A kind of microporous carboxylated silica gel, preparation method and application thereof

A carboxylation, silica gel technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., can solve the problems of difficulty in repeated use, poor adsorption capacity, etc., and achieve the effect of simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

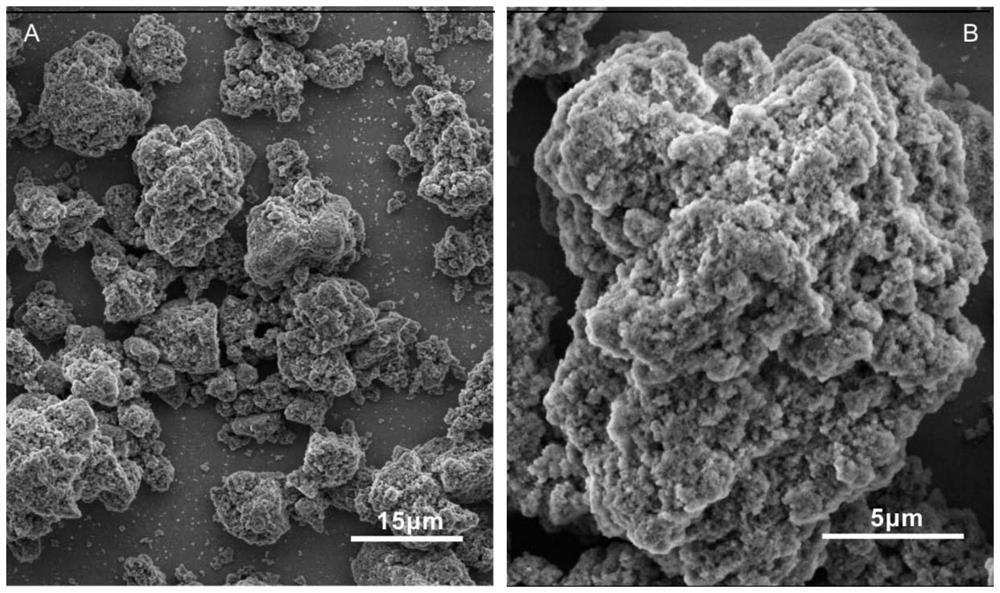

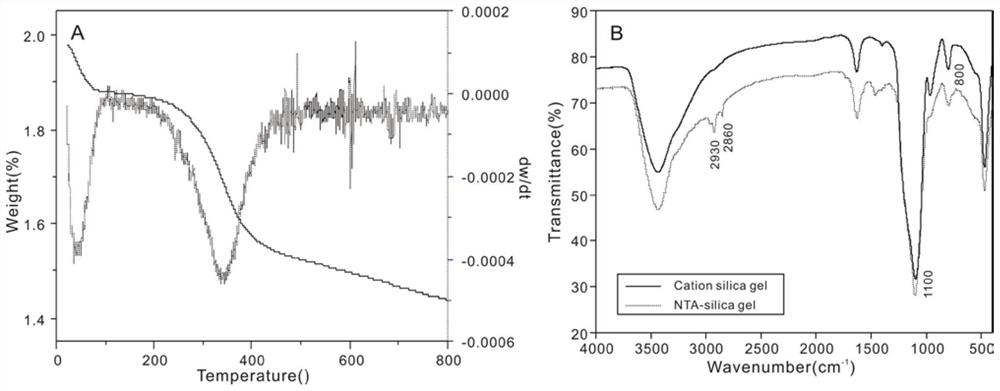

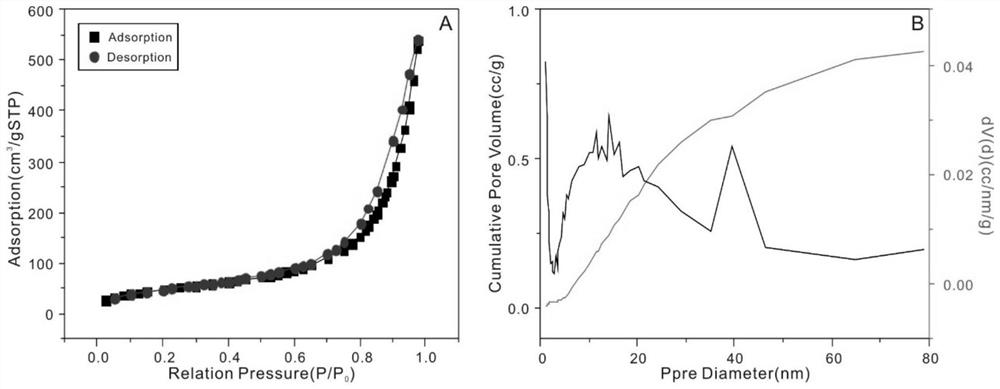

Image

Examples

Embodiment 1

[0037] A kind of preparation method of microporous carboxylated silica gel, reacts according to following formula:

[0038]

[0039] Specifically include the following steps:

[0040] 1) Weigh 10g of inorganic silica gel mSiO 2 ·nH 2 O and 3mL of 3-aminopropyltriethoxysilane were dissolved in 100mL of toluene solvent, and stirred and refluxed in a reflux device for 16h under the condition of an oil bath at 110°C;

[0041] 2) After the reaction in step 1) is completed, the reaction product is cooled and filtered, and firstly adopts 150 mL of mass concentration to be 50% toluene solution for centrifugal cleaning, and then adopts 150 mL of mass concentration for 50% acetone solution for centrifugal cleaning, and then at 105° C. Dry for 4 hours;

[0042] 3) Weigh 3.35g of nitrilotriacetic acid and 4.05g of the reaction product obtained in step 2), dissolve in 400mL of pyridine solvent, and stir under reflux for 3h in an oil bath at 90°C;

[0043] 4) After the reaction in st...

Embodiment 2

[0057] A preparation method of microporous carboxylated silica gel, specifically comprising the following steps:

