Preparation method of core-shell GaN nanowire array

A nanowire array and core-shell technology, which is applied in the field of electricity, can solve problems such as the difficulty in preparing high-quality, orderly arranged core-shell GaN nanowire arrays, and achieve significant technological progress, simple process, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Fabrication of a core-shell GaN nanowire array with a quantum well structure with a nanowire diameter less than 200 nm and a height of 4 μm

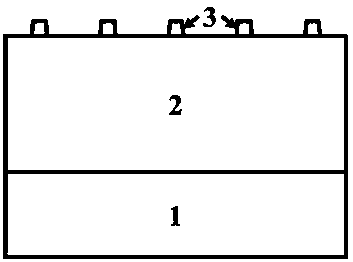

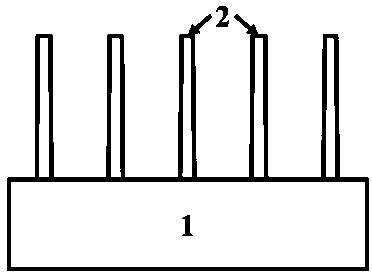

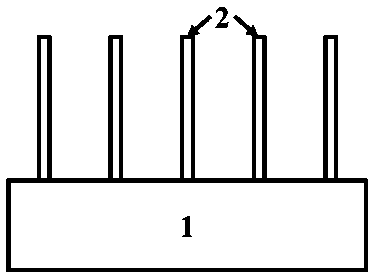

[0030] Figure 1~4 It is a flow chart for preparing a core-shell GaN nanowire array, and a method for preparing a core-shell GaN nanowire array of the present invention includes the following steps:

[0031] 1) if figure 1 As shown, the metal organic vapor phase chemical deposition (MOCVD) method is used to epitaxially buffer layer and n-GaN 2 on the Si substrate 1 in sequence, with a total thickness of about 6 μm;

[0032] 2) 1 μm thick SiO was grown on the epitaxial layer by CVD method 2 Mask layer 3, preparing a circular mask pattern with a diameter of 5 μm by photolithography and ICP etching process;

[0033] 3) Use buffered oxide etchant BOE to etch SiO 2 The mask layer 3 is etched for 5min and 50s at a temperature of 22°C to prepare a mask with a size of about 500 nm;

[0034] 4) The GaN-based epitaxial layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com