Inductance element and manufacturing method

A technology of inductive components and electrodes, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, transformer/inductance parts, etc., can solve the problem that it is difficult to ensure the position of the coil design, the product space utilization rate is low, and the coil is easy to shift and other issues to achieve good consistency, reduce the risk of open circuits, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

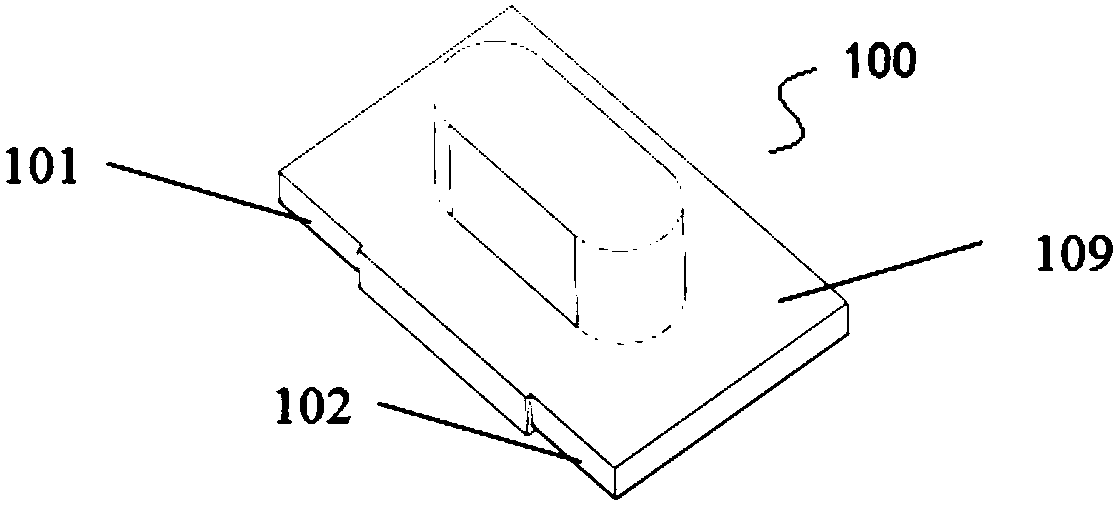

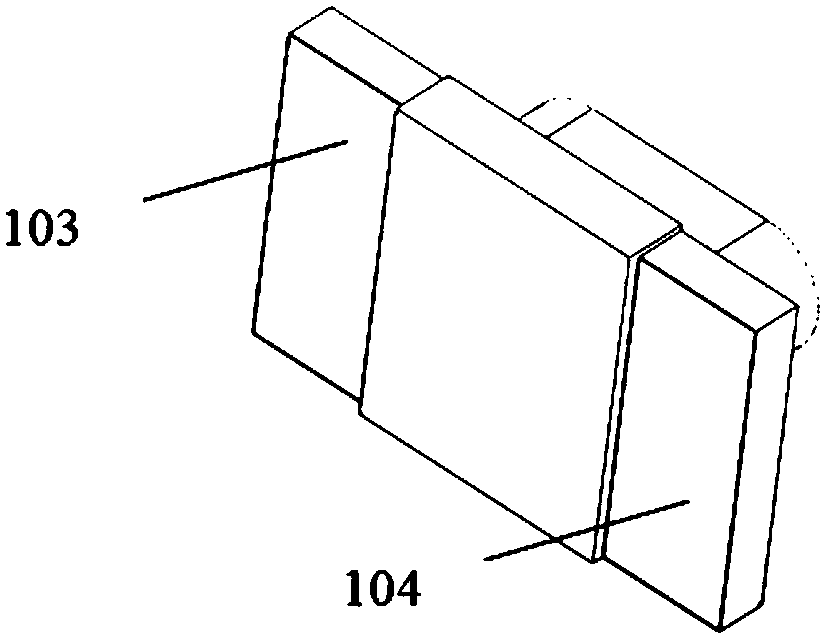

[0061] Such as figure 1 As shown, the T-shaped magnetic core of FeSiCr material can be manufactured by one-time pressing and molding process, preferably, the magnetic permeability is 40-150, and the saturation magnetic flux is 10000-15000 mT. Preferably, as figure 2 As shown, the bottom of the magnetic core is provided with two parallel electrode slots 103, 104, and two wire hanging slots or electrode slots 101, 102 are provided on the side. The metallization layer is preferably formed in the electrode groove by a sputtering process.

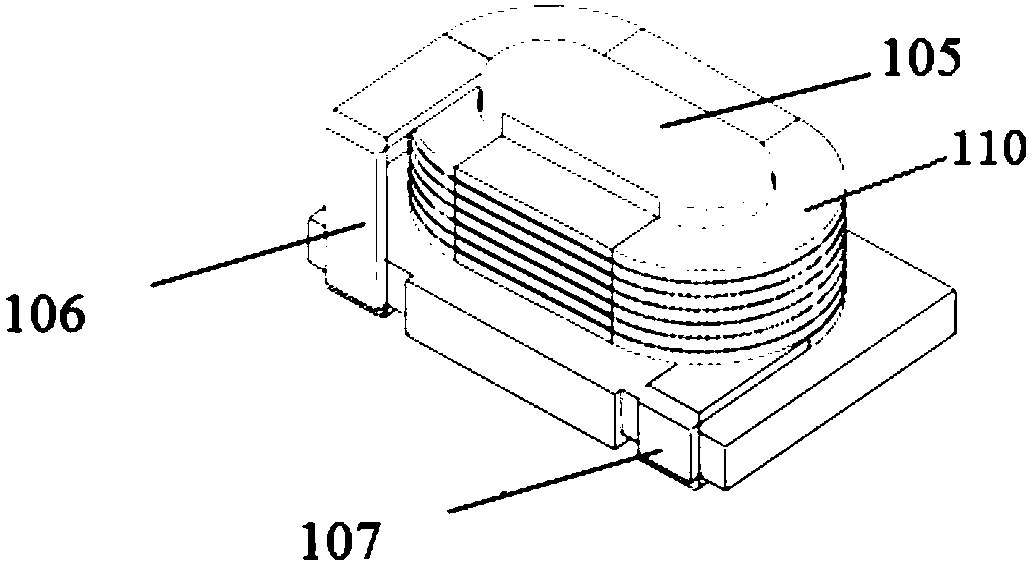

[0062] A winding machine may be used to wind the wires on the central column 105 of the T-shaped magnetic core. Such as image 3 As shown, preferably, after the coil winding product is completed, the lead-out ends 106, 107 of the coil are received into the electrode slots 103, 104.

[0063] Figure 4 It is a schematic diagram of the finished product formed after magnetic glue potting. The magnetic core wrapped with the wire is covered wi...

example 2

[0066] Such as Figure 6 As shown, the metal soft magnetic alloy I-shaped prefabricated magnetic core can also be made by powder molding process. Preferably, the magnetic permeability is 40-90, the saturation magnetic flux is 10000-15000mT, and the material of the I-shaped magnetic core is preferably carbonyl iron powder .

[0067] The base of the prefabricated I-shaped magnetic core can be rectangular, such as Figure 7 As shown, a flat coil can be wound on the center column 203 of the prefabricated magnetic core by a winding machine, which has two lead-out ends 201, 202, and the two lead-out ends 201, 202 are respectively bent and closely attached to the I-shaped magnetic core. The lower blade 204 sides of the core. Then, by laser welding, the metallized layers of the two lead-out ends 201, 202 are welded on the side to form a Figure 7 structure shown.

[0068] Figure 8 It is a schematic diagram of wrapping the flat coil with the magnetic glue layer 205 . Figure 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com