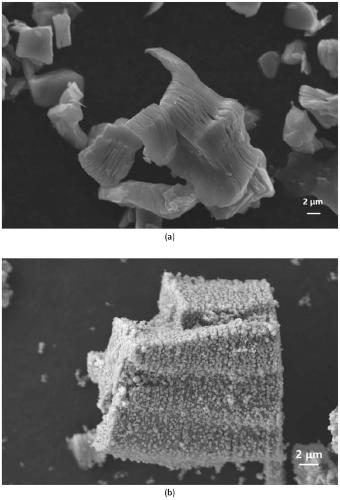

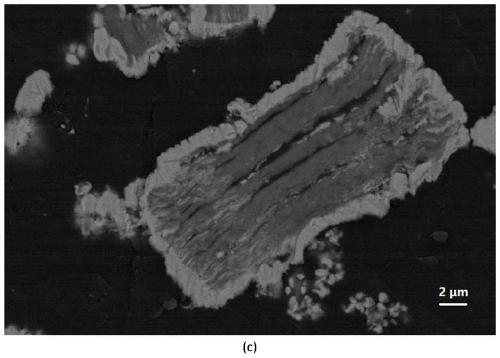

Image

Examples

Embodiment approach 1

[0023] 1. The composition of the electroless plating solution is: 10g / L copper sulfate pentahydrate, 10g / L disodium ethylenediamine tetraacetate, 20mg / L 2,2'-bipyridyl, adjust the pH of the plating solution to 9-10 with NaOH solution . The reducing agent is: 10ml / L 80% hydrazine hydrate.

[0024] 2. Electroless plating:

[0025] (1) Add 0.25g Ti 3 C 2 Add it to 400ml plating solution, control the temperature of the mixed solution at 45-50°C, and use magnetic stirring for continuous stirring;

[0026] (2) Use a separating funnel to add 100ml of hydrazine hydrate dropwise to the mixed solution, control the titration rate, and finish the titration in 15 minutes, and add NaOH solution in time during the process to ensure that the pH value is maintained at the specified value;

[0027] (3) After the titration, the mixed solution is centrifugally cleaned with deionized water until the pH value is about 7, and finally the sample is washed with absolute ethanol, and the red powder...

Embodiment approach 2

[0030] 1. The composition of the electroless plating solution is: 20g / L copper sulfate pentahydrate, 30g / L disodium ethylenediamine tetraacetate, 10mg / L 2,2'-bipyridyl, adjust the pH of the plating solution to 10-11 with NaOH solution . The reducing agent is: 20ml / L 80% hydrazine hydrate.

[0031] 2. Electroless plating:

[0032] (1) Add 0.25g Ti 3 C 2 Add it to 400ml plating solution, control the temperature of the mixed solution at 60-65°C, and use magnetic stirring for continuous stirring;

[0033] (2) Use a separating funnel to add 100ml of hydrazine hydrate dropwise to the mixed solution, control the titration rate, and finish the titration in 30 minutes, and add NaOH solution in time during the process to ensure that the pH value is maintained at the specified value;

[0034] (3) After the titration, the mixed solution is centrifugally cleaned with deionized water until the pH value is about 7, and finally the sample is washed with absolute ethanol, and the red powde...

Embodiment approach 3

[0037] 1. The composition of the electroless plating solution is: 20g / L copper sulfate pentahydrate, 20g / L disodium ethylenediamine tetraacetate, 30mg / L 2,2'-bipyridyl, adjust the pH of the plating solution to 11-12 with NaOH solution . The reducing agent is: 30ml / L 80% hydrazine hydrate.

[0038] 2. Electroless plating:

[0039] (1) Add 0.25g Ti 3 C 2 Add it to 400ml plating solution, control the temperature of the mixed solution at 75-80°C, and use magnetic stirring for continuous stirring;

[0040] (2) Use a separating funnel to add 100ml of hydrazine hydrate dropwise to the mixed solution, control the titration rate, and finish the titration in 60 minutes, and add NaOH solution in time during the process to ensure that the pH value is maintained at the specified value;

[0041] (3) After the titration, the mixed solution is centrifugally cleaned with deionized water until the pH value is about 7, and finally the sample is washed with absolute ethanol, and the red powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com