As-cast high-strength nodular cast iron for crankshaft and preparation method of as-cast high-strength nodular cast iron

A ductile iron, high-strength technology, applied in the field of ductile iron materials, can solve the problems of unsuitability for ductile iron, production, insufficient tensile strength and elongation of crankshafts, etc., to shorten the production cycle, save heat treatment costs, and achieve excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

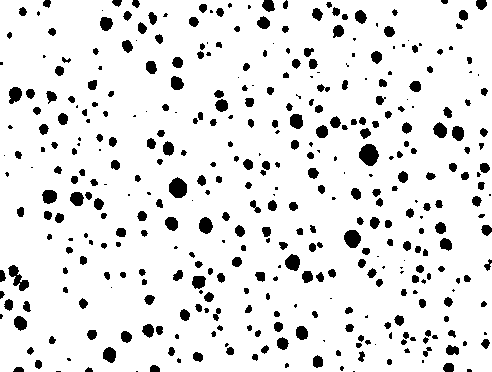

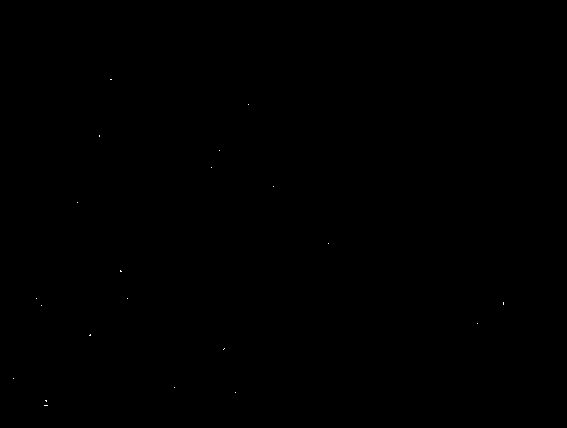

Image

Examples

preparation example Construction

[0039]The preparation method of the as-cast high-strength nodular cast iron for the crankshaft comprises the following steps:

[0040] Ⅰ. Raw material preparation and proportioning: The raw materials and proportioning are as follows: high-purity pig iron 40-50%, scrap steel 30-35%, nodular iron return charge 15-30%, copper 0.4-0.9%, manganese ferroalloy 0.3-1.0% , antimony alloy 0.002-0.1%;

[0041] II. Smelting: Put the high-purity pig iron described in step I into an intermediate-frequency induction furnace for smelting, and then add the scrap steel and recycled materials described in step I in sequence after seeing the molten iron, and add ferromanganese alloy and antimony to the molten iron after all the furnace materials are melted into liquid Alloy and copper, when the temperature of the molten iron reaches ≥1520°C, take a sample to detect the chemical composition in the furnace, and make fine adjustments to the chemical composition of the elements in the molten iron acc...

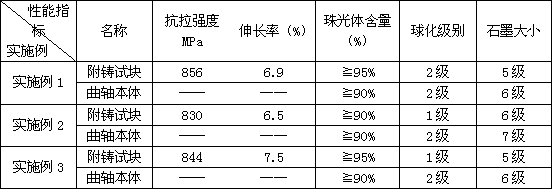

Embodiment 1

[0053] An as-cast high-strength nodular cast iron for crankshafts, the grade is QT800-6, composed of the following elements by weight percentage: CE: 4.2, C: 3.5%, Si: 2.2%, Mn: 0.5%, P: 0.015% , S: 0.015%, Cu: 0.8%, Sb: 0.002%, the balance is Fe and unavoidable trace elements.

[0054] The preparation method of the as-cast high-strength nodular cast iron QT800-6 for the crankshaft comprises the following steps:

[0055] Ⅰ. Raw material preparation and proportioning: The raw materials used and proportioning by weight are as follows: High-purity pig iron accounts for 40%, steel scrap accounts for 30%, nodular iron recycled materials accounts for 30%, copper 0.8%, ferromanganese alloy 1.0%, antimony Alloy 0.002%;

[0056] II. Smelting: Put the high-purity pig iron described in step I into an intermediate frequency induction furnace for smelting, add scrap steel and nodular iron as described in step I in sequence after seeing the molten iron, and add ferromanganese alloy to the ...

Embodiment 2

[0069] An as-cast high-strength nodular cast iron QT800-6 for crankshafts, composed of the following elements by weight percentage: CE: 4.5, C: 3.9%, Si: 1.8%, Mn: 0.25%, P: 0.03%, S: 0.005%, Cu: 0.4%, Sb: 0.01%, the balance is Fe and unavoidable trace elements.

[0070] Ⅰ. Raw materials and proportioning: The raw materials used and proportioning by weight are as follows: high-purity pig iron accounts for 50%, steel scrap accounts for 35%, ductile iron recycle materials account for 15%, copper 0.4%, ferromanganese alloy 0.3%, antimony alloy 0.1%;

[0071] II. Smelting: Put the high-purity pig iron described in step I into an intermediate frequency induction furnace for smelting, add scrap steel and nodular iron as described in step I in sequence after seeing the molten iron, and add ferromanganese alloy to the molten iron after all the furnace materials are melted into a liquid state , antimony alloy and copper, when the temperature of the molten iron reaches ≥1520°C, take a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com