[0058] 1) Weigh 5g of inorganic silica gel mSiO with different specific surface areas 2 ·nH 2 O and 1.5mL of silane coupling agent 3-aminopropyltriethoxysilane containing different chemical groups were dissolved in 80mL of toluene solvent, and stirred and refluxed in a reflux device for 10h under the condition of an oil bath at 100°C;

[0059] 2) After the reaction in step 1) is finished, the reaction product is cooled and filtered, and firstly adopt 120mL mass concentration of 2% toluene solution for centrifugal cleaning, then adopt 120mL mass concentration of 2% acetone solution for centrifugal cleaning, and then place the reaction product at 100°C Dry for 3 hours;

[0060] 3) Weigh 2.5 g of nitrilotriacetic acid and 3.5 g of the reaction product obtained in step 2), dissolve it in 250 mL of pyridine solvent, and stir under reflux for 1 h under the condition o...

Embodiment 3

[0066] A preparation method of microporous carboxylated silica gel, specifically comprising the following steps:

[0067] 1) Weigh 15g of inorganic silica gel mSiO with different specific surface areas 2 ·nH 2 O and 5mL of silane coupling agent 3-aminopropyltriethoxysilane containing different chemical groups were dissolved in 120mL of toluene solvent, and stirred and refluxed in a reflux device for 20h under the condition of an oil bath at 120°C;

[0068] 2) After the reaction in step 1) is finished, the reaction product is cooled and filtered, and the toluene solution with a mass concentration of 180 mL of 99% is used for centrifugal cleaning, and then the acetone solution with a mass concentration of 180 mL for 99% is used for centrifugal cleaning, and then at 110° C. Dry for 5 hours;

[0069] 3) Weigh 5g of nitrilotriacetic acid and 5g of the reaction product obtained in step 2), dissolve in 450mL of pyridine solvent, and stir under reflux for 5h in an oil bath at 100°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com